Even as the transition to metal and ceramic binder jetting for production has only but begun, it is clear that simply implementing fast binder jetting processes will not be enough to truly cater to production demands. Binder jetting materials and processes still present several challenges and bottlenecks that need to be addressed, from the limited number of available materials to the elevated number of highly complex post-processing steps, including infiltration and of course sintering. That’s exactly what UK-based Meta Additive intends to address with its uniquely advanced technology.

All the big players in the segment are working on it: Desktop Metal has developed advanced software for effective sintering and ExOne has introduced nano-particled binders. XJet has taken it all a step further by directly jetting the metal nanoparticles, further blurring the lines between binder jetting and material jetting. However, all these approaches still fall somewhat short and a new company, whose very name means change and evolution, is ready to introduce a new approach that will address all these issues through chemistry.

As an industry media, we tend to look primarily at the machines that make up current AM markets. As journalists, however, we are particularly fascinated by systems that are pushing the limits of technology and science. Yes, science. It is becoming increasingly clear that AM mechanics can only take us so far and that the next evolutionary step for AM will be more and more tied to tailored material chemistry. Meta Additive does that at a molecular, micro and nanometric level, by jetting binders made of structural materials onto more structural materials.

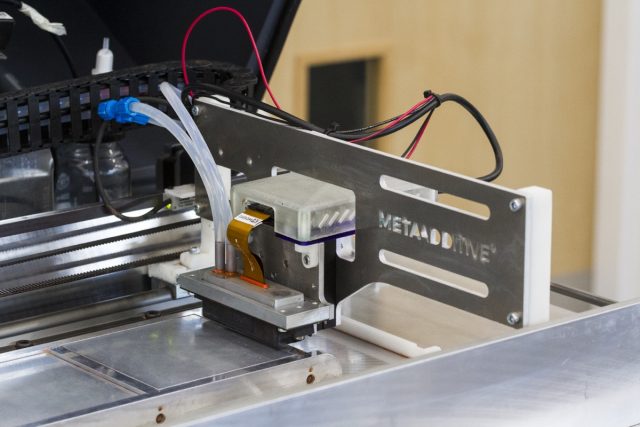

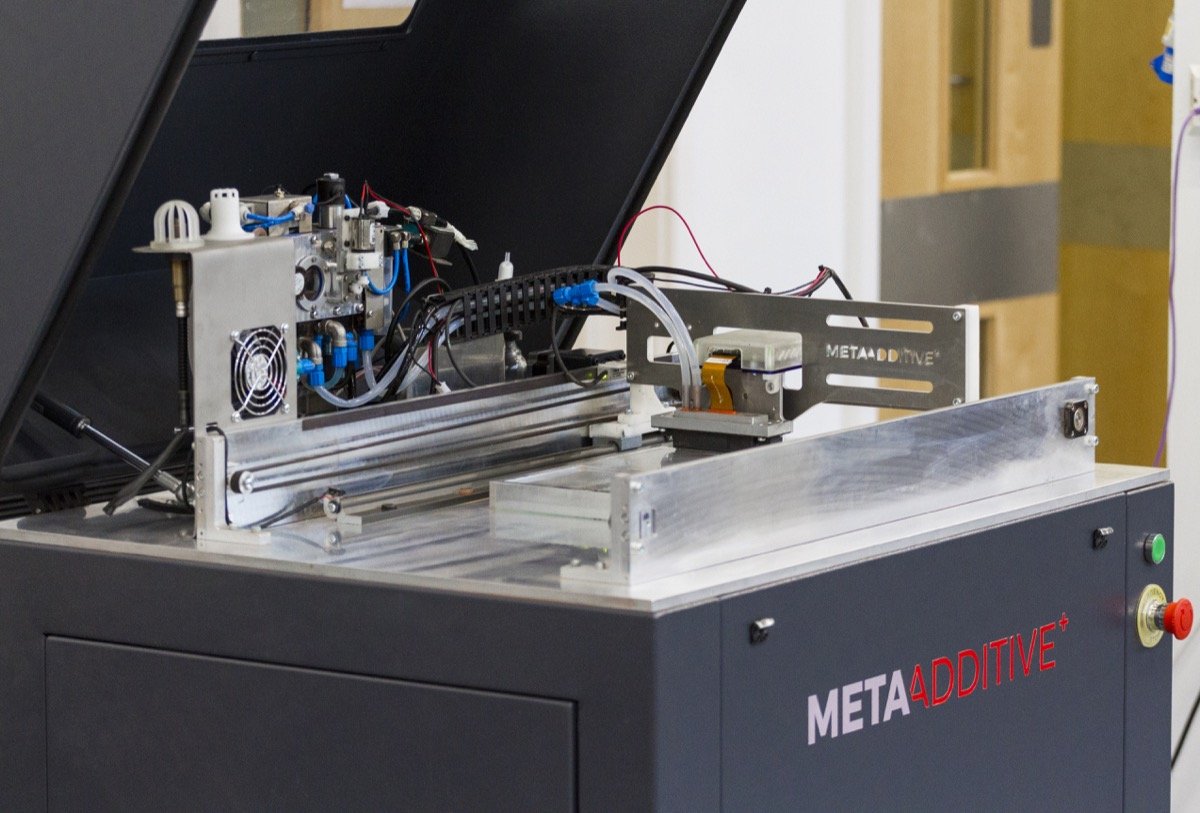

Meta Additive does that by creating a new system that is based on jetting technology as the ideal intersection of hardware, software and material science. We recently had the opportunity to interview Meta Additive Co-founder and CTO, Dr. Kate Black, to understand exactly what comes after binder jetting and what powers the companies upcoming binders and React 125 3D metal and ceramic 3D printer.

In its own meta category

“Meta Additive was founded in 2019 as the result of a research project that I started at Liverpool University as an academic initiative, Dr. Black tells 3dpbm. “My business partner and Co-founder, Simon Scott, was the managing director for Renishaw Additive Manufacturing Products Division (AMPD), so he comes from a metal PBF background and then went on to work as a consultant on metal binder jet printing for ExOne.”

The company is connected with and has a base at the University of Liverpool but the company has its main headquarters in Stoke-on-Trent in Staffordshire. This was the core of the UK’s ceramics business and a world-leading pole for both traditional and technical ceramics. The company’s HQ is inside a ceramics factory that was built in 1850.

“We made a distinct decision to move into a building like that rather than an industrial site on the outskirts of the city,” Dr. Black explains. “We want to breathe new life into the AM technology, but also breathe life back into this region and bring ceramics back to Stoke-on-Trent. But we also believe our technology can help move the traditional ceramics industry in a different direction”. One of these new directions is metals: with Meta Additive’s technology, the same processes used for ceramics can be applied to metals. This is one of the reasons why the company started working with key materials for AM, such as copper and titanium.

Changing the game

“We say our technology is a bit like binder jetting ‘on steroids’, Dr. Black says. “We are searching for a different terminology that could help users and the wider AM community understand the difference.” In a sense, Meta Additive’s technology is following the trend that sees all jetting technologies—even powder bed-based ones such as binder jetting—become increasingly hybridized for further leveraging the inkjet head’s voxel control capabilities.

Manufacturing on Demand

“Conventional binder jetting uses a sacrificial binder to bind powder, ceramic or metal powder, in a bed,” confirms Dr. Black. “Then the part needs to be debound and undergo heat treatment. We don’t have a debinding step because we are not binding with sacrificial material. We’re binding and simultaneously infiltrating with build material. The binder itself is made out of either metal components or ceramic components, depending on what you want to do.”

The origin of Meta Additive’s process can be traced back to Dr. Black’s experience with a process called Atomic Layered Deposition, which works with atom-thick of all sorts of materials, including really complex ceramics and complex metal alloys. This experience gradually evolved from 2D to 3D printing.

“We use what we call a ‘hierarchical binder’,” Dr. Black explains. “because it’s made up of a molecular component, a nano component, and a micro-component. We don’t have any sacrificial polymeric binder that we need to get rid of. The nanoparticles are there to fill in the interstices, the pores of the powder in the bed. Then we have a molecular component and that is the key to Meta Additive’s technology. It’s designed so that we know how it will react when it sees a surface and we can tailor it at the molecular level so it can react how we want it to. Similar to XJet and ExOne’s processes, the nano-particle component then fill in the pores in the bound powder materials from the powder bed so that Meta’s process is simultaneously binding and infiltrating.

One obvious benefit of this approach is much less part shrinkage during sintering. Whilst traditional binder jetting processes can see part shrinkage of up to 20% and require lengthy debinding and infiltration to achieve densities of 98% and 99%. Meta Additive can control the density and porousness of each part to a great extent and see shrinkage rates as low as 2%, which is a true game-changer. Even before sintering, after they come off the printer, the parts are already fairly hard, with densities of up to 88%. “That’s because—Dr. Black explains— there’s been a real chemical reaction, a real metal bond that formed during the printing process. The heat treatment is implemented only to consolidate the rest of the microstructure to achieve the exact microstructure you want.”

The React 125 ecosystem

Meta Additive’s first printer is called React 125, where the number refers to the size of the build platform. Given the background of the development team, the initial project was just to sell binder materials as repeat consumables to AM hardware companies that would implement them. “However—Dr. Black tells us—we realized that we needed to have full control of the hardware, software, and materials aspects so we decided to work with a software team to get the ecosystem together and we decided to produce our own hardware.”

The React 125 will make its official debut at Formnext in November. The company’s initial business model is to work with select clients in both metals and ceramics manufacturing on 12-month evaluation periods. “They get a React 125 and a 12-month binder development program,” Dr. Black anticipates. “We develop a binder system for their specific needs, which enables us to broaden our binder offering, and also understand what the real end-user requirements are and fine-tune the specific building materials for their applications.”

Binder jetting is raising expectations as a true, next-gen production process. Some call it additive manufacturing 2.0. But in order to truly deliver on those promises, the technology will increasingly need to look at fine-tuning the chemistry of both materials and processes. Voxel level control, which already happens in polymer 3D printing, needs to also happen in metal and ceramics additive production and one way to achieve this is through greater control of the inkjet heads, of what comes out of them and of what they jet the materials on.

Said of the hierarchical binders, the initial base material that Meta Additive is introducing are going to be metals: copper, titanium and aluminum. The company already started to look at advanced ceramics such as alumina, titanium carbide and silicon carbide. “We want to work with partners to understand what their challenges with the materials are, particularly in ceramics, because they’re quite different to the metals industry. The beauty about Meta technology is that it is easily transferable to a whole range of materials,” Dr. Black explains. “The same material that can be slightly tweaked to either be a metal or a ceramic. You need to have a suitable powder in the bed, but most of the material work is done in the inkjet head.”

From meta to extra

Another benefit of Meta Additive’s technology is that it can be scaled up and has no inherent limits in build size. In order to understand exactly how large it can go, the company received an Innovate UK grant for £1.2 million. “We’re scaling everything up,” Dr. Black says, “We are now looking at parts as large as two meters and of course we are looking at doing multi-material parts. I think that’s one of the most exciting things that this technology will enable us to do: imagine you have one material in your powder bed, the organic, metallic molecular element is another material, the nano-element another, and the micron-element yet another. We are beginning to see how we can build quite a complex materials system.”

Potential short- and medium-term application segments include the energy sector, for batteries, heat sinks, integrated electronics and a number of other components that can benefit from voxel-level control on a gradient of materials, from metals to ceramics, in a single part. “We believe the future of our technology will allow that to happen.

* This article is reprinted from 3D Printing Media Network. If you are involved in infringement, please contact us to delete it.

Author: Davide Sher

Leave A Comment