International researchers at the Swiss Federal Laboratory for Materials Science and Technology (EMPA) led by Shanyu Zhao, Gilberto Siqueira, Wim Malfat, and Matthias Korbel are exploring a new method of additive manufacturing of aerogels on a microscale, and detailing their study in the recently published “Additive manufacturing of silica aerogels.” At present, in various applications requiring thermal conductivity, silica aerogels can be used in the fields of optics, particle capture, physics, and so on. However, most commonly, these materials are used for thermal insulation, especially in confined spaces that may require cushioning.

Historically, silica aerogels have been considered difficult to handle due to their fragility (which usually results in the need for additives and may even be further restricted in terms of miniaturization), which has led researchers to develop a new kind of the patented technology uses direct ink writing (DIW) to form microstructures.

Using silica aerogel powder slurry, the author reported improved methods such as shear thinning, improved fluidity and higher viscosity after printing, so that 3D printed objects made of pure silica are more stable. The overall goal of the researchers is to refine the aerogel so that it can be used better at a smaller size-here, the size is only a tenth of a millimeter.

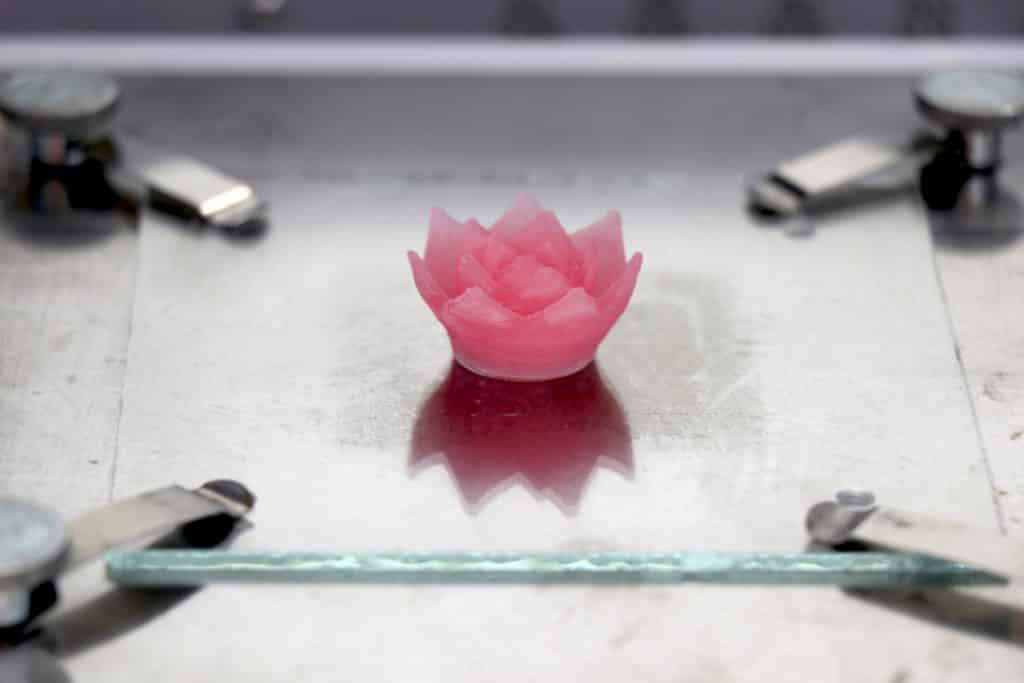

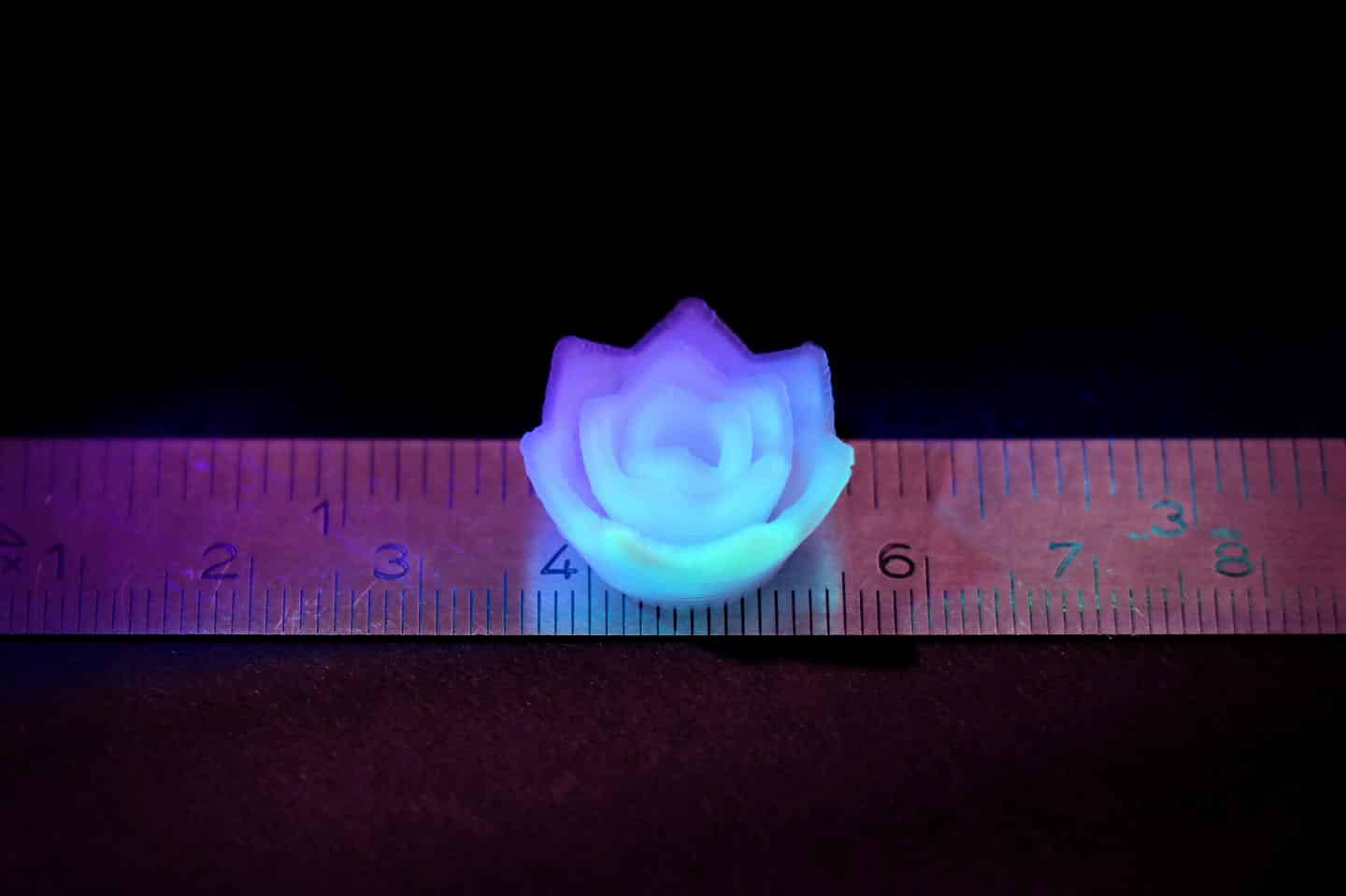

The thermal conductivity of silica aerogel is not high, but these materials have good mechanical properties. The author reports that the 3D printed aerogel can be “drilled and ground”, leaving the potential for post-processing of molded parts. During the research process, 3D printed samples were made in the form of leaves and lotus flowers, which not only showed the ability to design overhanging structures, but also demonstrated the ability to print complex geometric shapes using multiple materials. Due to their small size, these materials can also be used for thermal insulation of electronic devices, preventing them from interacting with each other when they are in close proximity, and effectively controlling conductive hot spots.

The researchers also made a hot water molecular air pump (or Knudsen pump) from aerogel materials, reinforced with black manganese oxide nanoparticles on one side. After exposure to light, the material heats up on the darker side and pumps gas or releases solvent vapor.

This advancement also provides the potential for the use of aerosols in medical implants, which can protect human tissues from heat above 37 degrees. Currently, EMPA researchers are looking for partners who are interested in using new 3D printed aerogels for industrial applications. Also check some of their previous research, as they have developed other types of 3D printing inks made of cellulose, as well as unique molds for sensor development.