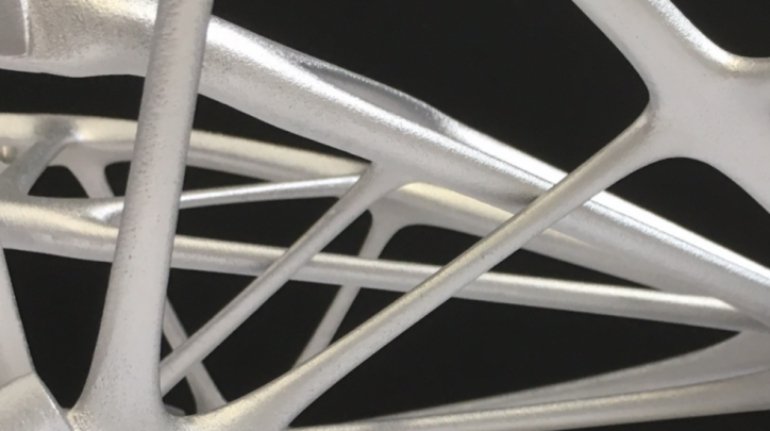

Oerlikon and RUAG working together for serial production of 3D printed space components Aerospace

Oerlikon, a leading technology and engineering group, and RUAG Space, a division of the technology Group RUAG, will sign a Memorandum of Understanding today during the Farnborough Airshow to qualify and accelerate series production of 3D printed space components.