Cloud 3D Printing Software 3D PrinterOS Powers Duke Innovation CoLab’s 60+ 3D Printer Farm 3D Printer Hardware

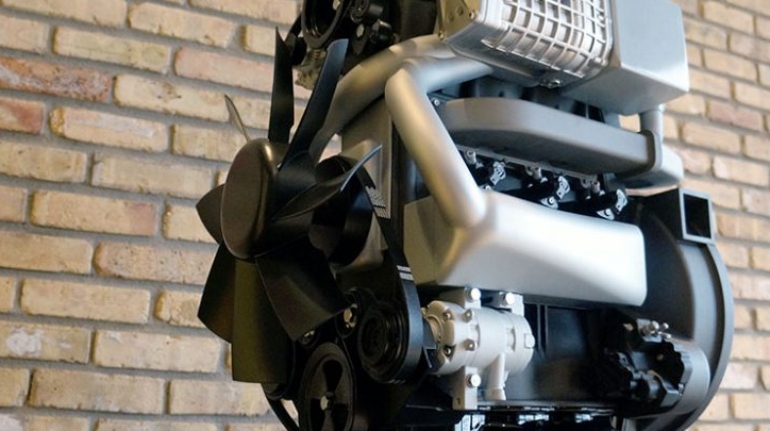

At the 3DPrintingBusiness.Directory we pride ourselves in working with some of the most fascinating and potentially disruptive companies in the industry. One of these is cloud 3D printing software 3DPrinterOS, a startup which offers what is likely to be the most advanced and complete cloud 3D printer networking system. We’ve known its founder John Dogru since the very beginning of his venture into 3D printing cloud software – and have seen his company come a long way – but don’t just take our word for it. Take renowned Duke University’s Innovation CoLab’s. The Innovation Co-Lab is a creativity incubator, focused on exploring how new and emerging technologies can fundamentally reshape the research, academic, and service missions of the university. Working with innovation-minded people around Duke’s campus, the lab is building a model program that will elevate and inspire Duke students who are solving problems, big and small, through ever-changing technological environments. Duke students of all backgrounds, interests, and skill-sets are encouraged to participate. To help the students find solutions to real everyday problems, the Innovation CoLab offers an impressive array of over 60 3D printers including literally a ton of Ultimakers, a few other interesting thermoplastic extrusion systems (MakerBot, Printrbot and a large format Gigabot), some Formlab desktop SLA systems and even a new full color mcor ARKe (find the full list here). All these 3D printers are connected to and managed by 3DprinterOS. The open platformed is licensed by OIT for all of Duke. Any member of the Duke community can use this software to manage their print jobs, even remote printing is possible. Stop into the lab to get an access code and a quick run down about how to use the system. To get started with 3D printing at Duke, there is a full online course available at Duke Extend. The course gets students up and running on the 3DPrinterOS system. Definitely worth checking it out