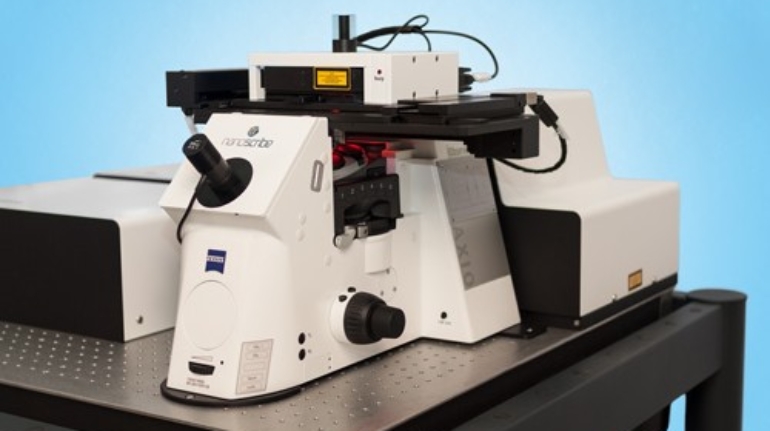

In June, the 3D printer manufacturer Nanoscribe held its first user meeting in the US at Harvard University in Cambridge, Massachusetts. In collaboration with the institution’s Center for Nanoscale Systems (CNS), which makes a Nanoscribe laser lithography system available both to internal and external users in its multi-user facility, the market and technology leader invited its clients to a two-day seminar. Besides being treated to a glimpse of the latest software and hardware developments, attendees were shown a vast array of areas of application for the Photonic Professional GT 3D printer, ranging from maskless lithography to additive manufacturing. The technological possibilities range from the manufacture of extremely high-resolution mesoscale objects to applications in photonics and plasmonics, requiring structure sizes of just a few hundred nanometers. The CEO of Nanoscribe, Martin Hermatschweiler, reports, “The presentations by our clients on their various applications were the absolute highlight for me. It is incredibly fascinating and enlightening to discover firsthand what different disciplinary fields are making use of our devices, which operate based on the principle of two-photon polymerization. The full scope of applications ranged from printing nanostructures at the CNS, to producing plasmonic displays at the University of Florida, to engineering new types of materials whose creation would have previously been impossible, as the scientists at Caltech presented.” As a standard for microfabrication, the high-precision Nanoscribe systems are furthermore utilized at universities, research institutes, and in R&D departments for many other tasks in the areas of medical technology, micro-optics and microfluidics as well as for micro-rapid prototyping. Already half of the top 10 universities across the globe are Nanoscribe clients. This makes the company the global player on the market for 3D printers of nano- and microstructures. Within a just a few years, Nanoscribe has managed to turn from a spin-off of the Karlsruhe Institute of Technology (KIT, Germany) to a medium-sized company. A broad array of honors and awards, such as the 2014 Prism Award or 2015 WTN Award as well as Nanoscribe’s finalist position for the Deutscher Gründerpreis 2015 (2015 German Founders’ Award), underscore the extraordinary performance and significance of this expanding high-tech company.