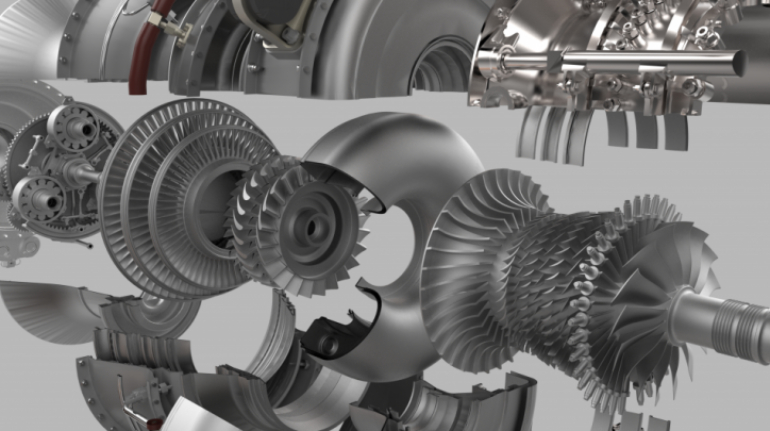

Unison to provide additively manufactured air-air heat exchangers for Cessna Denali aircraft Aerospace

Dayton, Ohio, based Unison Industries announced that it has been selected by Textron Aviation, a Textron Inc company, to provide additively manufactured air-air heat exchangers for the new Cessna Denali high performance single engine turboprop. With a maximum occupancy of 11, the clean sheet Denali single engine turboprop will be powered by GE Aviation’s Advanced Turboprop Engine and is targeted to achieve first flight in 2018.