UAE-based Proto21, one of the most prolific 3D printing service providers in the Middle East and possibly worldwide, just 3D printed 1,008 pieces to form the 32-meter long modular facade of the new adidas flagship store in Dubai Mall.

According to Proto21’s Founder and CEO Pir Arkam (in the center in the photo below), this is the largest 3D printed model ever produced in the Middle East (hard to argue with that, even if we do include 3D printed buildings) and for sure the largest modular 3D printed object. Each of the 1,008 pieces that compose the facade measures 200x200x180 mm and the entire project required 20,160+ hours of continuous printing. This means that a single printer would take over 28 months to complete it.

Manufacturing on Demand

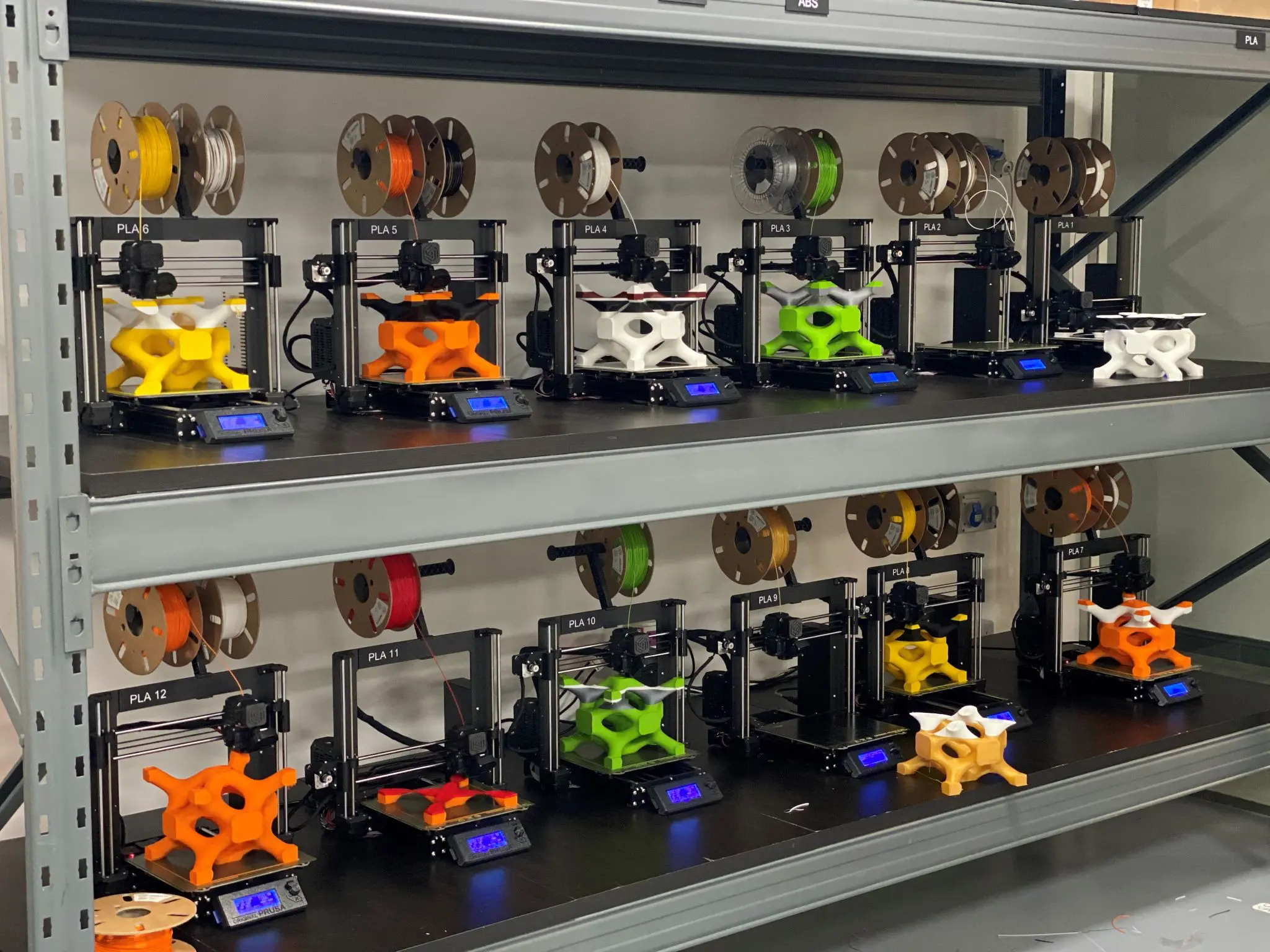

Proto21 houses a 3D printing production facility with multiple Prusa systems that were able to complete the entire project, included the installation, in just 3 months. The total material consumption was 450 Kg of rPLA filament from Filamentive.

Arkam also emphasized that 3D printing was the ideal production method even for such a large number of components since it only required 2016 kWh of energy. In addition, the geometry of each module would be at least challenging to replicate by injection molding. The result is quite spectacular and befitting a footwear company such as adidas that has contributed to make 3D printing into a real mass production method for midsoles.

* This article is reprinted from 3D Printing Media Network. If you are involved in infringement, please contact us to delete it.

Author: Davide Sher

Leave A Comment