Will 3D printed SuperDraco engines stand up to Crew Dragon’s launch escape test? [update: yes] Aerospace

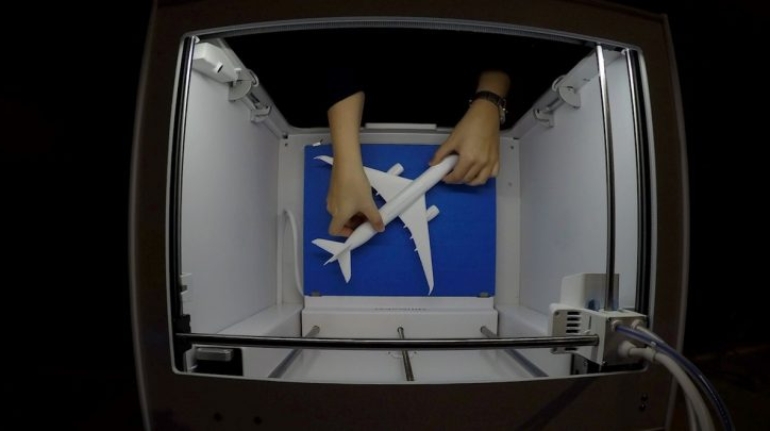

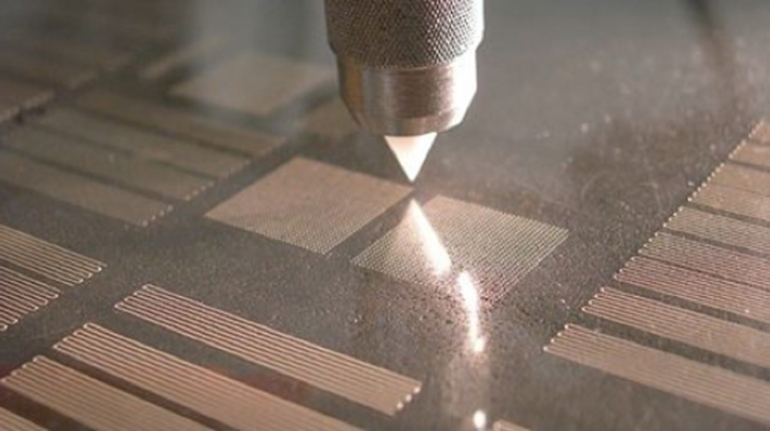

Before it can conduct manned missions to the ISS, the Moon, Mars and Beyond, SpaceX has to prove that its Crew Dragon capsule has what it takes to keep astronauts safe during the flight. One last key hurdle in this endeavor is to test the Crew Dragon’s built-in escape system. The launch escape test – which relies on the capsule’s 8 3D printed SuperDraco engines – was [update] scheduled for Sunday, January 19th. You can watch it again below.