While big corporations have been using the technology for R&D purposes for some time, since last year, large companies that dominate the larger economy have been strategically getting into the 3D printing space in a big way. Some have jumped in, intent on conquering the industry as a whole, including: Autodesk, HP, and GE. Others are making small moves, likely working on a larger strategy, like Wal-Mart, Ford, and, now Siemens. Earlier this year, the multinational announced that they would be adding a number of 3D printing startups to their Frontier Partners Program, providing these firms with software and guidance. Today, the company announced an investment, via the Venture Capital Unit of Siemens (SVC), in Materials Solutions Limited, a UK firm devoted to metal 3D printing, with a plan to incorporate their technology into their gas turbine manufacturing process.

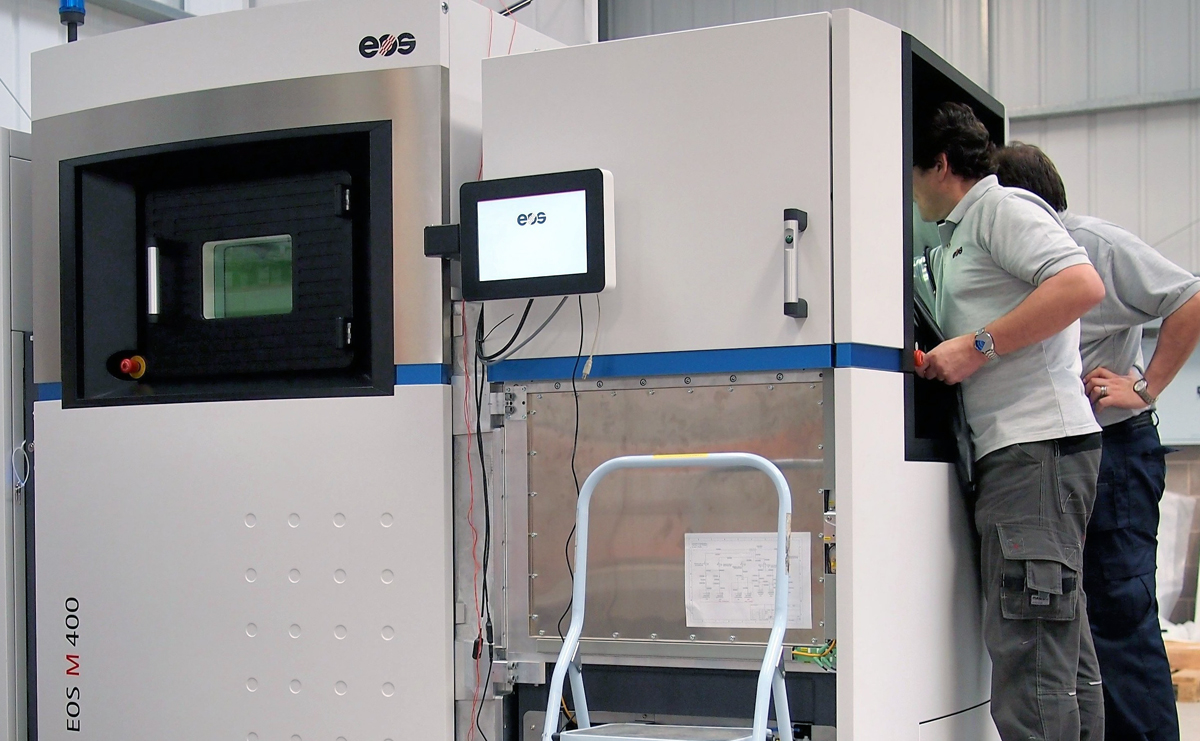

Materials Solutions is both a developer of high performance materials and laser 3D printing processes. With a suite of EOS laser sintering machines, the firm performs engineering and 3D printing services with high temperature alloys, including iconel, cobalt, titanium, stainless steel, and more. Materials Solutions focuses primarily on aerospace and the energy sector and has had some pretty huge clients, including just about every division of Rolls-Royce, including their Nuclear division, as well as ITP, Sumitomo Precision Products, and an unnamed sports car manufacturer. It’s these qualifications that drove Siemens to invest in the company.

Founder and CEO of Materials Solutions, Carl Brancher, said of the news, “I am extremely pleased that SVC has chosen to invest in Materials Solutions. I believe this investment validates Materials Solutions as the global technology leader in Additive Manufacturing of nickel superalloys.” He added, “Since starting up in 2006, Materials Solutions has developed high performance materials and manufacturing processes for laser powder bed Additive Manufacturing particularly targeting gas turbine applications. Our capabilities in Additive Manufacturing reduce development time and improve new product performance for our customers.”

Ralf Schnell, CEO of the Venture Capital Unit of Siemens, elaborated on Siemens’ reasons for investment. “There are now strong signs that Additive Manufacturing will move into mainstream production for land and aero gas turbine components. Materials Solutions are outstanding in capability and experience and we will support their expansion.” He continued, “My team and I are very excited about the huge benefit for Siemens’ Additive Manufacturing Industrialization Strategy resulting from this strategic collaboration”, said Andreas Fischer-Ludwig, Director Manufacturing Development & Industrialization, for Siemens Large Gas Turbines, Generators Business Unit.”

Markus Seibold, head of Enabling Manufacturing Technologies at Siemens Large Gas Turbines, Generators Business Unit, implied that Siemens would be relying on the technology for the production of parts for their gas turbines, “We know the people at Materials Solutions well and they provide strong support for the introduction of Additive Manufacturing into our large gas turbines and distributed power generation products.”

Siemens’ investment in the company, though the dollar amount has not been disclosed, suggests that 3D printing could bring significant advantages to their Gas Turbines division. Meanwhile, GE has already begun implementing the technology in their own gas division. The optimization of parts could save costs for both multinationals, in the long run, as complex designs with multiple components can be streamlined into individual parts manufactured at once.

Leave A Comment