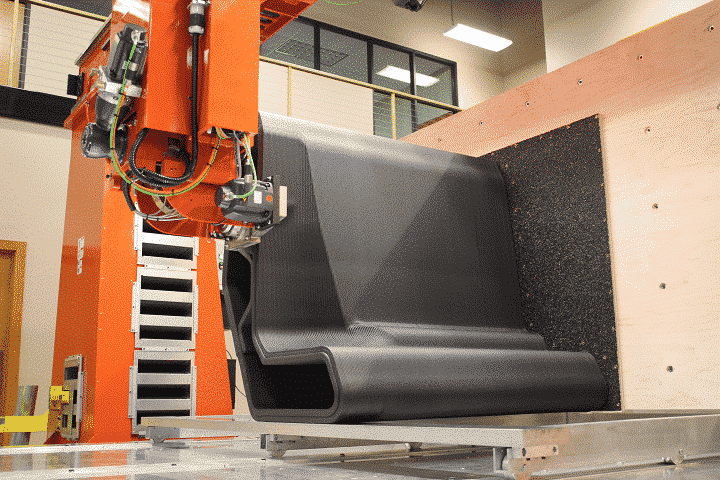

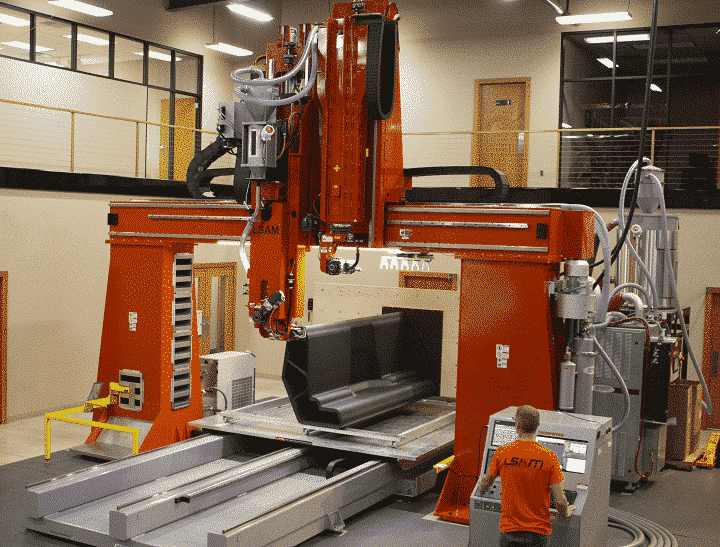

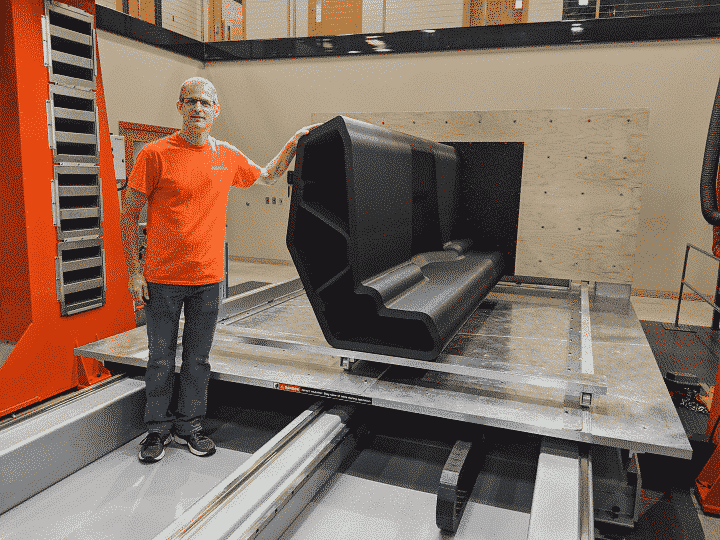

Thermwood Corporation, headquartered in Indiana, is the oldest manufacturer of highly flexible 3-axis and 5-axis CNC routers, and entered the 3D printing industry with a unique hybrid machine five years ago. Since then, it has introduced and continuously improved its Large Scale Additive Manufacturing (LSAM) system. These machines have 3D printing and trimming capabilities, and are obviously used to make very large parts, such as thermoplastic composite molds and tools, suitable for various industries such as aerospace, automotive, defense, government, ships, and the military. Using the company’s patented vertical layer printing (VLP) technology, users can stand more than 20 feet tall and weigh up to 50,000 pounds of 3D printed parts on Thermwood’s large LSAM machine.

VLP can print on a vertical surface instead of a horizontal surface, so it can produce higher parts than printed products with horizontal layers. But now, Thermwood announced that it has successfully demonstrated a new method of using this technology for large-format 3D printing.

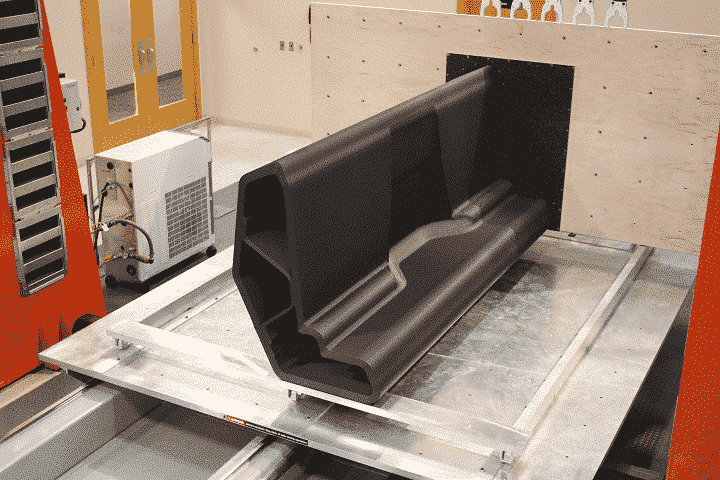

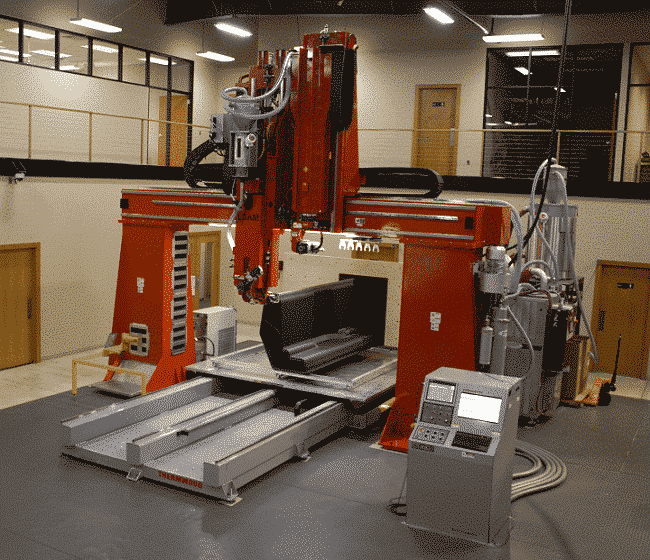

Movable door frame, high wall, and fixed workbench are the typical features of the Thermwood LSAM 3D printing system. When vertical printing is required at a high place, a vertical movable workbench can be used. The workbench is made of immovable stainless steel. The top of the main fixed table. However, Thermwood released MT last year, which is a lower-priced LSAM printer with a movable workbench and a fixed rack, but it can be trimmed on the same machine. Just like the larger LSAM system, parts are quickly printed in 3D and then processed into the final shape and size after cooling.

In order to achieve vertical 3D printing of tall parts on LSAM-MT, the machine will require what the company calls a “fundamentally different approach” in the press release.

Thermwood’s new VLP method prints parts on a support structure that moves along the mobile station but is fixed on the back. On the back of the main table, there is a second 5’x 10′ vertical printing table. As the parts get bigger, move the table to pull it onto the supporting structure. This process allows the LSAM-MT 3D printer to manufacture parts up to 5’x 10’x 10′ (ZXY axis). It reminds me of larger versions of conveyor belt 3D printers, although as far as I know they allow longer parts, they cannot ensure vertical 3D printing.