Ford using in-house 3D printing to make parts for personal protective equipment AM Industry

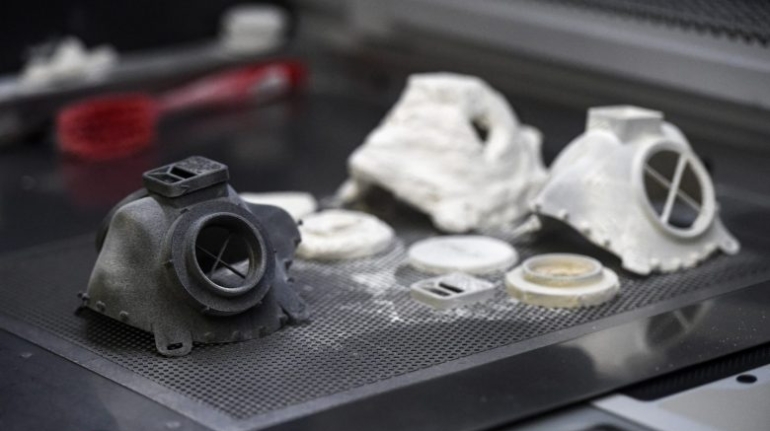

The Ford Motor Company today announced its strategy to support the fight against the COVID-19 pandemic. As part of the plan, it is partnering with 3M and GE Healthcare to help scale up production capabilities for medical equipment and necessary supplies using its expansive manufacturing capacity. The automotive leader is also leveraging its in-house 3D printing capability to produce components for personal protective equipment, and plans to assemble over 100,000 face shields per week.