Researchers from the University of Wollongong (UOW) ARC Centre of Excellence for Electromaterials Science (ACES) in Australia, have developed a customizable 3D bioprinter, 3D Alek, to combat congenital ear deformity.

Designed for the treatment of microtia, the 3D Alek has been installed at the Royal Prince Alfred Hospital (RPA) in Sydney.

“Treatment of this particular ear deformity is demanding because the outer ear is an extremely complex 3D shape, not only in length and breadth but also in height and projection from the skull,” explained Payal Mukherjee, Clinical Associate Professor at the RPA Institute of Academic Surgery (IAS).

“This is where bioprinting is an extremely exciting avenue, as it allows an ear graft to be designed and customized to the patient’s own face using the patient’s own natural tissue – resulting in reduced operating time and improved cosmetic outcome – and avoids the current complication of requiring a donor site for cartilage, usually from the patient’s rib cage.”

3D printed ears

As a genetic condition, microtia affects children and can cause hearing loss. According to Australian charity FutureHear, the disorder “occurs in 1 in 6,000 births world wide” and, as such, there are a number of institutions across the nation are turning to 3D printing to help.

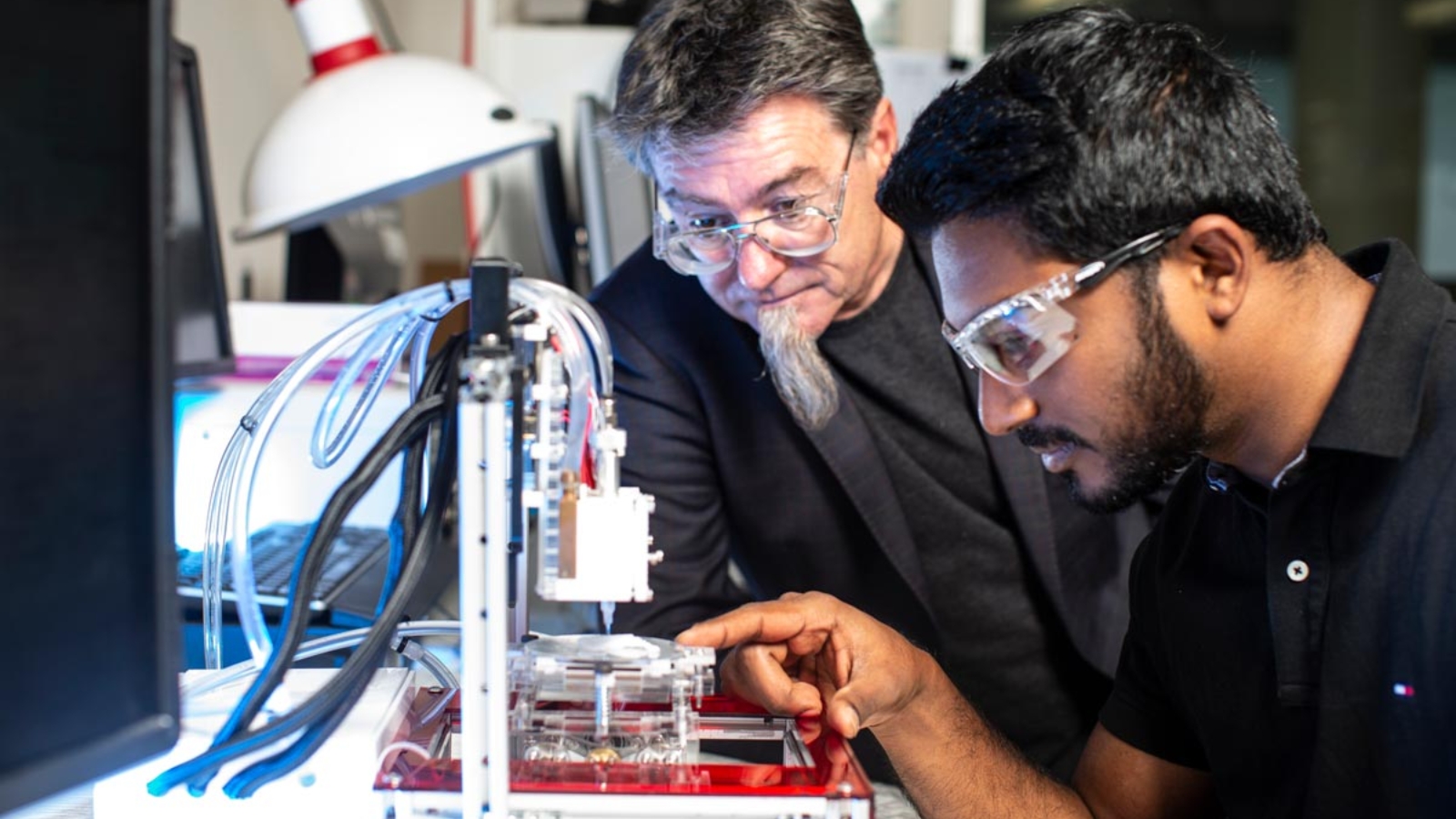

Researchers from UOW and ACES, as well as the Australian National Fabrication Facility (ANFF) created the 3D Alek to make structures using stem cells-containing bioinks, that would aid in cartilage regeneration. Professor Gordon Wallace, Director of ACES, explains, “We have been responsible for the primary sourcing of materials; the formulation of bio-inks and the design and fabrication of a customized printer; the design of required optimal protocols for cell biology; through to the final clinical application.”

Manufacturing on Demand

“With one 3D Alek now established in a clinical environment at RPA and a replica in our lab at TRICEP, our new 3D bioprinting initiative, we will be able to fast-track the next stages of our research to deliver a practical solution to solve this clinical challenge.”

Pioneering 3D Bioprinting

In addition to TRICEP, Professor Wallace has worked in a number of other notable 3D bioprinting projects. Through ACES and UOW, the University of Sydney’s Save Sight Institute was awarded $1.15 million for the commercial development of its cornea-correcting iFix Pen, last year.

Prior to this, the UOW Intelligent Polymer Research Institute (IPRI), also directed and founded by Professor Wallace, has been using 3D bioprinting to reproduce brain cells, in a project studying conditions such as schizophrenia, epilepsy, and depression.

Having proved 3D Alek in a clinical environment, the next step of UOW and ACES research is to pursue clinical trials, and to develop the ability to work with a patient’s own stem cells.

* This article is reprinted from 3D Printing Industry. If you are involved in infringement, please contact us to delete it.

Author: Tia Vialva

Leave A Comment