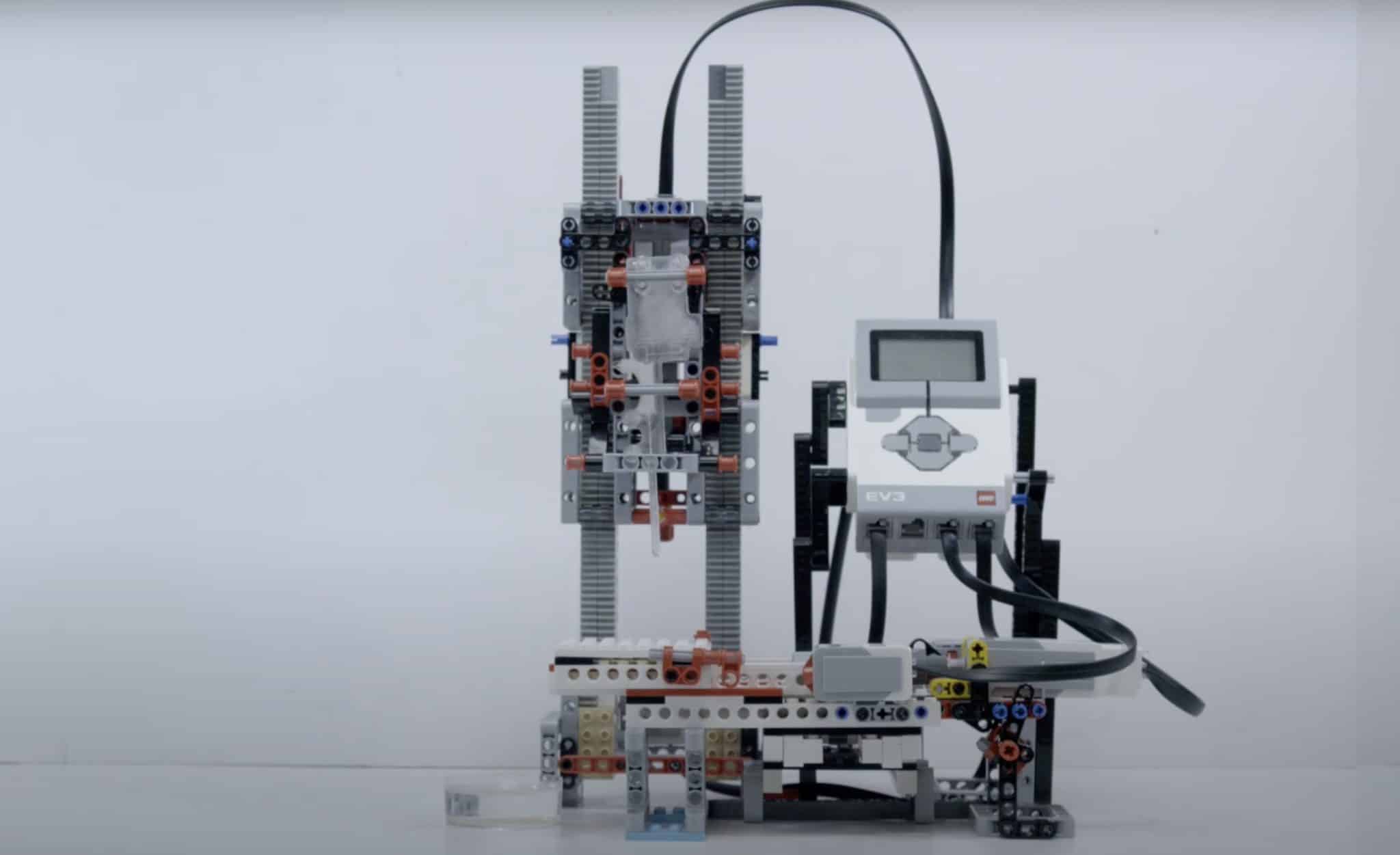

Scientists at Cardiff University’s School of Pharmacy and Pharmaceutical Sciences have designed and built a fully-functional 3D printer out of LEGO that can print synthetic skin and other tissues. The LEGO bioprinter is more affordable than other similar systems on the market and is open for anyone to replicate.

Using LEGO Mindstorm kits and a programmable controller, they have designed an inexpensive and easy-to-build 3D printer that is contributing to pioneering research. The team at Cardiff (Dr. Chris Taylor, Dr. Sion Coulman, Dr. Oliver Castell, and Dr. Ahmed Moukachar) are using the LEGO bioprinter to create 3D models of synthetic skin to be able to test drug delivery and efficacy.

Manufacturing on Demand

The researchers have published the design for the printer so that researchers across the globe can build their own. This work was primarily supported by a British Skin Foundation (BSF) Ph.D. studentship grant (059/s/16), together with support from the European Union’s Horizon 2020 research and innovation program under grant agreement ID: 824060 – ‘ACDC’. Music.

Like conventional extrusion 3D printers, the prices of microfluidic-based bioprinters have dropped dramatically since the first RepRap and open-source systems were released on the market. Using LEGO can potentially make them even more affordable. LEGO is not directly involved in this project however the Danish company has been rapidly increasing its interests and activities in additive manufacturing in recent months and this initiative could offer an opportunity for a new line of products.

You might also like:

KAM acquires Velo3D Sapphire XC printer: KAM’s Sapphire XC printer is calibrated to print in a nickel-based superalloy that delivers oxidation and corrosion resistance at high temperatures. The alloy is commonly used in aviation, space, defense, and energy applications – all of which are key industries for KAM. The company purchased the Sapphire XC to enable the printing of significantly larger parts.

* This article is reprinted from 3D Printing Media Network. If you are involved in infringement, please contact us to delete it.

Author: Davide Sher

Leave A Comment