Turner MedTech – a new medical technologies company with an exceptional senior level team specializing in contract manufacturing, component manufacturing, finished assembly and rapid prototyping – has announced the forthcoming release of professional and prosumer grade propriatory GMASS 3D filaments.

The feedstock is targeted to recast additive manufacturing of higher density components for metal simulation. The company states no less than: “The filaments can eliminate traditional prototyping processes such as laser sintering of metal materials by providing an easy and much more accessible alternative that developers can accomplish with common and inexpensive desktop 3D printers.”

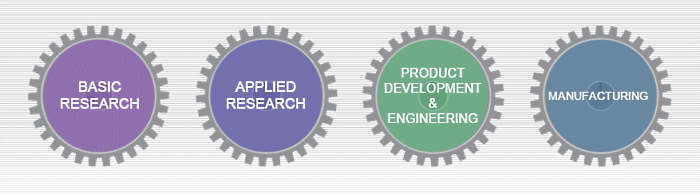

Orem, Utah-based Turner MedTech formally launched at the MD&M West Conference on the eleventh of February 2014. The organization exists in two sections: Turner Innovations, where the company’s R&D is formed; and Turner MedTech, where the company’s manufacturing is forged.

The venture provides the following services from its Utah facilities: Rapid prototyping; Computer Numerical Control machining; injection molding; manufacturing transfer; process validation; component traceability; low to medium volume electromechanical assembly; component and system level testing; final assembly and packaging; Device History Record (DHR) control; product design and engineering; Design For Manufacturability (DFM); plus product verification and validation.

The company intends to utilize GMASS to permeate the markets for the metal prototyping of medical devices, x-ray devices, consumer products and sports goods — where there is a requirement for the simulatation of weighting, balancing and baring of metals, or vibration dampening. The material fulfils a niche for components in the 2.7 to 4.0 g/cc range.

Dr. Clark Turner, Turner MedTech Founder and CEO announced: “We are extremely pleased to bring a technology to market that will serve as a catalyst for a new era of innovation in 3D printing. The new GMASS™ filaments are ideal for x-ray equipment designers and are also configured for easy use by hobbyists and experimentalists in the rapidly growing 3D printing industry as well.” The CEO also noted that GMASS can provide a faster more cost effective method to prototype components that require higher density that plastics. He provided the example of a growing x-ray equipment patron that is using GMASS to prototype an x-ray collimator design with significant time and money savings in the product development process.

Turner MedTech is to premier GMASS 3D filament at the 100th Radiological Society of North America (RSNA) annual trade show event. The event runs from November 30th to December 5th in the South Hall Booth #4079.

For your ease, the full 3DPI article archives for: Metal materials.

Leave A Comment