While conventional manufacturing technology has delivered in-country products on a global basis for decades – it has often involved dedicated, high-cost production assets and personnel that lack flexibility. Supply chain issues with procurement, as well as production lag times inherent to technologies like casting, can further add to costs and delayed delivery of conventionally manufactured products.

Metal AM promises to provide on-site legacy-part replacement in weeks rather than months. It could also be more efficient and environmentally friendly to start with the powdered alloy feedstock used to manufacture metal AM products rather than sourcing end-conditioned materials and shaping them with traditional forming methods. In addition to this, as we already know, the geometric freedom that AM technology promises creates opportunities to reimagine legacy designs. Multiple parts can be consolidated into single-piece, highly complex components that are optimized for performance rather than manufacturability. Alloys that are difficult to work with using conventional manufacturing methods can be 3D printed more easily – ensuring higher part quality delivered using less material. With faster turnaround times than many current manufacturing technologies, metal AM can offer supply chain agility, and scalable, on-demand delivery.

An ambitious goal

The ideal solution is a single, digital print file that produces the same result on different AM machines in different locations, anywhere in the world. This enables scalable production that gives manufacturers the confidence that they can produce the same parts within specification, now and at any point in the future, on any like machine without requiring additional development. Yet, while metal 3D printed parts are already proving their worth in the air, space, power plants, and under both ground and ocean, no metal LPBF provider has been able to demonstrate repeatable AM distributed manufacturing on a global scale – until now.

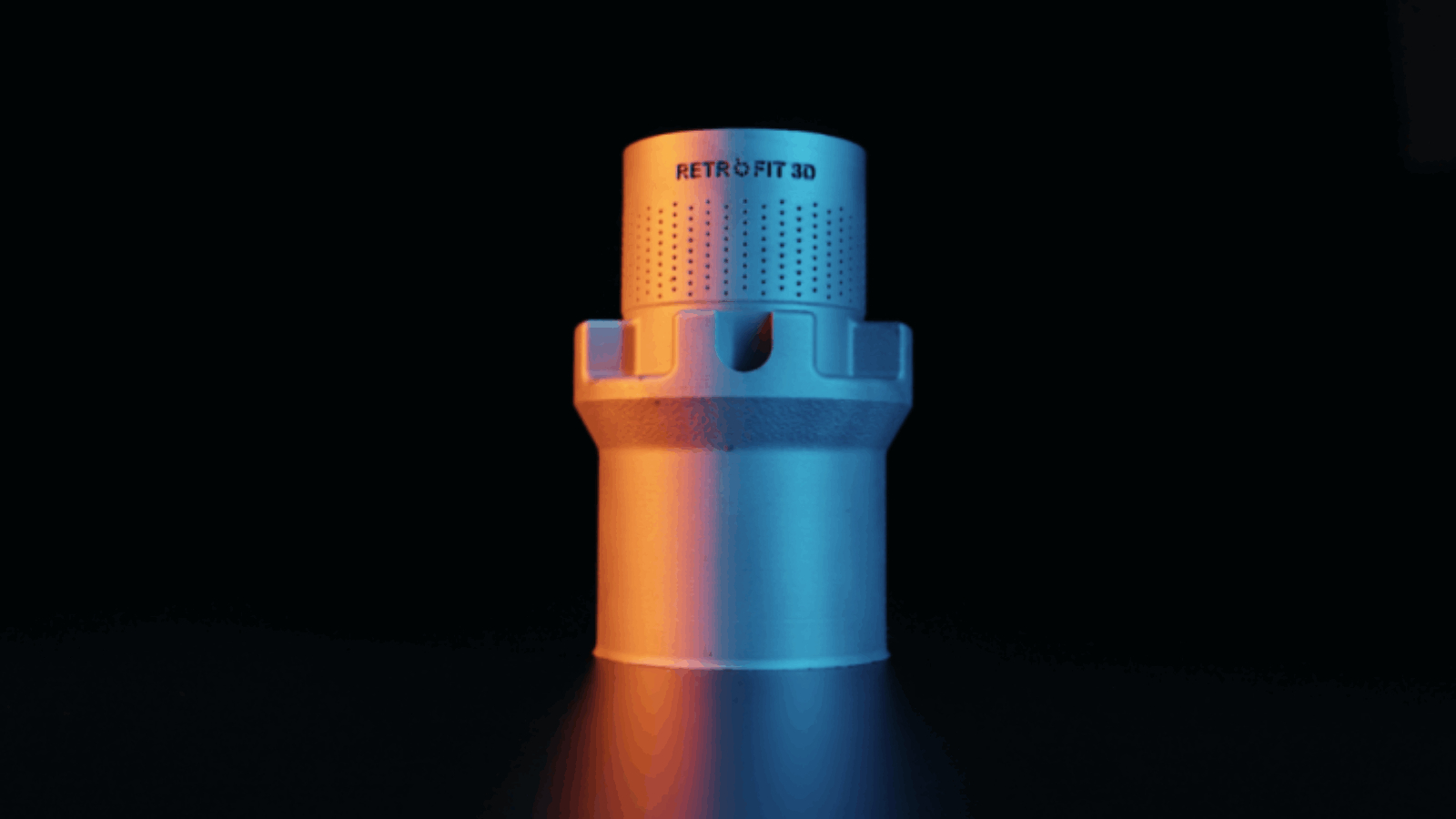

Following the successful production and field-service deployment of a metal AM oil & gas part with a major North American company in 2021, IMI Critical and Velo3D worked together to expand this work to a distributed-manufacturing project. The goal of the project was to prove that Velo3D Sapphire printers could solve the production scalability and readiness problem that many AM platforms have struggled with – producing the same parts within specification across different printers, using the same print file, without any further development efforts. If successful, it would give IMI Critical the confidence they could scale their production accordingly to reliably produce the same parts across any Sapphire printer in the world using the same print file.

A decade of experience with ever-advancing AM technologies, and the success of their earlier work with Velo3D, gave IMI Critical the confidence to pursue the distributed-manufacturing project. “This one-year wait between finalizing the new valve design, and then deciding to print more of it at different locations, simulates the kind of fear that everyone in a global manufacturing company has,” said Steve Freitas, director of new product development at IMI Critical. “Time has passed, and you need to produce the same design in quantity again, but how can you be sure it’s going to be within specification without additional development and certification efforts?”

How did they do it?

The existing Velo3D print file from the 2021 project, which includes the entire instruction set for 3D printing, was pulled from IMI Critical’s PLM system, securely sent to six manufacturing sites across three continents (four in the US, one in Asia, and one in Europe).

The CMs involved were Stratasys Direct Manufacturing (Austin, TX), Duncan Machine Products (Duncan, Oklahoma), Knust-Godwin (Katy, Texas), Avaco (South Korea), and Schoeller Bleckmann Oilfield Equipment (SBO, Austria). The sixth print run was performed at Velo3D headquarters in California.

Manufacturing on Demand

Here’s how the project was carried out:

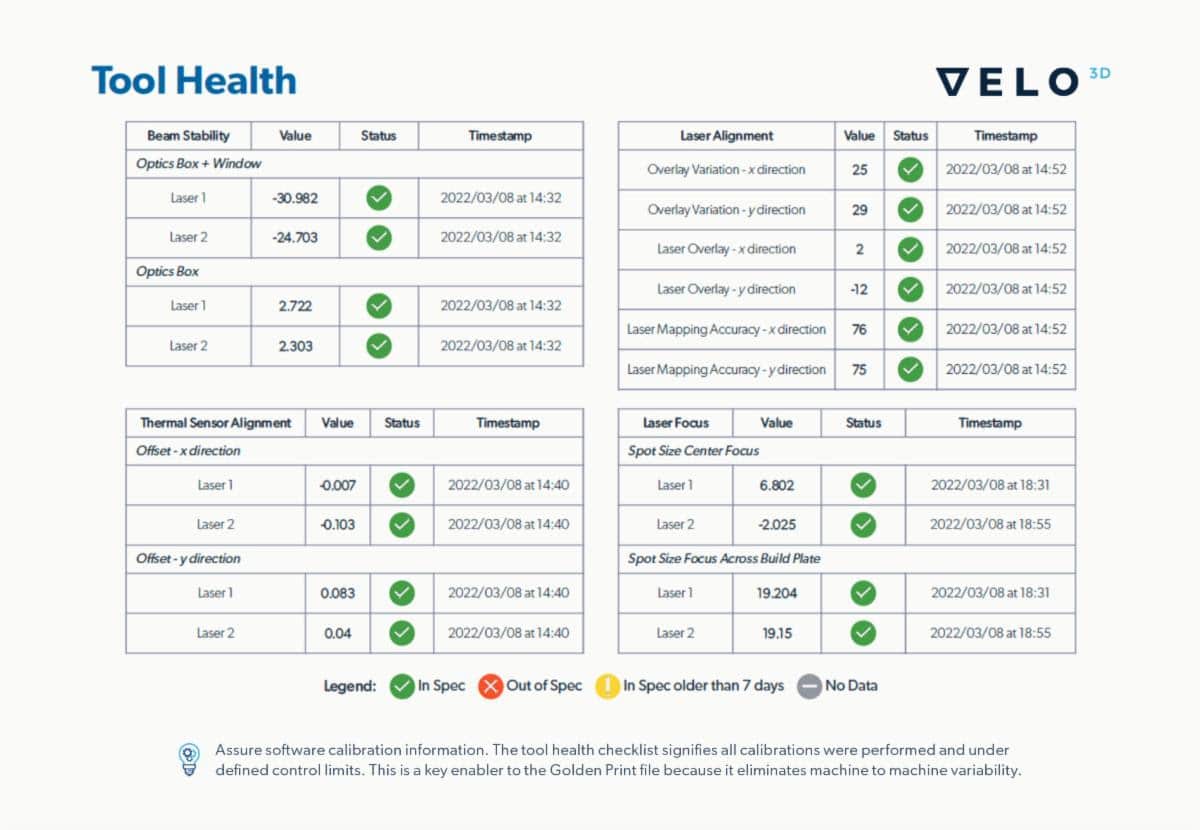

- At each CM site, the Velo3D Sapphire system went through a series of calibration checks to ensure predictable and consistent print outcomes.

- The locked “Golden Print File” was loaded into each Velo3D Sapphire system; its set of laser instructions could not be altered at the CM site. This was the original print file, with no alterations, from 2021, that was created using feature-based parameters assigned by Flow, Velo3D’s print-preparation software.

- Each build contained two parts and was printed on-site. Both the calibration processes and print execution quality are monitored by Assure, which is embedded in every Sapphire system.

- Excess powder was removed from the parts after each build.

- The parts were then stress-relieved and removed from the build plate. Additional heat treatments and machining were conducted at each location.

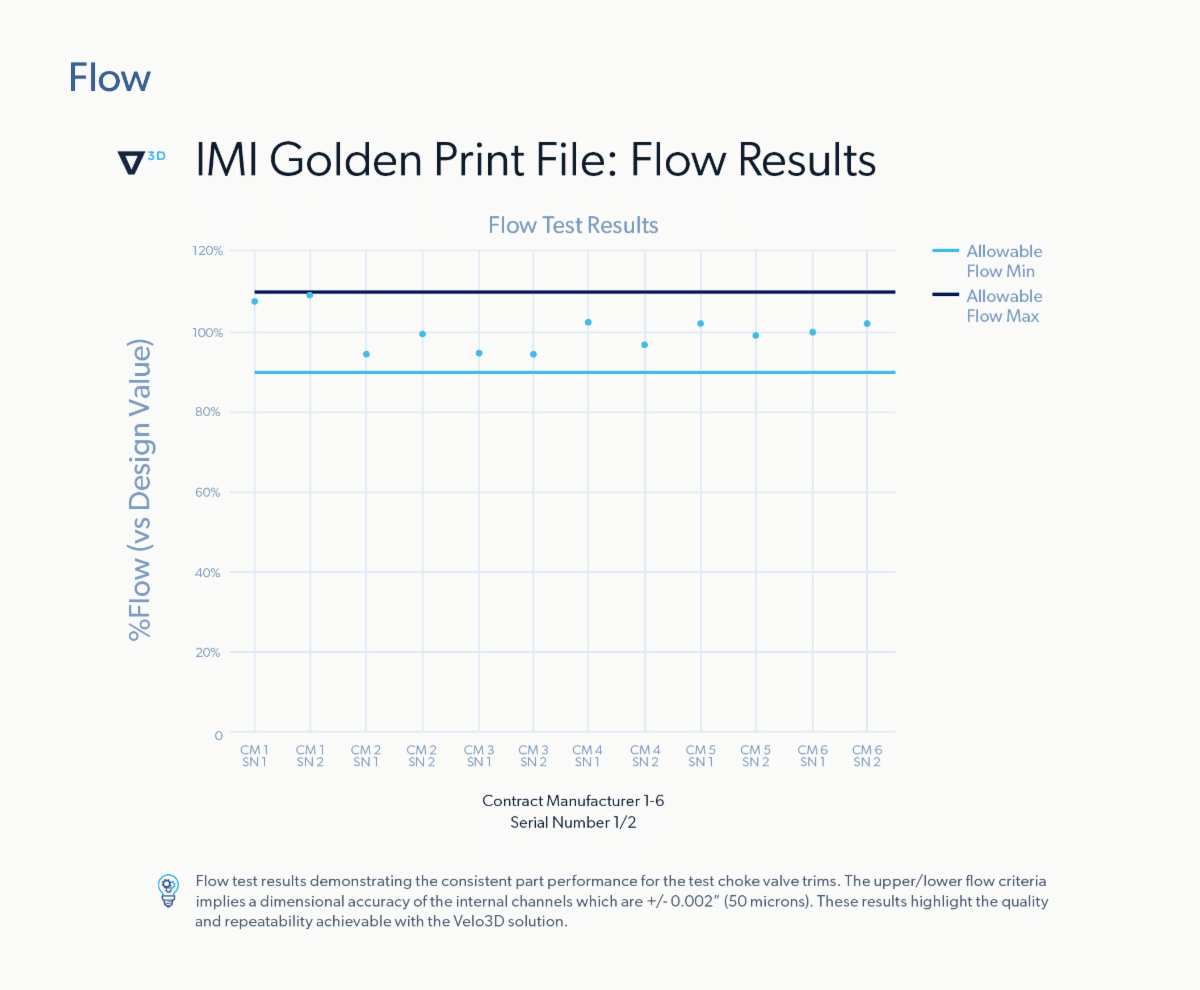

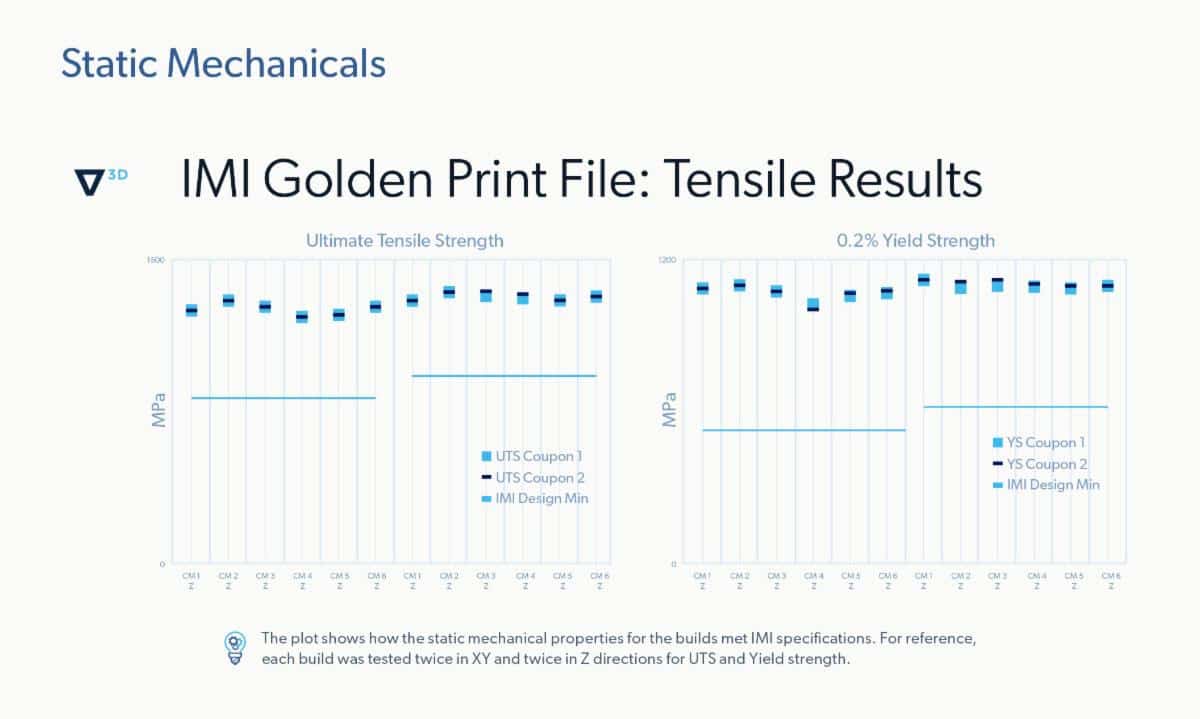

- The parts then went through strict quality control that included the dimensional inspection, mechanical testing, and flow testing of each valve.

The results

Following the completion of the steps outlined above, the collation of data for the 12 printed parts, two parts from each of the six production locations, has now been completed. The results conclude that the mechanical testing and flow testing – along with destructive and non-destructive evaluation of the material coupons – demonstrates that all of the parts, both metallurgically and functionally, met IMI’s design and performance specifications.

“We now have the confidence, whether it’s two weeks from now or two years from now, to print that same print file at any of these suppliers in the future,” said Zach Walton, director of technical business development at Velo3D. “With the Digital Product Definition, spelled out in API20S as a collection of data required to reproduce the additively manufactured component, unchanged from the 2021 project, this demonstrated the ability to not have to requalify or redevelop – which is a big win for the O&G as well as other industries trying to deploy distributed manufacturing.”

These results are an important benchmark in demonstrating that distributed manufacturing using advanced metal laser powder bed fusion (LPBF) technology is achievable in the real world.

Applicable in any industry

“Now that we’re scaling up our retrofit business around the world, we recognize the value of having an end-to-end AM solution that allows for scaled production without compromising quality and repeatability,” said Steve Freitas. “We find the Velo3D approach to be very attractive in that regard. We don’t have to reinvent the wheel each time because we have qualified build recipes and print file instructions that are locked. It also saves costs due to not having to repeat qualification. This maintains IP for the print instruction file, which is increasingly important as we deploy globally.”

The company has already moved on to other projects using the Velo3D network of CMs – 3D printing parts such as a 12-inch gas-letdown valve for an offshore facility, and a 10-inch boiler feed-pump valve for supercritical power plants.

“We now have a more scalable supply chain for our global customers,” said Steve Freitas. “Velo3D’s technology can print our legacy designs without having to requalify on new machines, allowing us to ramp production up and down as needed. That’s very effective for us, given our huge library of reference parts. We can also innovate more extensively as we update legacy designs. And we can now print really large parts, up to 24-inch diameter, with the new, larger Sapphire XC system. We’re very excited about the work that’s going on here and the way forward.”

“Whether you are working in space, defense, power, or any other industrial environment, if you want to reproduce either an individual spare part, or a larger number of optimized, high-performance components, you may have similar future scalability problems that AM – and a worldwide network of CMs – can now successfully solve,” said Zach Walton.

You might also like:

Robb Hudson appointed as CEO and President of MELD PrintWorks: In this position, Robb Hudson will be responsible for ensuring PrintWorks’ customers receive outstanding printed parts produced with the MELD technology. He will lead the PrintWorks team to meet the needs of customers – including those who struggle to obtain forgings, castings, and other metal parts due to time constraints and supply-chain issues.

* This article is reprinted from 3D Printing Media Network. If you are involved in infringement, please contact us to delete it.

Author: Edward Wakefield

Leave A Comment