Scientists at Rice University and the University of Maryland (UMD) have outlined a new proof-of-concept for 3D printing artificial bone tissue. With results published in , the hope is that such tissues may one day help to damage related to arthritis and sporting accidents.

Sean Bittner, a third-year bioengineering graduate student at Rice, National Science Foundation fellow and lead author of the paper, said “Athletes are disproportionately affected by these injuries, but they can affect everybody.”

“I think this will be a powerful tool to help people with common sports injuries.”

3D printing osteochondral tissue

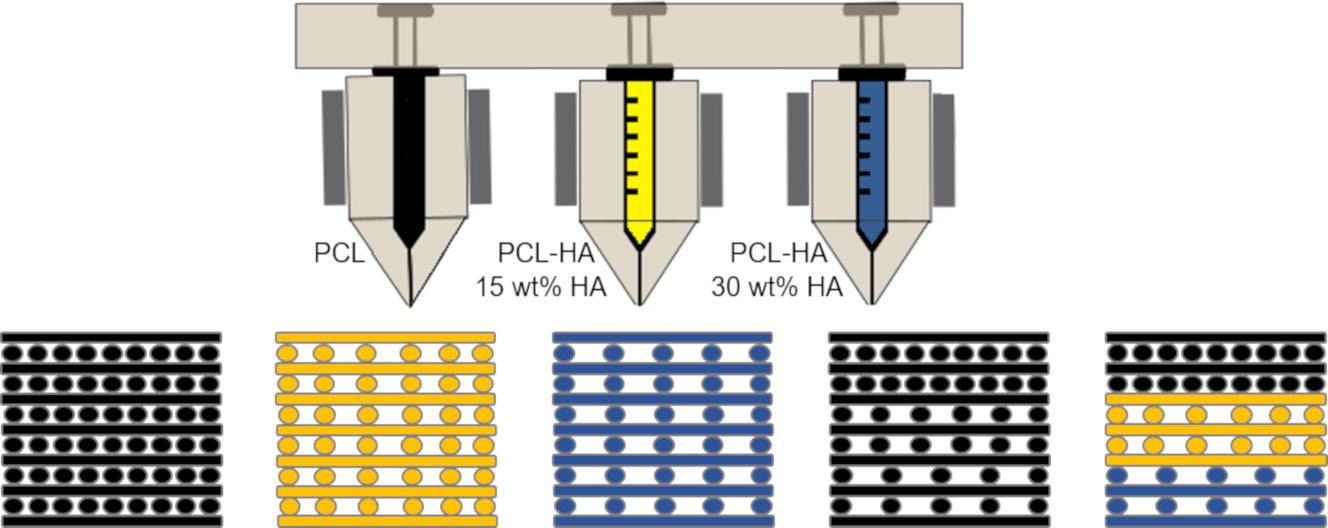

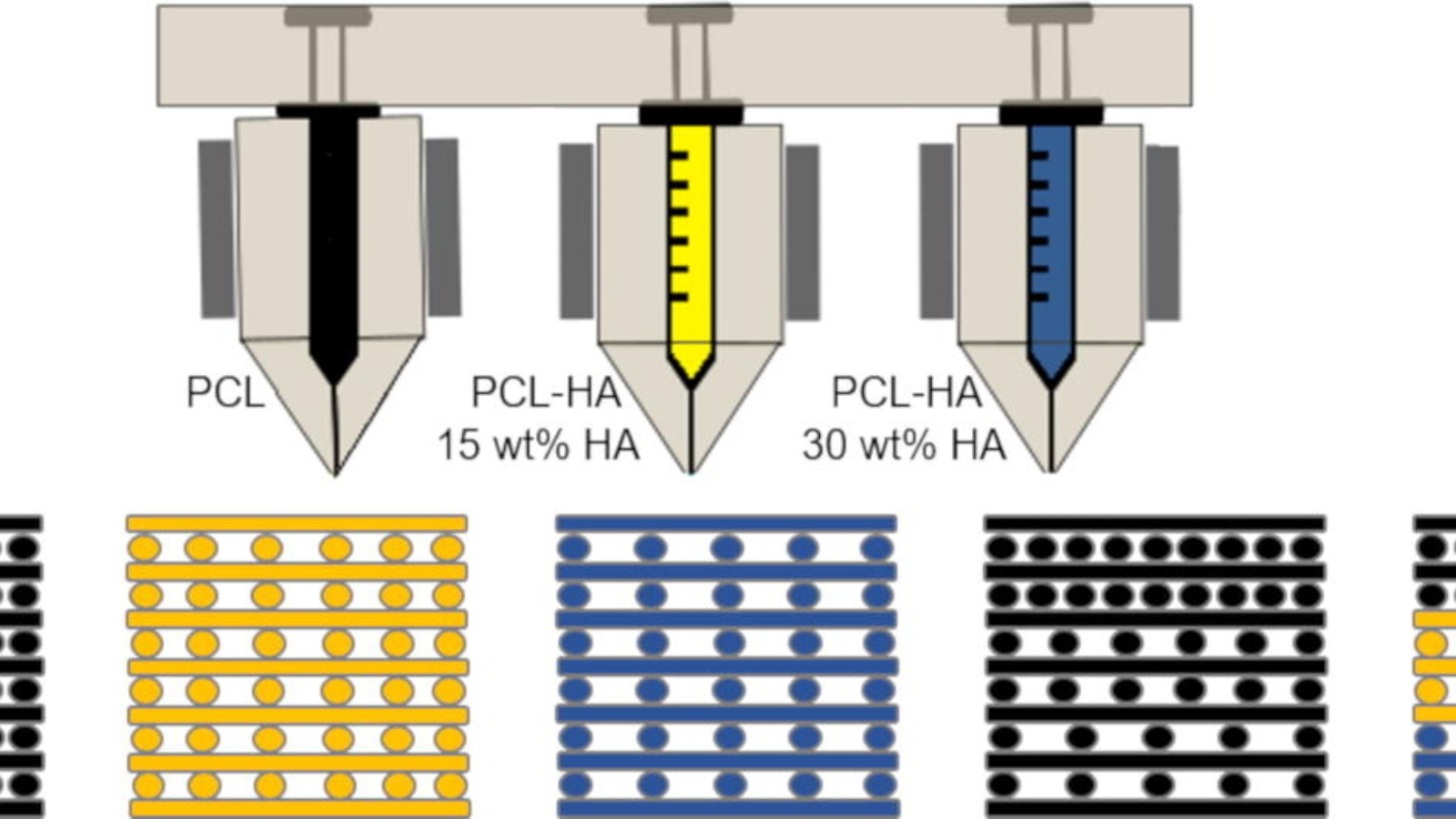

Rice and UMD’s artificial bone concept uses 3D printed cell scaffolds. Created at the Rice Biomaterials Lab, these experimental structures were made from a custom mixture of polymer and ceramic material. The design followed in 3D printing was created to mimic the structure of osteochondral tissue with imbedded pores.

The end result is a material that mimics both cartilage (chondral tissue) and bone (osteo). After drying, the scaffolds underwent rigorous compressive tests, where they proved to be mechanically comparable to natural bone.

Eventually, by applying such scaffolds to the body, the goal is to improve the treatment of injuries where small cracks and pieces of theses bones break off. Potential advantages of such implants include the ability to encourage the in-growth of cells and blood vessels. “For the most part, the composition will be the same from patient to patient,” explains, Bittner, “There’s porosity included so vasculature can grow in from the native bone. We don’t have to fabricate the blood vessels ourselves.”

3D printing the way to healthy bones

Manufacturing on Demand

This latest research adds to a growing collection of studies in 3D printed bone. In some cases, studies have already been conducted on ways to create 3D printed implants that dissolve as a bone heals. Scientists and surgeons at NYU School of Medicine and NYU College of Dentistry, New York for example managed to demonstrate that 3D printed implants can be used to regenerate bone across small holes in the skulls of mice and missing pieces of rabbits limbs and jaws, up to 1.2 cm long.

Other studies have included in-situ 3D printing directly at the point of an injury (as opposed to an implant).

The future of 3D printed bone

The future of the joint Rice-UMD project will involve figuring out how to 3D print implants that perfectly fit the intended patient, while still allowing it to grow into and knit with the bone and cartilage.

“Moving forward, the technique described here will serve as the template for more complex multimaterial constructs with bioactive cues that better match native tissue physiology and promote tissue regeneration,” state the authors.

Antonios Mikos lead bioengineer and one of the authors of the paper adds, “What we’ve done here is impactful and may lead to new regenerative medicine solutions.”

Full results of this study, titled “Fabrication and mechanical characterization of 3D printed vertical uniform and gradient scaffolds for bone and osteochondral tissue engineering,” are published in . The paper is co-authored by Sean M.Bittner, Brandon T.Smith, Luis Diaz-Gomez, Carrigan D.Hudgins, Anthony J.Melchiorri, David W.Scott, John P.Fisher, Antonios G.Mikos.

* This article is reprinted from 3D Printing Industry. If you are involved in infringement, please contact us to delete it.

Author: Jack Colyer

Leave A Comment