The Additive Manufacturing Association in German Engineering Federation VDMA is developing a roadmap for additive manufacturing which details the path towards Industry 4.0.

As part of the research for this VDMA project, participants identified post-processing for 3D printed parts as the stage which needs the most development. Christoph Hauck, Chairman of the Board of the VDMA Additive Manufacturing Association and Managing Director of MBFZ Toolcraft GmbH, comments, “Only automation of the various work steps will allow for economical and sustainable production with additive manufacturing technologies,”

“It is here in particular that research and development need to be advanced so as to strengthen the competitive position of AM technologies. The experience gathered as well as integration of traditional manufacturing technologies all offer a large potential for optimization.”

The potential for serial production

Last year, members of the Additive Manufacturing Association within VDMA began compiling a roadmap sketching out the way to automate manufacturing processes for industrial 3D printing.

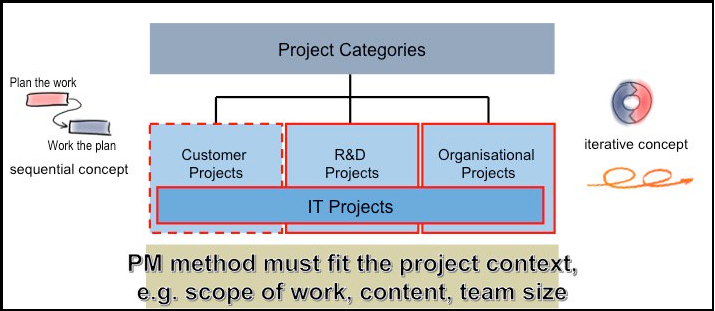

“In our working group Automation, we have manufacturers of AM systems, industrial users, suppliers of software and automation solutions, as well as representatives from science, all working together,” explained Rainer Gebhardt, project manager at VDMA.

“If you look at it closely, you will find already today hotbeds for comprehensive automation and a consistent in-process quality control. We need to make them available to industrial users as quickly as possible.”

Following their research, members of the VDMA Additive Manufacturing Association saw the potential for series production using additive manufacturing, as well as a high degree of willingness from the association for fast industrialization. “Against this background, our discussion process has developed a very special dynamic,” added Gebhardt.

The VDMA Additive Manufacturing Roadmap

The VDMA Additive Manufacturing Association consists of 150 members from companies and research institutes covering the steps of the additive manufacturing value chain. The association also includes suppliers of post-processing and automation solutions.

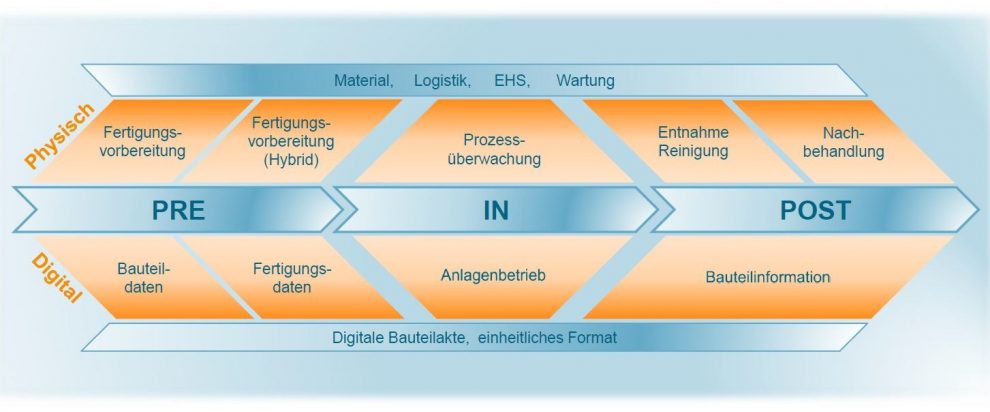

Looking at previous additive manufacturing roadmaps, the association identified R&D issues in materials logistics, the EHS area, data processing, and process standardization.

“We are convinced that our roadmaps provide an accurate summary of the work schedule for the next years,” stated Dr. Markus Heering, Managing Director of the VDMA Additive Manufacturing Association.

“Now, politically responsible persons of vision and innovative fellow campaigners from diverse sectors are needed for us to quickly work through this programme. We need to watch out so that we will not waste our good starting position and then watch the innovation train leave without us.”

For the latest additive manufacturing news, subscribe to the Industry newsletter. Also, find us on Facebook and like us on Twitter.

Looking for a career change? Search and post new opportunities across additive manufacturing by visiting Jobs.

Featured image shows a depiction of connected technologies. Image via the VDMA.

Leave A Comment