Egyptian researchers Passent Aly and Cherif Mohsen compared the advantages of 3D printing with traditional techniques in the production of denture castings, and published their “Comparison of Accuracy of 3D Printed Castings, Digital Molds, and Conventional Castings: In Vitro Research.”

In terms of the oral cavity and jaw repair, prostheses are critical to the health of many patients. In this study, Aly and Mohsen matched traditional stone castings with 3D prosthetic castings printed using stereolithography (SLA) and “digital castings” (that is, 3D scans of existing stone castings). Although digital technology is becoming more and more popular in projects such as casts (using 3D printing instead of traditional methods for prototyping and creating functional parts), the authors point out that for clinical practice, a large number of such processes must first be evaluated.

In testing the effectiveness of the digital mold in this study, Aly and Mohsen used a lightweight desktop scanner to prototype. To compare the experiments, the researchers used a set of upper and lower jaw ivory. Five stone castings were made with a polyvinylsiloxane impression.

“The typodont casts (reference casts) were scanned using intraoral dental scanner (Trios 3Shape) in the following three steps: first maxillary and mandibular casts were scanned separately; the second step involved articulating the maxillary and mandibular arches by utilizing the ‘bite registration algorithm.’ Third and finally, digital casts (n = 5) were exported in STL file format to be integrated into space analysis software,” explained the researchers.

Then use VisiJet SL Clear resin to print the digital mold on the ProJet 6000.

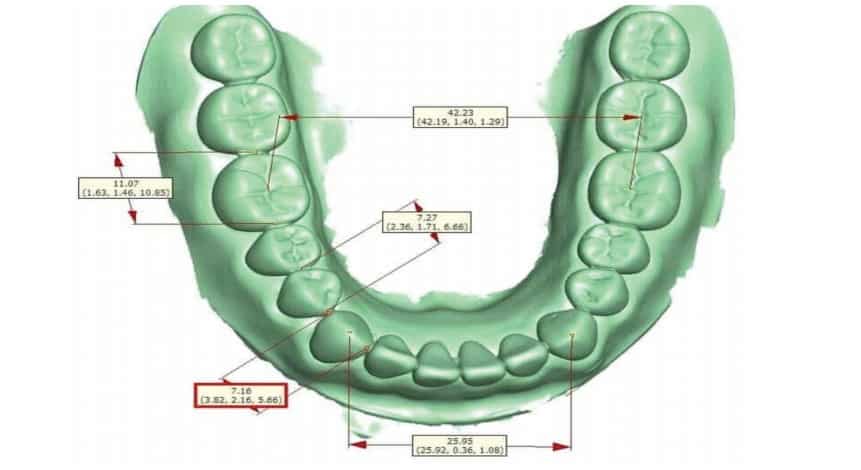

“The following linear measurements were taken: mesiodistal (MD) and occlusocervical (OC) for first molar, first premolar and canine in addition to intermolar width (IMW) and intercanine width (ICW) on both arches and sides by the same operator,” stated the researchers.

The errors that occurred are as follows:

“The errors ranged from 0.003 to 0.142 mm for different measurements. In OC, the errors of digital cast were significantly higher than the errors of the other two groups, where the mean of the digital cast = 0.016 compared with 0.004 and 0.007 for the other two groups (p < 0.0001). Similarly, in MD measurements, the error of digital casts (mean = 0.006) was significantly greater than the error of printed casts (mean = 0.003) but similar to those of conventional casts (mean = 0.005) with overall significant difference (p = 0.02). For IMW and ICW, digital casts had significantly greater errors (mean = 0.142 in IMW and 0.113 in ICW) compared with the two other groups (means= 0.019 and 0.008 in IMW and mean = 0.021 and 0.011 in ICW), p < 0.0001.”

Overall, compared to stone castings, only “small errors” were found in the accuracy of 3D printed castings. The author can confirm the advantages of using SLA printing in this field. However, they did notice a “significant difference” in accuracy between the SLA cast and the digital cast:

“The cause of this error in the arch width measurements is due to the overestimation of digital measurements in comparison to stone and printed casts. Also, distortion of arch happens during scanning of dental casts,” concluded the authors. “But this error is still within the acceptable clinical range which comes in agreement with other studies.”

“This study used only one type of intraoral scanners and one type of 3D printers. Also, it is an in vitro study not simulating the conditions in the oral cavity, such as saliva, bleeding, limited mouth openings, and difficulty in vision, which are considered limitations of the current study. Thus, further studies are needed to evaluate the accuracy of other scanners and printers in comparison with the types used in this study. In addition, there is a need for future in vivo studies simulating oral conditions.”

3D printing of dentures and implants continues to change the quality of life of people in need around the world, be it dentistry, orthodontics, or even limb replacement.