GE Aviation already 3D printed 30,000 fuel nozzles for its LEAP engine Aerospace

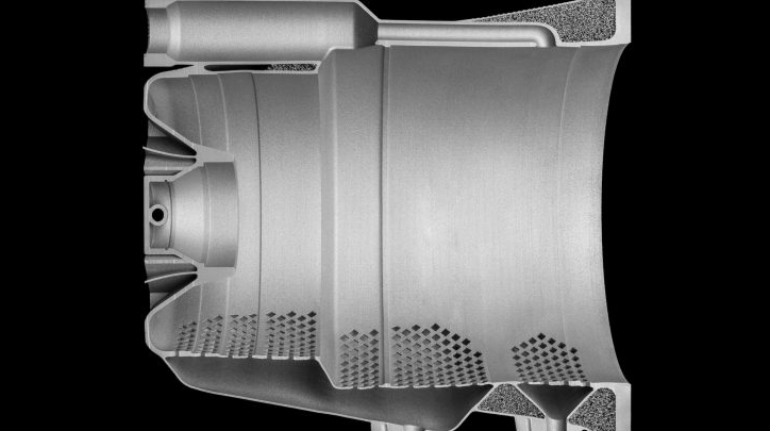

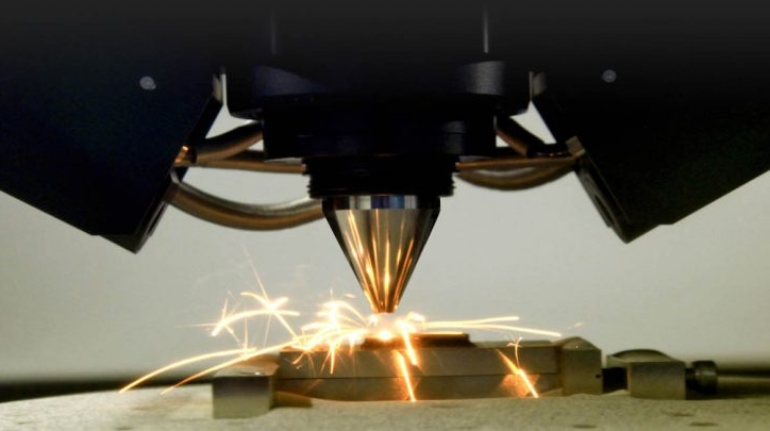

Is 3D printing truly going to become a technology for mass production? And if so, when? What and how many final parts have been 3D printed? GE is helping us shed some light on this topic. After the company’s additive and medical divisions reported that 100,000 hip cups have been 3D printed to date, now GE Aviation is reporting that 30,000 fuel nozzles have been 3D printed for its LEAP engines.