The Research Institutes of Sweden (RISE), a state-owned institution that works alongside partners in industry, academia and the public sector, has a number of innovative projects under its belt, including an initiative to explore the use of recycled water for irrigation, and an exploration of certifying AI models. The organization is also very active in the area of additive manufacturing research, often exploring the use of the technology to meet sustainability goals. This is very much the case in RISE’s ongoing E3D project, which is exploring the integration of 3D printed concrete into building façades to improve efficiency and sustainability in the Swedish construction industry.

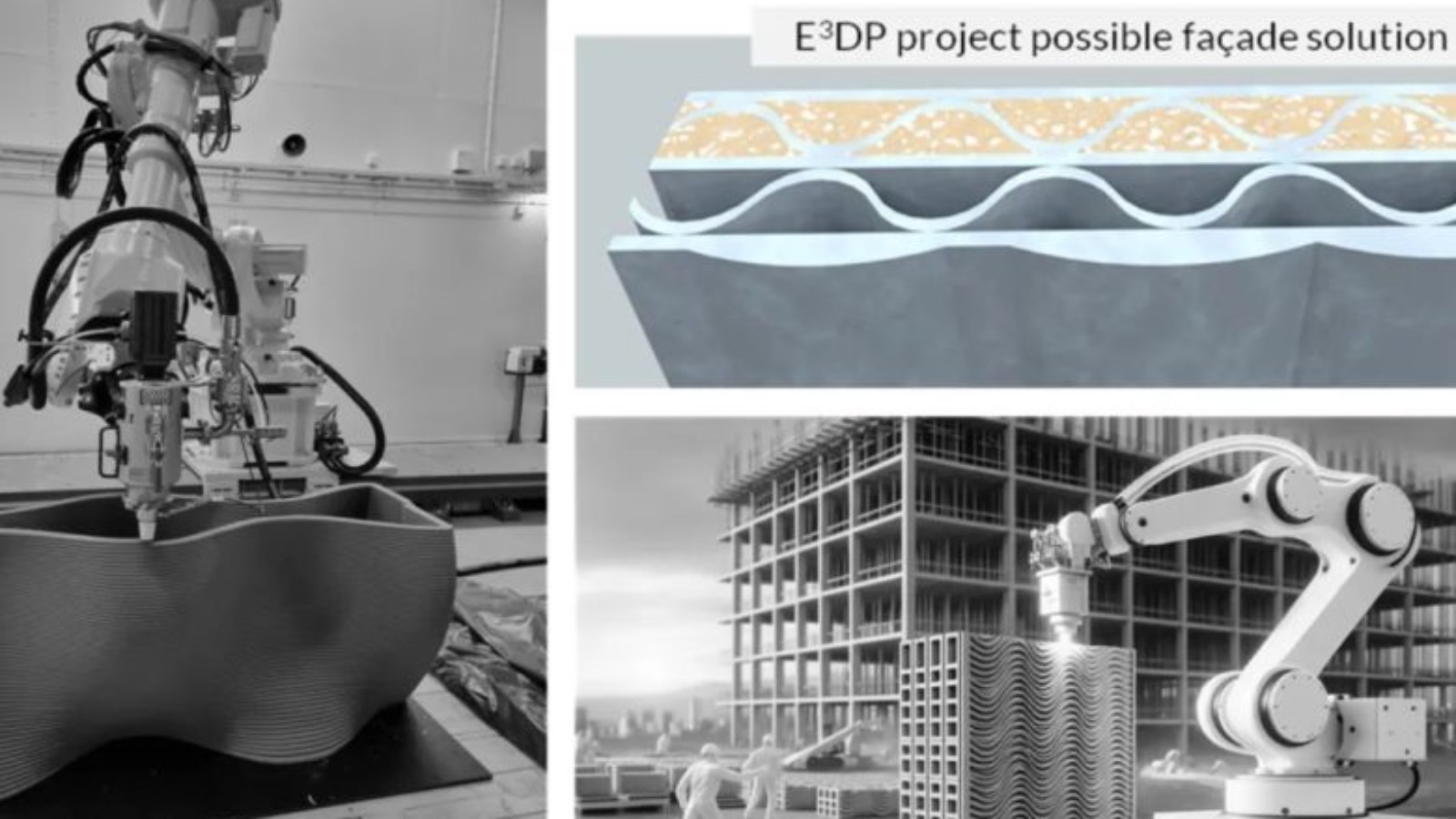

As RISE explains, the E3D project’s main goal is to improve the energy efficiency of buildings through the use of 3D printed concrete. This will be pursued in many ways, including by reducing material use and construction time by using 3D printing to construct the concrete elements, as well as through eco-driven design. “The E3D project is dedicated to enhancing energy efficiency of building facades through the innovative use of 3D printed concrete elements,” the Swedish research institute says. “By incorporating 3D printing technology with sustainable construction practices, E3D aims to address the limitations of traditional facades and contribute to a more resource-efficient and environmentally friendly building industry.”

Manufacturing on Demand

RISE emphasizes the importance of 3D printing technologies in realizing more sustainable building practices and design. The technology opens up opportunities for greater design flexibility and customization, while simultaneously reducing material consumption and labor associated with more traditional construction. In the project, robotic 3D printing will be used to produce “passive façade elements”, which enhance the building’s energy consumption and address the potentially damaging effects of climate variation and moisture. Passive design is becoming increasingly common in architecture and construction, as it aims to minimize a building’s energy consumption and improve comfort through design elements like orientation, sunscreens, insulating materials and more.

In this case, passive design elements will be integrated with active façade solutions to “change the building envelope’s role in energy efficiency”. According to RISE, this will involve the use of an innovative insulating material made from cellular lightweight concrete (CLC), which offers greater durability and insulation properties. The E3D project is also based on a user-centric approach. In other words, RISE has consulted with market players and stakeholders as well as conducted life cycle assessments to ensure that the project’s goals are in line with real-world needs and requirements.

The project, which kicked off earlier this month in Sweden’s Västra Götaland region, is being funded by Energimyndigheten, the Swedish Energy Agency and will reportedly run for three years. Watch this space for updates on the E3D project as it progresses.

You might also like:

Qorox creates world’s largest 3D printed skateable sculpture: The adoption of 3D concrete printing is expanding worldwide, with applications extending beyond affordable housing to include artificial reefs, street furniture, infrastructure, and art. Destination Skatepark now consists of a variety of 3D printed features, such as quarterpipes, ledges, and supports, all created by QOROX. The park’s highlight is ‘The Wave’, a 12-meter-long, 3-meter-high skateable sculpture that mimics curling water. Comprising seven different elements, this sculpture was printed in under five hours and is recognized as the largest 3D printed skate sculpture globally.

* This article is reprinted from 3D Printing Media Network. If you are involved in infringement, please contact us to delete it.

Author: Tess Boissonneault

Leave A Comment