The U.S. Army Combat Capabilities Development Command Chemical Biological Center (DEVCOM CBC) and the University of Hawaii System recently formalized a collaborative initiative to enhance warfighter survivability and effectiveness. This partnership, strategically focused on leveraging biomaterials and advanced manufacturing capabilities, aims to strengthen defense efforts, particularly in support of the United States Indo-Pacific Command, which is headquartered in Hawaii.

Collaborative Framework and Key Initiatives

This joint effort operates under a cooperative research and development agreement (CRADA) and two initial joint work statements (JWS). These agreements enable both organizations to work together on diverse projects, ranging from sophisticated “organ-on-a-chip” scientific tools to broader advancements in manufacturing and repair processes.

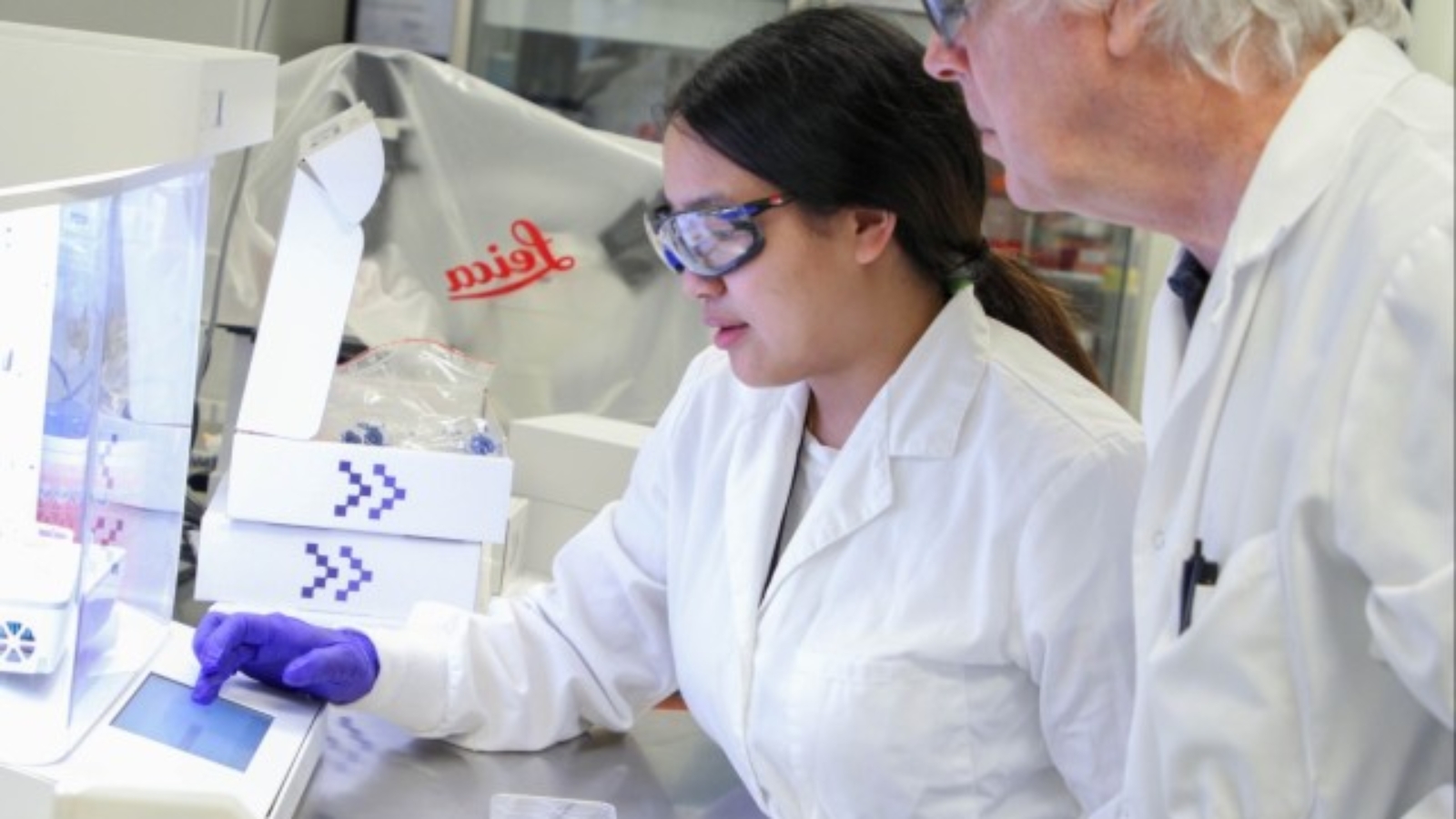

Under the first JWS, executed on March 14, Dr. Jason Barnhill, an associate research professor at the University of Hawaii at Mānoa’s John A. Burns School of Medicine (JABSOM), is collaborating with Priscilla Lee, a DEVCOM CBC bioengineering researcher. Their joint aim is to develop sophisticated organ models for evaluating various compounds critical to the Department of Defense. This research, an integral part of the new CRADA, specifically leverages bioprinting to enhance existing in vitro organ models. The goal is to improve protections and treatments for warfighters against severe threats, including burns, poisonous gases, antibiotic-resistant bacteria, and other chemical-biological hazards.

Lee’s research at DEVCOM CBC concentrates on bioprinting cell culture models to study immune responses and develop next-generation biomaterials. This new partnership will advance bioprinting capabilities at DEVCOM CBC and facilitate the development of deployable printers at UH Mānoa, enabling the establishment of remote, printable prototype stations even in austere conditions.

“We are incredibly proud that Dr. Barnhill and Priscilla Lee are representing the University of Hawaii at Mānoa and DEVCOM CBC with these efforts that have the potential to save the lives of our frontline Soldiers and civilians across the world,” said Sam Shomaker, dean of University of Hawaii at Mānoa JABSOM. “By helping to introduce innovative biofabrication technology to even more remote areas, JABSOM is assisting in the mission across the Pacific and globally.”

The second JWS under the CRADA harnesses the University of Hawaii system’s extensive presence and advanced manufacturing research and development capabilities within the United States Indo-Pacific Command region. This component of the agreement focuses on collectively developing advanced manufacturing capabilities to create a more expansive regional network. This network is envisioned to bolster supply chain resilience, foster defense innovation, improve critical information sharing, and facilitate broader collaborative efforts.

US Army, Universities Collaborate on Advanced Manufacturing for Defense Innovation

Manufacturing on Demand

This collaboration is part of a wider trend illustrating the U.S. Department of Defense’s increasing academic partnerships to drive innovation in critical defense technologies.

Texas A&M University, a Public Research Institution, secured $1.6 million in funding from the Defense Advanced Research Projects Agency (DARPA) to develop a new system that accelerates the assessment of quality and durability in 3D printed parts. As part of DARPA’s SURGE program, grantees are challenged to reduce evaluation times from 18 months to just three days, while simplifying the process to run on a standard laptop. This initiative aims to facilitate wider adoption of additive manufacturing within the Department of Defense and is expected to save millions of dollars.

In 2021, the DOD awarded 18 university-led projects a total of $25.5 million to accelerate hypersonic flight research via technologies such as 3D printing, machine learning, and non-destructive testing. The research contracts, which are set to be handed out over the course of three years, were awarded to members of the University Consortium for Applied Hypersonics (UCAH). As the name might suggest, UCAH is aimed at advancing hypersonic technology development, and operates under the Joint Hypersonics Transition Office (JHTO). Awardees include participants from 28 universities, 15 industrial partners, three national laboratories, and four additional international partner universities.

.

You might also like:

UltraThineer Veneers Offer Solution for Severe Tetracycline Staining: According to Dr. Ha, the patient had tried multiple at-home and in-office whitening treatments over the years with no success. She expressed interest in a conservative treatment that would lighten her dark teeth while preserving their natural shape. Using a fully digital workflow—including intraoral scanning, virtual smile design, and additive manufacturing—Dr. Ha employed 120-micron-thick zirconia shells fabricated through BMF’s micro-precision 3D printing technology. “UltraThineer’s ability to deliver ultra-thin, highly opaque zirconia veneers—just 0.12mm thick—allowed us to completely mask the staining with no enamel reduction,” said Dr. Ha. “The esthetic result exceeded the patient’s expectations while preserving 100% of her natural teeth.”

* This article is reprinted from 3D Printing Industry. If you are involved in infringement, please contact us to delete it.

Author: Paloma Duran

Leave A Comment