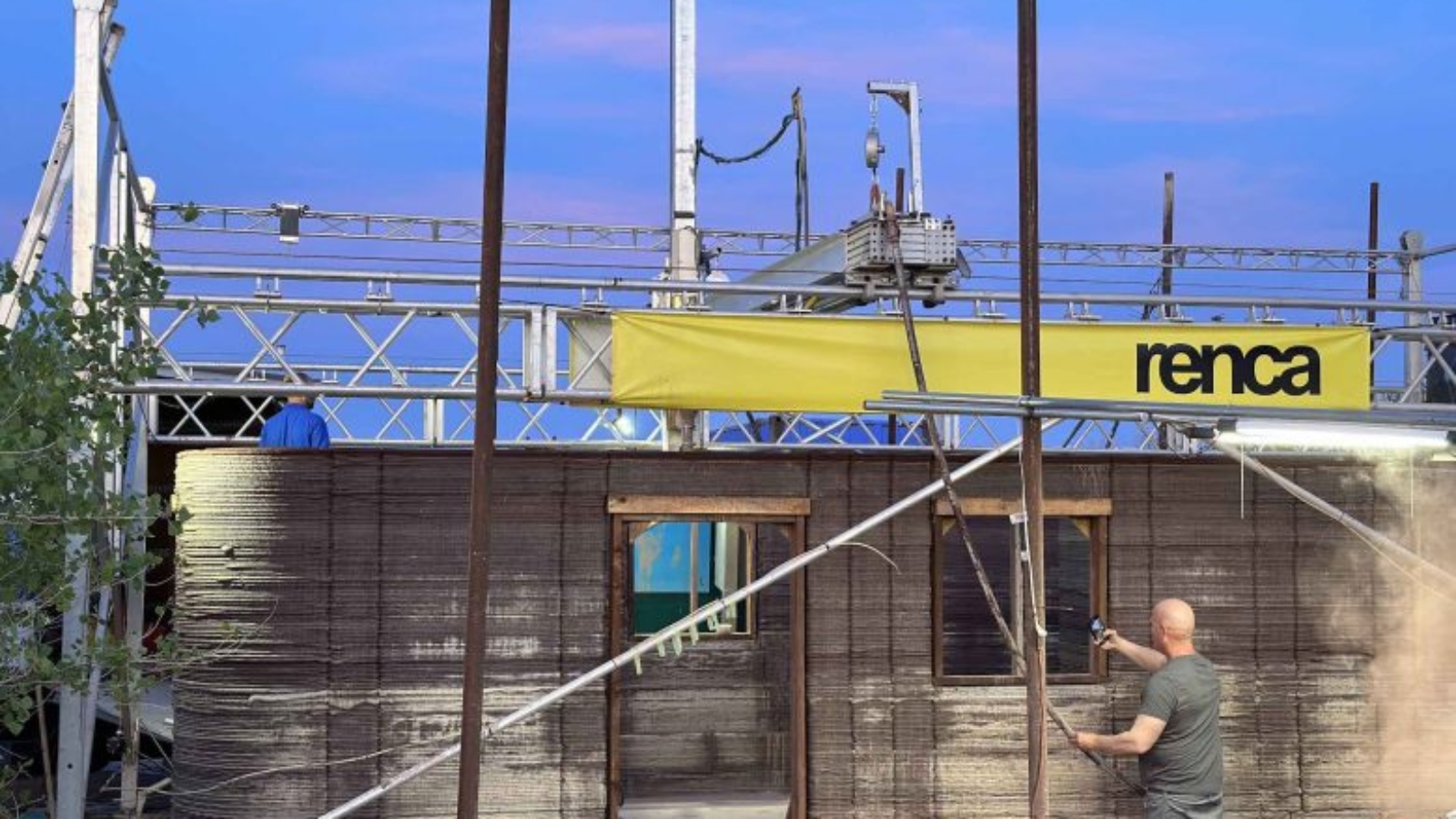

RENCA, a pioneer in sustainable geopolymer materials for construction 3D printing, has set a significant milestone in the construction industry by using their zero-cement geopolymer 3D printing mortar in the construction of the world’s first 3D printed geopolymer house. The sustainability of construction materials and methods is a major global concern, given the significant pollution contributed by these elements. With emerging technologies such as 3D printing, new possibilities for reducing environmental impact are arising. This technology not only offers unparalleled freedom in design but also lessens the waste produced and the materials required.

Until now, a significant contributor to carbon dioxide emissions in the 3D construction sector was Portland cement, an ingredient found in all 3D printing mortars. Geopolymer materials, which contain no Portland cement, lime, or gypsum, are up to 90% more sustainable than typical cement-based alternatives. These materials, which RENCA began working with in 2015, have proven to be not only more sustainable but also more durable, capable of enduring thousands of years compared to a few decades with traditional materials. Over 300 products utilizing these materials have been developed for various uses, effectively minimizing the environmental impact of numerous industries.

Manufacturing on Demand

Apis-Cor, another construction 3D printing company, had its initial experience with RENCA’s geopolymer 3D printing mortar in 2016. Recently, RENCA, in collaboration with Strong Print 3D and Geopolymer International, made history by completing a 3D printed house structure using their geopolymer mortar, despite challenging conditions in the western USA desert.

Despite needing a specific approach towards mixing procedures, the success of RENCA’s geopolymer mortars signifies the dawn of a new era in construction. Current research and development efforts at RENCA are focused on creating a one-component geopolymer mortar for continuous mixers and a two-component system to control the setting time. These advancements will offer even greater flexibility and lessen the dependence on external conditions.

You might also like:

California welcomes first 3D printed home thanks to Emergent: The landmark project – at 1,200 square feet (110 m²) – unveiled in a ribbon-cutting ceremony near Redding’s Reginato Boat Ramp last week, serves as an example of Emergent’s commitment to revolutionizing construction techniques. Using COBOD’s state-of-the-art 3D printing technology, the firm reportedly aims to create homes that are more durable, disaster-resilient, and in tune with the surrounding environment.

* This article is reprinted from 3D Printing Media Network. If you are involved in infringement, please contact us to delete it.

Author: Edward Wakefield

Leave A Comment