Ultimaker, a Netherlands based 3D printer manufacturer, has expanded operations within the APAC region with a new office facility in Singapore.

Following this, Benjamin Tan, former Channel Director at Dassault Systèmes, has been appointed as Vice President Asia Pacific at Ultimaker in Singapore.

“There is a greater understanding of additive manufacturing in Asia Pacific,” said Tan. “And, as per Wohlers Report, AP is poised to take a 30% share of the global 3D printing space. We will leverage our business development efforts to target AP multinationals, and work closely with them to improve the supply chain.”

The next revolution of manufacturing

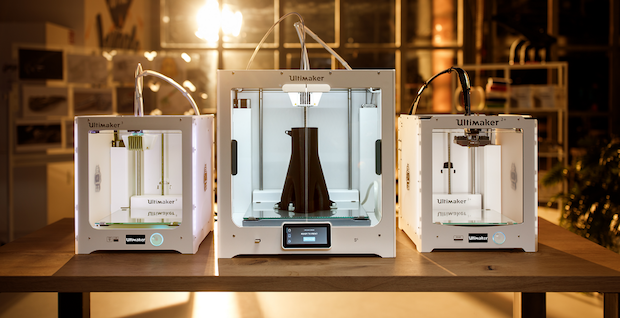

From research into 3D printed self-forming structures, to cost and time-efficient spare-part production for machinery, Ultimaker has spent the last seven years developing its range of desktop 3D printers for a variety of applications.

The company’s latest 3D printer, the Ultimaker S5, which has the largest build volume (330x240x300mm) within Ultimaker’s 3D printer series, illustrates the increased focus on meeting industrial production demands.

“3D printing is not only used for prototyping anymore,” said Jos Burger, CEO of Ultimaker.

“It is a reliable and accessible technique that is now causing the next revolution in manufacturing.”

“We see a growing demand for Ultimaker 3D printers in the APAC region from enterprise clients and innovative SMEs. By opening office facilities in Singapore, we can better manage these demands locally, and support our well-established APAC Sales Partner Network in taking the next step in accelerating the world’s transition to local digital manufacturing.”

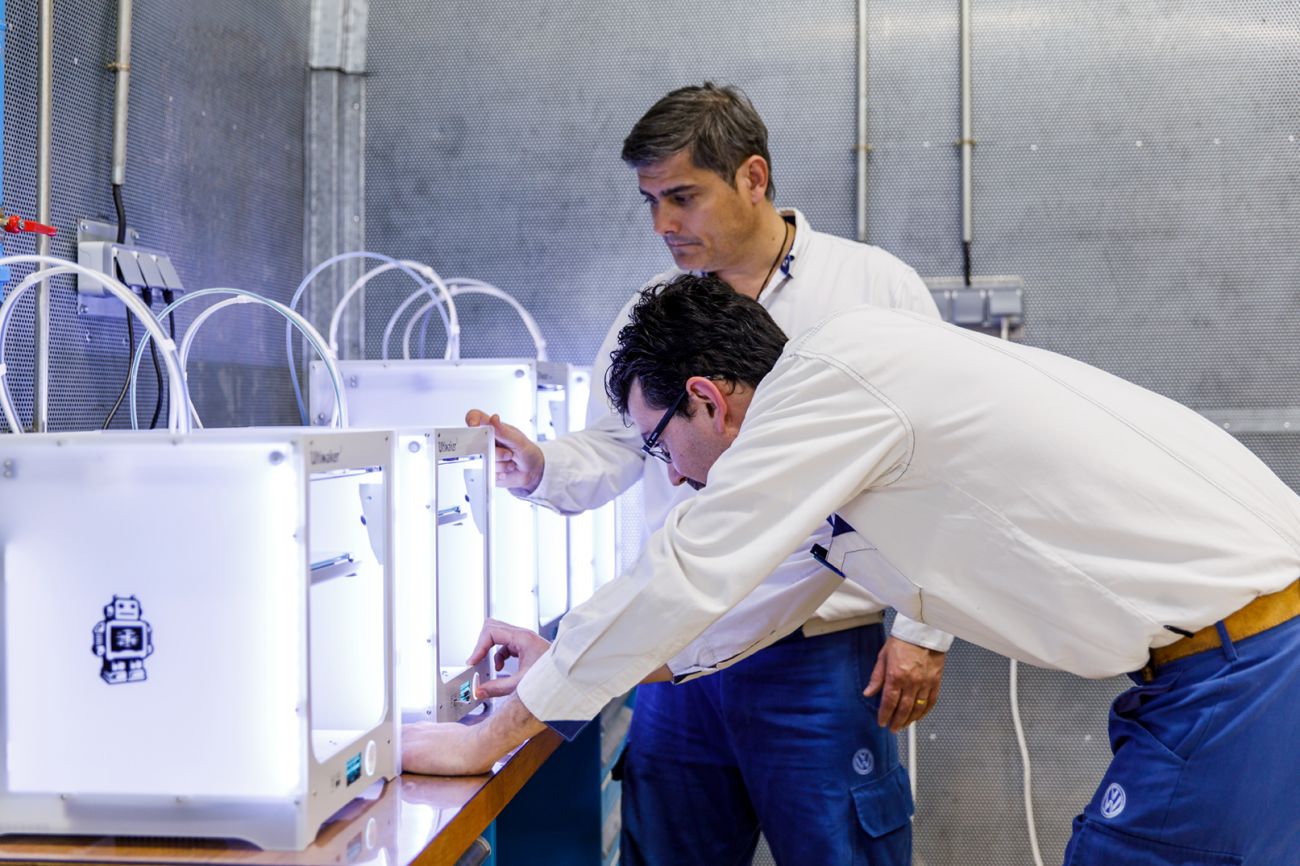

Ultimaker helps Volkswagen save $160,000

Last year, the Volkswagen Autoeuropa, an automotive assembly plant in Portugal, announced annual savings of $160,000 by using seven 3D printers, which includes the Ultimaker 3 and Ultimaker 2+.

The plant, which employs 4,000 people, turns around 100,000 vehicles, was able to reduce typical production costs by over 90% and tool development time by 95% through the production of an estimated 1,000 3D printed tooling parts.

The liftgate badge tool, used to accurately apply a car’s model name, was one of many components produced using 3D printing. As a result of 3D printing, the plant’s initial investment was recouped within 2 months.

Earlier this year, Ultimaker received the Industry Award for automotive application as a result of its work with Volkswagen Autoeuropa. Prior to this, Ulitmaker received the 2017 Industry Award for OEM of the year.

Meeting global demands

With the increased global demand for Ultimaker 3D printers Tan, sees a strong potential for developing 3D printing as an industry in the APAC region.

This expansion confirms Ultimaker’s dedication to its clients and solidifies the statements made by CTO and Co-Founder Siert Wijnia, in a recent interview with Industry:

“For us, we’re committed to doing all we can to promote 3D printing and its development, which means making our technology available to everyone.”

Catch up with the latest 3D news by subscribing to the Industry newsletter. Also, follow us on Twitter, and like us on Facebook.

Looking for a new job in the 3D printing industry? Find the latest vacancies from Ultimaker and more on our Jobs service.

Featured image shows the opening Ultimaker’s Singapore office with Siert Wijnia (CTO), Benjamin Tan (VP APAC), Jos Burger (CEO) and Paul Heiden (SVP Product Management). Photo via Ultimaker.

Leave A Comment