Rapid manufacturing service bureau Protolabs has added HP‘s Multi Jet Fusion to its range of 3D printing technologies in Europe, following a successful US launch.

Protolabs now offers four industrial 3D printing technologies and can produce plastic, metal, and elastomeric components in as fast as a single day.

Protolabs brings Multi Jet Fusion printing technology on board

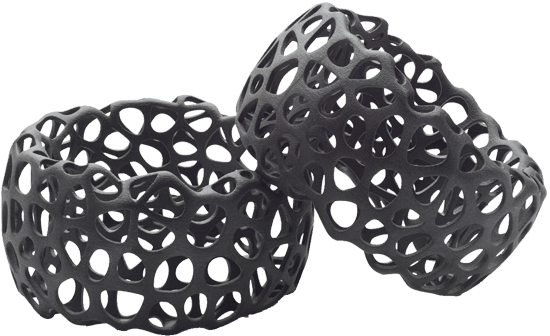

Multi Jet Fusion is a production-grade 3D printing technology developed by HP. It uses an inkjet array to apply fusing and detailing agents across a bed of nylon powder. The powder is then fused into a solid layer with the application of heat.

The process of binding powder results in greater isotropic material properties, faster build speeds, and manufacturing cost savings. Multi Jet Fusion has been applied to functional prototypes, jigs, fixtures, production-ready parts, and components that require high strength or temperature resistance.

“To support our growth trajectory we are expanding our 3D printing service provision to include Multi Jet Fusion,” commented Daniel Cohn, General Manager of Protolabs’ German business. “With the addition of Multi Jet Fusion, we now have 4 advanced 3D printing technologies available for our customers to take advantage of, with different advantages to each.”

Protolabs capitalizes on growth

Protolabs reported record annual revenues for the financial year 2017, turning over $344.5 million. This marked a 15.6% increase on 2016’s end of year revenue which was $298.1 million.

While injection molding and CNC milling are Protolabs’ two largest areas of business, 3D printing saw an annual revenue $43.2 million, a 14.5% growth on the financial year 2016’s revenue of $37.8 million. With double-digit growth figures, Protolabs is capitalizing on the strength of its 3D printing service with the further introduction of Multi Jet Fusion.

Daniel Cohn added:

“We piloted Multi Jet Fusion with our US business in 2017. From this, we can verify the benefits of the technology for producing parts with consistent material properties and improved surface finishes, attributes considered difficult to achieve with powder-based 3D‑printing.”

“With this confidence behind Multi Jet Fusion, we look forward to supporting our European customer’s project requirements using this new technology,” Cohn continued.

The nominations period for the Industry Awards 2018 ends soon, don’t miss the opportunity to tell us who is leading the additive manufacturing industry.

Want to design the trophy for this year’s Industry Awards? Protolabs is sponsoring the 2018 Industry Awards design competition. Submit your design now to win a 3D printer.

For more 3D printing news, subscribe to our free Industry newsletter, follow us on Twitter, and like us on Facebook.

Featured image shows the Protolabs UK facility in Telford, Shropshire. Photo via Protolabs.

Leave A Comment