3DSIM launches exaSIMTM ULTIMATE for Thermal Strain Prediction Additive Manufacturing

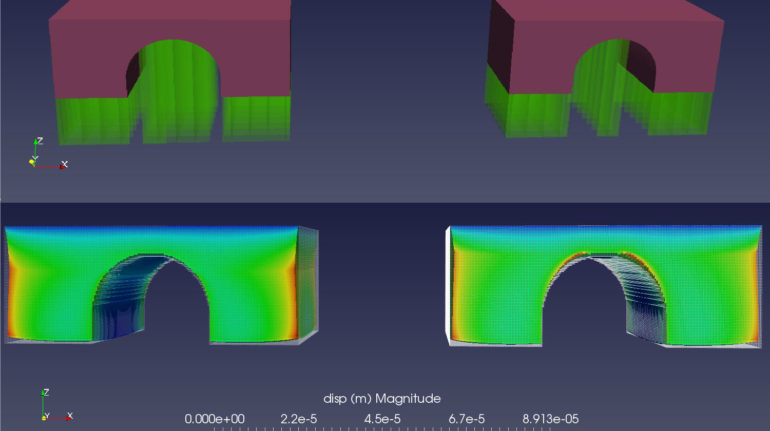

3DSIM, a company leading in the development of functional and efficient simulation software focused on predicting the AM process, launched exaSIMTM ULTIMATE, completing the exaSIM process simulation portfolio. The new software adds full part Thermal Strain predictions (which is a unique feature) to Assumed Uniform and Scan Pattern strain, enabling engineers to leverage detailed additive manufacturing (AM) science to accurately predict part dimensions, to automatically correct for distortion and optimize supports. The software also enables users to visualize the effects of part orientation, process parameters and machine differences on AM-produced parts.