Volumetric 3D bioprinter manufacturer and EPFL spin-out Readily3D has taken the first step towards developing a 3D printed living model of the human pancreas for testing diabetes medicines.

Readily3D’s novel technology is being deployed within the EU-funded Enlight project and is reportedly capable of 3D printing a biological tissue containing human stem cells in just 30 seconds.

As the project’s official bioprinter manufacturer, the company has adapted its proprietary contactless tomographic illumination technology to suit the specific needs of pancreatic tissue structures.

“Developing a system that can 3D print tissue at the cubic centimeter-scale and faithfully replicate the functioning of a live pancreas is a huge challenge, which we hope to meet with this technology,” said Christophe Moser, Head of the EPFL’s Laboratory of Applied Photonics Devices (LAPD).

Combating pancreatic disease and diabetes

Located just behind the stomach, the pancreas serves several vital functions, such as producing enzymes and bicarbonates essential for digestion and secreting a variety of hormones. One of these hormones is insulin, which regulates the body’s blood sugar levels. As such, pancreatic disease can often lead to the development of diabetes as the organ’s damaged cells can no longer produce the insulin the body needs.

According to The International Diabetes Federation and the European Diabetes Study Center (CeeD), more than 450 million adults worldwide suffer from diabetes, and this number is continuing to grow. Diabetes is also reportedly the second-leading cause of amputation and significantly increases the risk of a heart attack, stroke, and kidney failure.

The Enlight Project has received €3.6 million in funding from the EU’s Horizon 2020 Framework Program to develop the first living model of the pancreas within the next three years. The project is being carried out by a consortium led by UMC Utrecht and made up of EPFL, ETH Zurich, the University of Naples Federico II, AstraZeneca, Rousselot, Readily3D, and the Giannino Bassetti Foundation.

The overarching aim of the Enlight project is to develop the living pancreas model for the testing of new diabetes medications to improve both diagnosis and treatment of the condition.

3D printing the pancreas

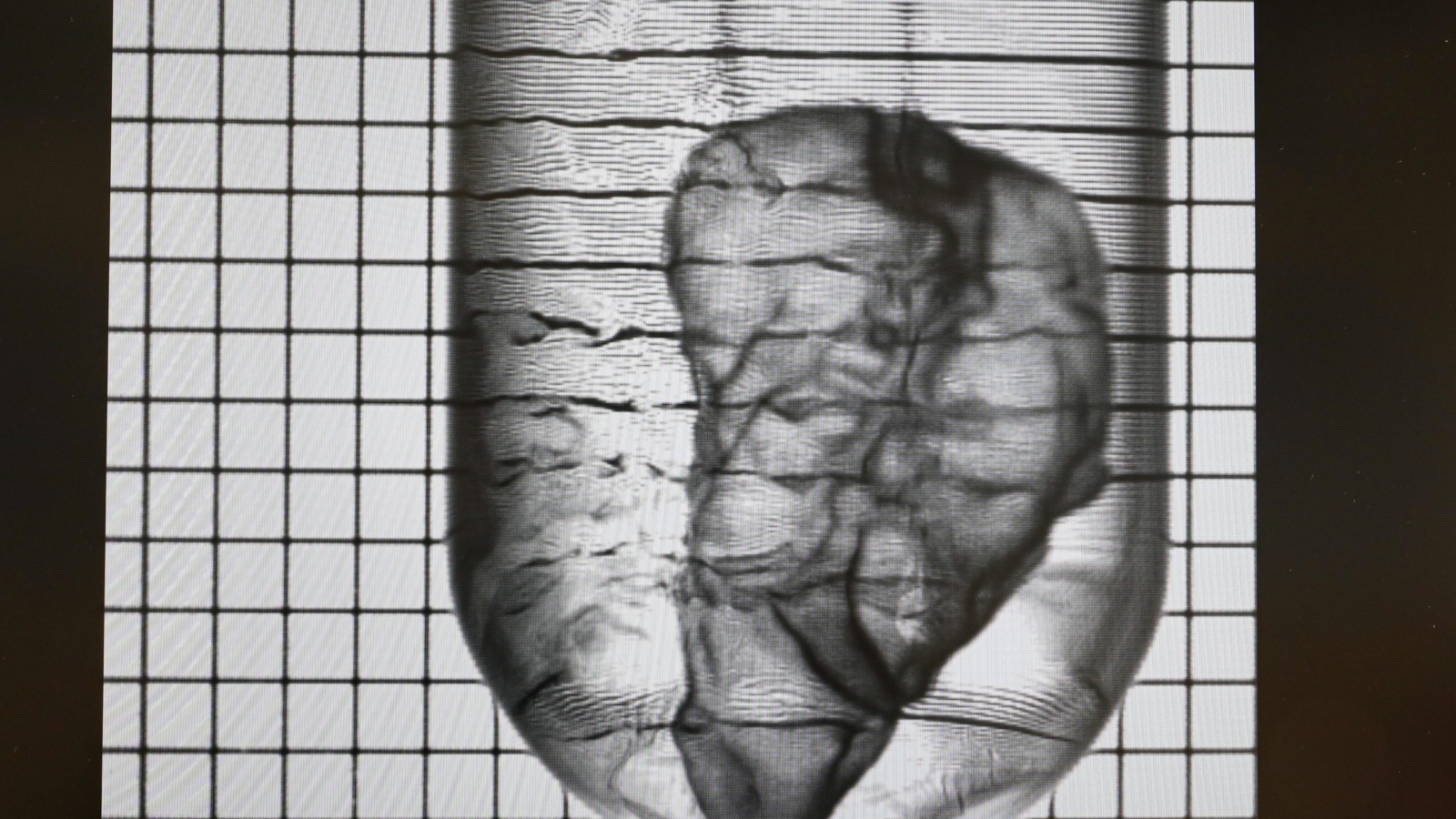

The novel bioprinting technology is based on Readily3D’s existing Tomolite 3D printer, which uses a biological gel containing a patient’s stem cells. A laser is then applied to the gel to solidify it via polymerization, with the location and intensity of the laser beam controlled to solidify only those areas of the gel needed to form the desired tissue.

Manufacturing on Demand

“One of the main advantages of our method is that it can create tissue in a single block, making it particularly useful for printing soft tissue like organs,” said Paul Delrot, CTO of Readily3D.

The bioprinter is reportedly capable of printing the centimeter-scale structure in less than 30 seconds, a significant achievement as the survival rate of living cells decreases drastically as print times increase.

Readily3D’s technology was selected for use within the Enlight Project earlier this year. The technology enables tailor-made structures to be printed as it is created from a patient’s own stem cells, meaning patients will no longer have to try out an array of drugs, some of which can have unpleasant side effects, before finding the right one for them.

According to the consortium, the technology developed during the project could be used to bioprint other kinds of tissue for developing treatments for cancer, or even for producing transplant organs, in the future.

The technology additionally eliminates the need for animal testing, a goal that is also sought by researchers at the University of Stuttgart and Robert Bosch Hospital who have announced the development of a novel 3D printed tissue platform that could replace animal testing within clinical trials of cancer drugs.

In a similar vein, 3D bioprinter manufacturer CELLINK recently acquired in-vitro technology specialist MatTek Corporation to advance its research into animal cruelty-free cellular testing models.

Further work addressing new methods of drug testing for diabetes has been carried out by a team from Pohang University of Science and Technology and Pusan National University. The team 3D printed an in vitro artificial skin model to observe skin diseases suffered by diabetic patients to which test drugs can be applied.

* This article is reprinted from 3D Printing Industry. If you are involved in infringement, please contact us to delete it.

Author: Hayley Everett

Leave A Comment