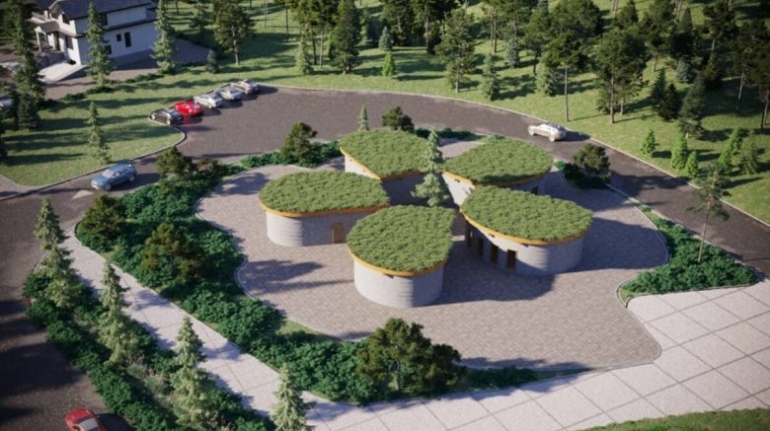

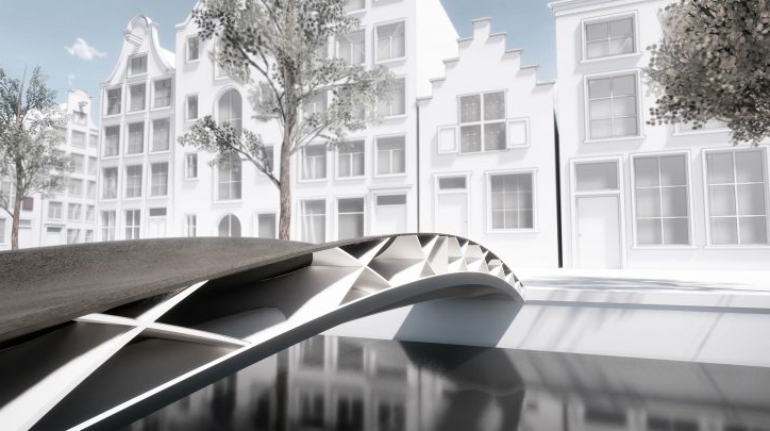

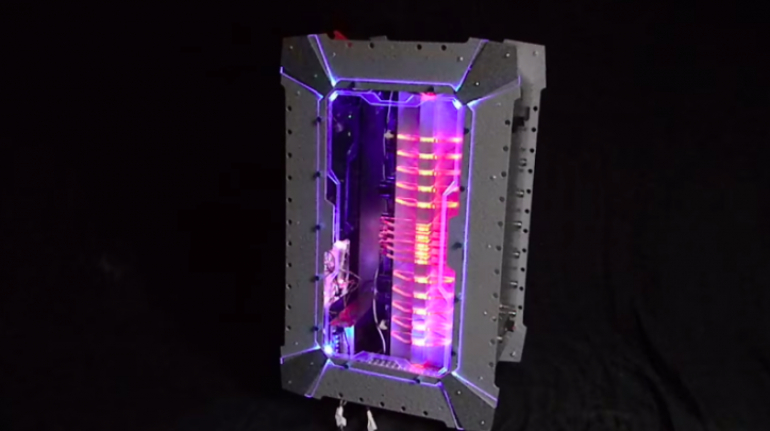

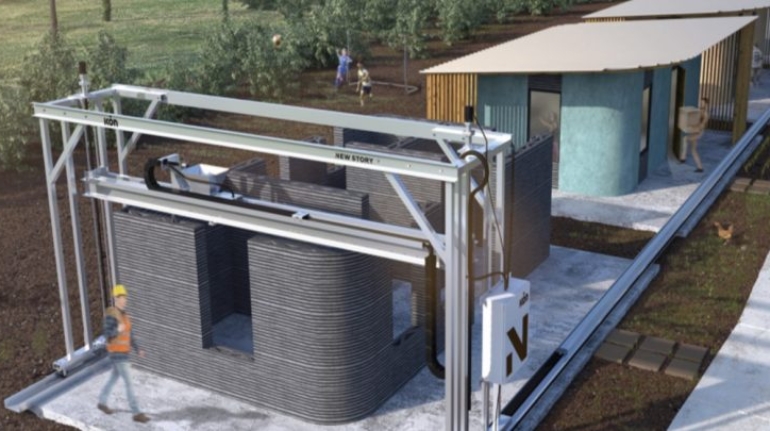

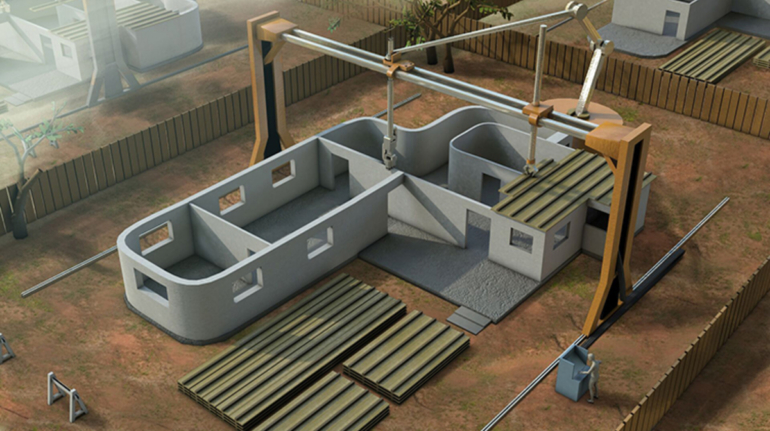

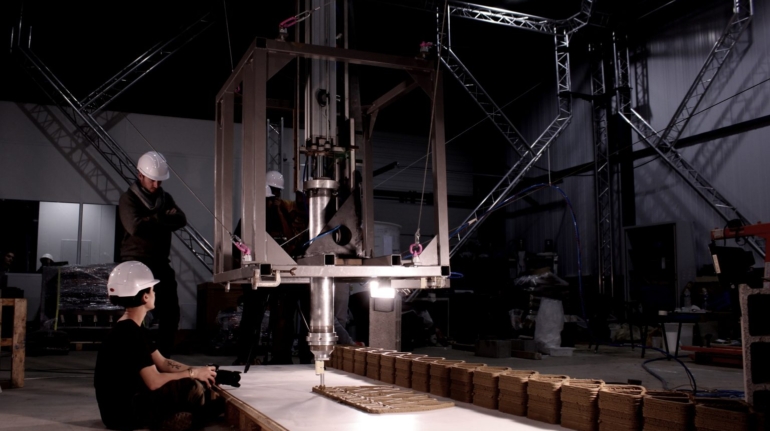

Two-story 3D printed home passes Japan’s stringent seismic standards Construction 3D Printing

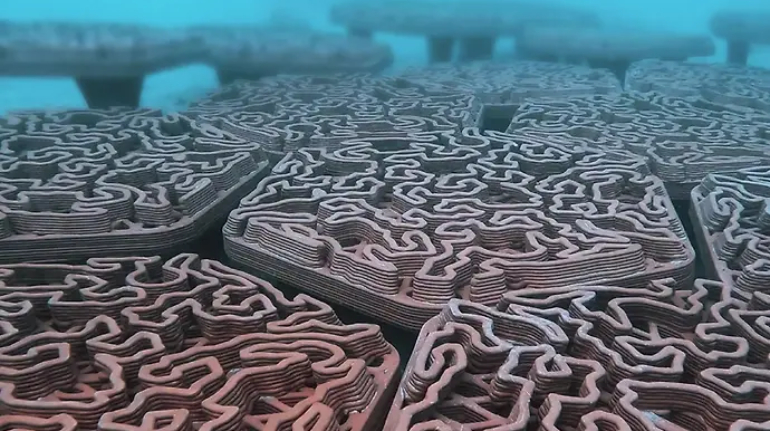

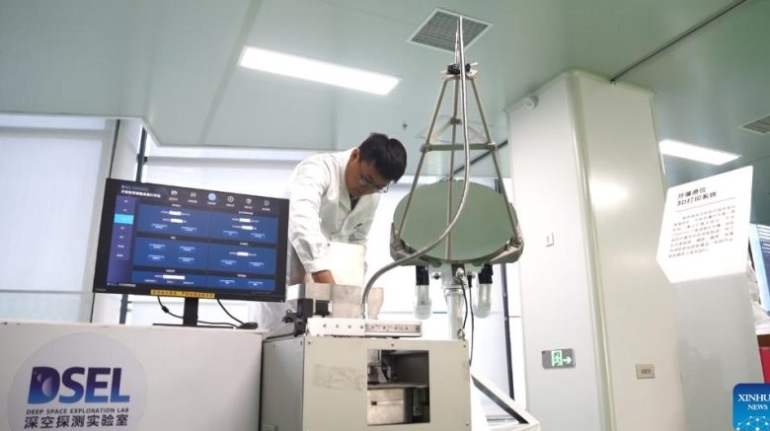

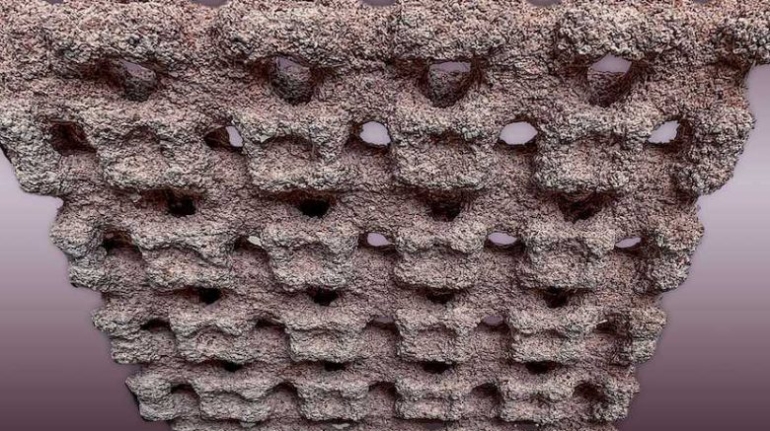

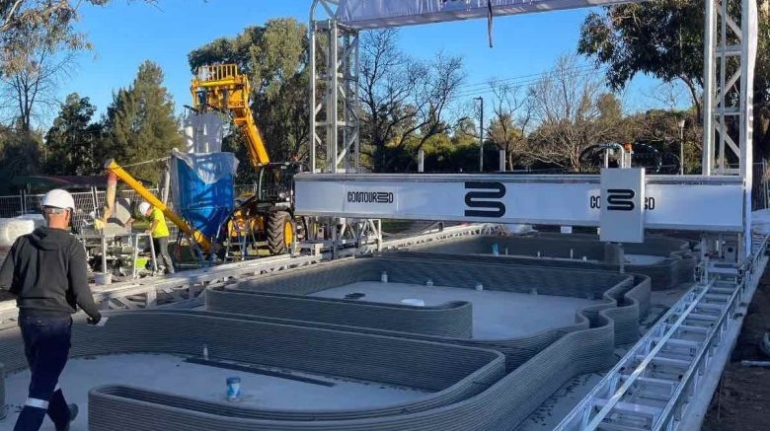

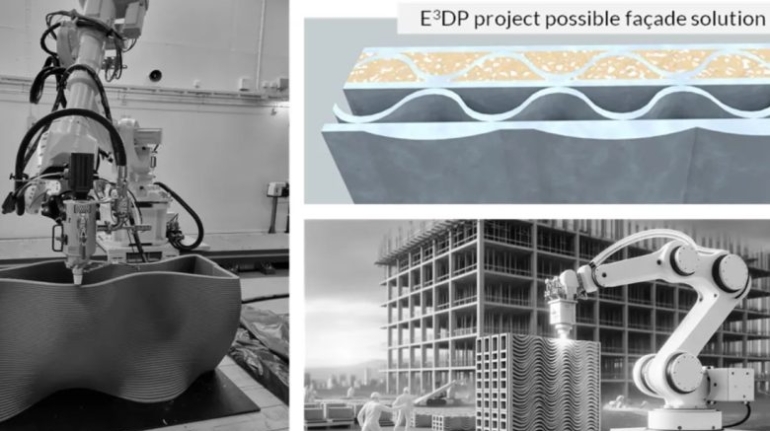

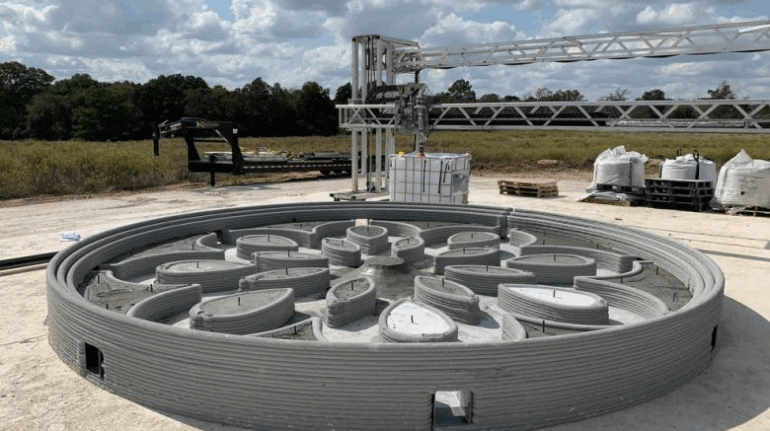

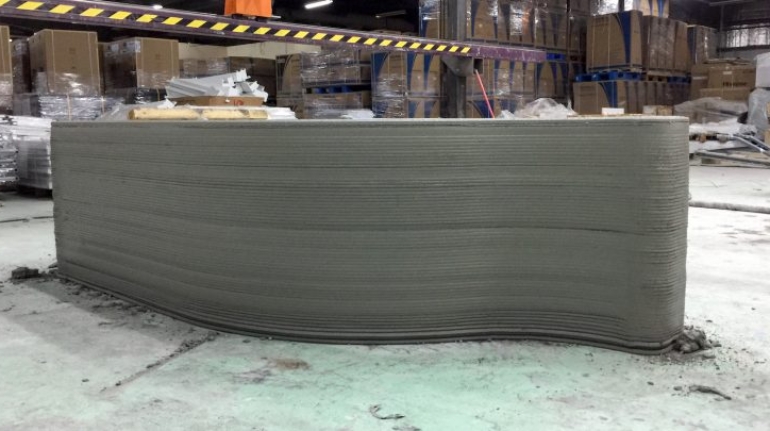

As a country that experiences upwards of 500,000 earthquakes every year, Japan is correct to have highly stringent building requirements. These requirements—the New Anti-seismic Structure Standard from 1981 in particular— ensure that only buildings with earthquake-resistant structures are erected. In a milestone for the emerging construction 3D printing sector, the first two-story 3D printed home has been approved by Japan’s government based on these standards, demonstrating that reinforced 3D printed concrete is a valid construction material for earthquake-resistant homes.