Sintavia Develops Exclusive Process for 3D Printing F357 Aluminum 3D Printing Processes

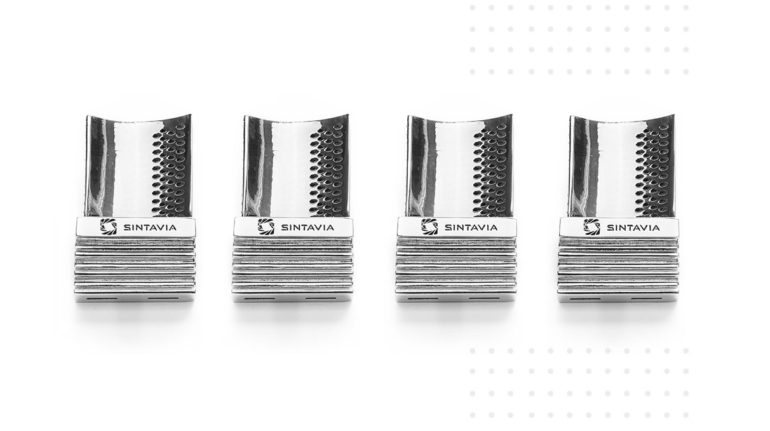

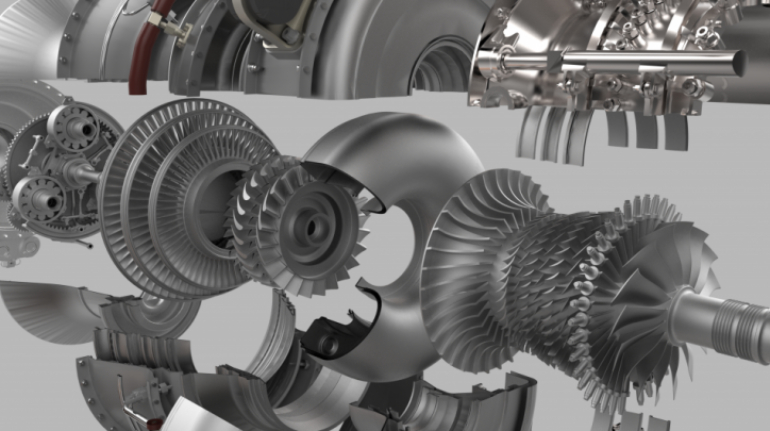

Florida based, metal AM forerunner, Sintavia, LLC, announced today that it had developed full end-to-end parameters for producing additively manufactured parts in F357 aluminum, as well as other Al-Si alloys, for use in precision manufacturing. Sintavia’s proprietary process for printing F357 aluminum powder was developed specifically to address aerospace and automotive industry needs for components with low density, good processability, and heat conductivity. Though most aluminum alloy parts are manufactured using traditional casting practices, Sintavia is changing the landscape for industries looking to expand beyond traditional manufacturing in foundry-grade aluminum alloys.