Often called printer banks or virtual printer networks, cloud printing technology allows for printing through cloud connection rather than traditionally connecting to a PC or print driver. 3D printers can simply register with a cloud print provider and receive print jobs sent from mobile devices, desktops and laptops, or tablets. Users can create innovative designs, load it to the cloud and place an order for 3D print production. The cloud connected printer on the other end responds by printing, packaging, and shipping the order.

This process has resulted in smarter and leaner manufacturing practices by reducing manufacturing costs and inventory expenses and breaking down barriers to entry. Many small manufacturers see this as a good opportunity to bring their innovations to market.

Currently, large manufacturing companies rely on centralized manufacturing hubs that create similar products on a massive scale. 3D cloud printing however, enables diverse products to be created on a much more granular level and does not require a large capital outlay.[i] 3D cloud printing can open doors for small businesses and create a marketplace where businesses of all sizes have access to equal production capabilities.

Further development and integration of 3D cloud printing technology could potentially revolutionize manufacturing. Innovators in the industry are working towards making the technology faster and more versatile. Recent developments include 3D printers up to 500 times faster than current models. Siemens predicts that 3D printing will become 50% cheaper and up to 400% faster in the next five years.[ii] Research and development tax credits are available for both large and small companies working on 3D cloud printer developments and/or integration into their manufacturing process.

The Research & Development Tax Credit

Enacted in 1981, the Federal Research and Development (R&D) Tax Credit allows a credit of up to 13 percent of eligible spending for new and improved products and processes. Qualified research must meet the following four criteria:

- New or improved products, processes, or software

- Technological in nature

- Elimination of uncertainty

- Process of experimentation

Eligible costs include employee wages, cost of supplies, cost of testing, contract research expenses, and costs associated with developing a patent. On December 19, 2014 President Obama signed the bill extending the R&D Tax Credit for the 2014 tax year. As of this writing proposed tax extender legislation would extend the tax credit through December 31, 2016.

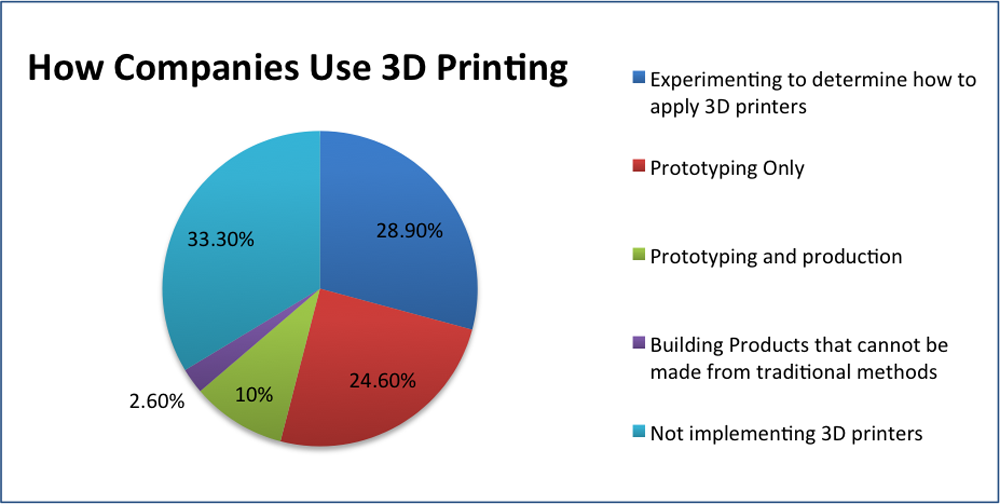

Manufacturers around the country are widely using 3D printers in some capacity. A recent PwC survey revealed that two-thirds of the top 100 U.S. manufacturers are using 3D printing; mostly for experimentation purposes, however many manufacturers use 3D printing for rapid prototyping and some use it for production or custom parts.

The chart below illustrates the how companies have implemented 3D printing technology.[iii]

The data represented in the chart above demonstrates that commercial 3D printing usage is still relatively limited to experimentation and prototyping purposes. However, as the technology becomes faster and more versatile, manufacturers will increasingly start turning to additive manufacturing for more of their regular production needs.[iv] According to Wohlers Associates, a leading firm that studies 3D printing technology and trends, “the production of parts for final products is expected to far surpass prototyping applications for 3D-printed parts”.[v]

This could present a huge opportunity for small companies trying to get into manufacturing. Although high-end, commercial 3D printers are meaningful investments for most small companies, cloud based services such as Shapeways, Cubify, i.Materialise, and Sculpteo offer 3D printing capabilities. Start-ups can now create products without having to make investments in added production equipment. Other benefits include the unprecedented level of customization available with 3D printing. Also, by using the additive manufacturing 3D process versus the traditional “subtractive manufacturing” process, waste materials drop from 90% to between 5% and 10%.

In addition to printing capabilities, cloud based printing companies offer a range of other services including packaging, shipping, copyright protection and even product promotion. Shapeways, based in New York, inspects products and designs received for 3D printing and works with the end user to determine the best parameters for 3D printability.

Cloud capabilities also provides business owners the ability to place orders, manage printers, and tweak designs from anywhere in the world. Employees can use whatever device they have on hand without worrying about software drivers. This translates into reduced support, more convenience, and lower operating costs.

What’s more is that businesses save not only on foregone printer costs but also on software that requires installation and continuous upgrades and maintenance. Cloud software upgrades are automatic and in real time so cloud users will always be up-to-date with the latest features and upgrades.

The added simplicity that comes with the user friendly cloud interfaces is another benefit. For non-technical users, the lack of software, drivers, and cables, is considerably more appealing than traditional printing methods. Cloud solutions are not only easier to use, but faster as well. Anton Vedesin, CTO at 3DPrinterOS stated, “The user benefits are enormous in terms of agility, speed and cost. While current desktop 3D printing software is slow and cumbersome, our cloud-based solution cuts the time to slice a 3D file from 15 minutes to 15 seconds“.[vi]

Conclusion

Cloud printing has the potential to completely revolutionize manufacturing for businesses of all sizes. Companies often exercise caution when considering the large capital outlays associated with quality, commercial 3D printers. With the convergence of 3D printing and cloud computing however, they may be able to enter the market by utilizing 3D printing companies to leverage their production and cloud infrastructure capabilities. Businesses utilizing 3D cloud printing, 3D printing cloud service providers, and 3D printer manufacturers are likely eligible for federal and state R&D tax credits to help support and stimulate these innovation efforts.

[i] “The R&D Tax Credits and the U.S. Initiative” Gary Savell, Andressa Bonafe and Charles G. Goulding, RDTS Publishing, Available online at: https://www.rdtaxsavers.com/articles/US-3D-Printing-Initiative [ii] “2015 Roundup of Market Forecasts and Estimates” Louis Columbus, Forbes Magazine, Available online at: https://www.forbes.com/sites/louiscolumbus/2015/03/31/2015-roundup-of-3d-printing-market-forecasts-and-estimates/ [iii] Two-thirds of industrial manufacturers use 3D printing” Lucas Mearian, Computer world, Oct 9, 2014, Available online at: https://www.computerworld.com/article/2824142/two-thirds-of-industrial-manufacturers-use-3d-printing.html [iv] The R&D Tax Credit Aspects of End Users” BY R&D TAXSAVERS ON MON, JUNE 1, 2015 · 3D PRINTING, BUSINESS,GUEST AUTHOR, INDUSTRY INSIGHTS, RESEARCH, Available at: https://3dprintingindustry.com/2015/06/01/the-rd-tax-credit-aspects-of-3d-printing-end-users/ [v] Stock Bubble? $10.8 Billion By 2021, TJ MCCue, Forbes Magazine, Available online at: https://www.forbes.com/sites/tjmccue/2013/12/30/3d-printing-stock-bubble-10-8-billion-by-2021/ [vi] “3DPrinterOS Launches World’s First Cloud-based Operating System”, PRNewswire, March 18, 2015. Available at: https://www.prnewswire.com/news-releases/3dprinteros-launches-worlds-first-cloud-based-3d-printing-operating-system-300052211.html

Leave A Comment