Zortrax, with the support of the European Space Agency (ESA)*, is working to develop a technology that enables 3D printing high-performance composite parts out of two blends of PEEK filament

in dual extrusion on the Zortrax Endureal industrial 3D printer. After nearly a year of research

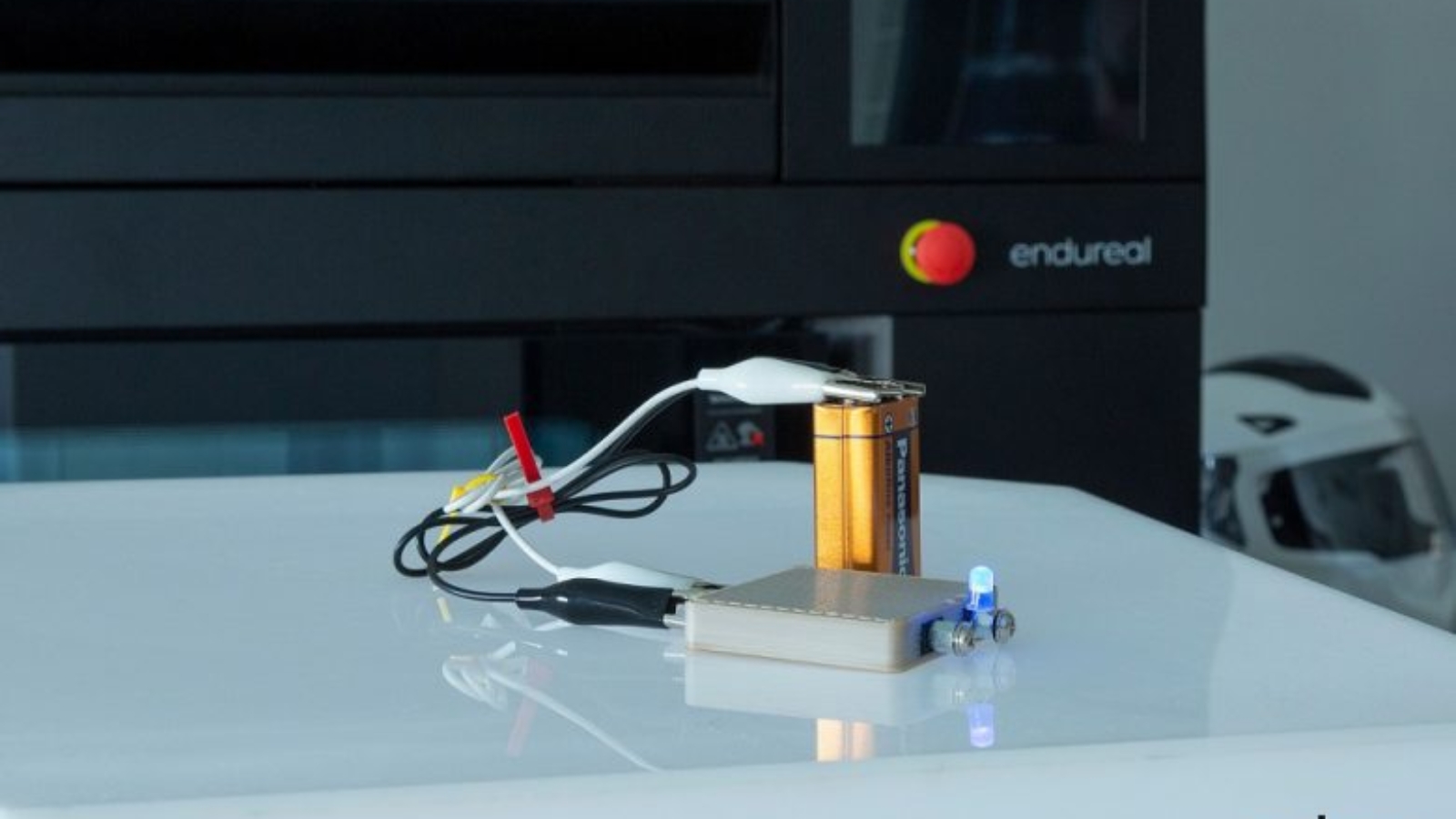

and development efforts, the first prototype composite parts made out of standard PEEK and experimental electrically conductive PEEK, developed by ESA, have been successfully fabricated on the Zortrax machine.

The LPD Plus dual extrusion technology used in the Zortrax Endureal has been traditionally used to print support structures out of different materials than the model itself. However, across the aerospace sector, there is an increasing demand for high-end composite parts 3D printed out of two high-performance polymers. This is exactly what has just been achieved. To highlight what is possible with this new solution, Zortrax engineers used ESA’s experimental blend of electrically conductive PEEK in combination with pure PEEK to print proof-of-concept models with simple electricity and data transfer features on the Zortrax Endureal.

“Reducing weight is always one of the key design goals in aerospace engineering and it can be done

by building parts that serve multiple purposes at once. In a standard airplane or spacecraft, you need to include both structural elements and wiring responsible for transferring energy or data between various systems. That is what we aim to solve with 3D printing PEEK components with electrically conductive paths. This way, the structural parts can at the same time perform electricity or data transfer functions without weight penalty incurred for additional wires. Imagine casting a solid steel slab that also works as a USB connector. That’s what the Endureal can do with high-performance polymers,” said Michał Siemaszko, Head of Research and Development at Zortrax S.A.

Printing composite models have been made possible because the Endureal’s impressive specs were bumped even further. Zortrax engineering team managed to increase the rigidity of the extrusion system which translated into even better dimensional accuracy. Other hardware changes resulted in the Endureal’s reaching even higher operating temperatures. The top extrusion temperature now stands at 480 °C. Maximum temperatures in the printing chamber and on the build platform can reach 200 °C and 220 °C, respectively, to further reduce warping and shrinkage of high-performance materials. Printing composite parts out of two materials also required innovative changes in both firmware and software.

Manufacturing on Demand

“The technology we are developing opens up a clear path to use the Zortrax Endureal for 3D printing smart components with built-in electrical circuits, all while retaining excellent thermal and mechanical properties of high-performance polymers like PEEK. This will make this printer a powerful tool in the hands of engineers and designers working for high-end and demanding applications like automotive, aerospace and space. We also expect groundbreaking solutions developed in projects like this one to quickly trickle down to our production level 3D printers” said Rafał Tomasiak, the CEO of Zortrax S.A.

And this trickling down has already started. All changes and improvements that have been made to the printer’s design to enable dual extrusion 3D printing using pure PEEK and conductive PEEK developed by ESA are already implemented across the board in all commercially available Endureal machines. The customers can rest assured that the printers they ordered will come ready to print composite models after a simple software update when the technology reaches the production level.

*The view expressed herein can in no way be taken to reflect the official opinion of the European Space Agency.

You might also like:

NASA JPL provides more details about Perseverance Rover’s 3D printed metal parts: Using 3D printing allows engineers to play with unique designs and traits, such as making hardware lighter, stronger, or responsive to heat or cold. “It’s like working with papier-mâché,” said Andre Pate, the group lead for additive manufacturing at NASA’s Jet Propulsion Laboratory in Southern California. “You build each feature layer by layer, and soon you have a detailed part.”

* This article is reprinted from 3D Printing Media Network. If you are involved in infringement, please contact us to delete it.

Author: 3D Printing Media Network

Leave A Comment