Neorizon: Airbus and LM Industries form future-thinking mobility startup Research & Education

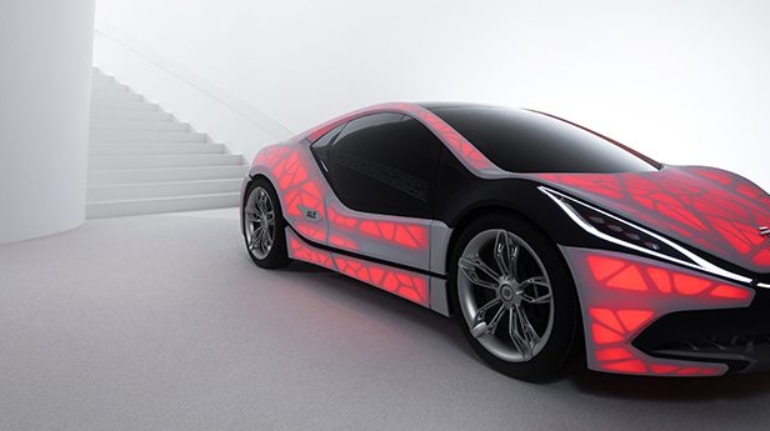

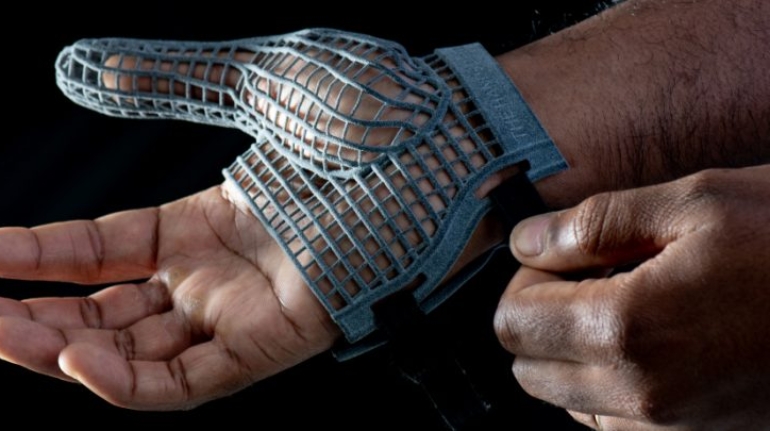

Aeronautics company Airbus has partnered with LM Industries to form a new company dedicated to local mobility and autonomy, Neorizon. The mobility startup will operate a microfactory designed to rapidly and efficiently build products for new transportation and mobility solutions.