Researchers from the Pohang University of Science and Technology (POSTECH) have developed 3D printed stents that could ease the symptoms of esophagitis in radiotherapy patients.

Based on a throat cell-derived bio-ink, the team’s dumbbell-like devices proved capable of reducing the inflammation caused by radioactive cancer therapies. The scientists believe that their potential esophagitis cure could also be loaded with other tissue-specific cells, and used to treat local injuries such as wounds or burns in the future.

“The effectiveness of [radiotherapy] treatment is negated if proper nutrition cannot be delivered due to the pain,” explained Dong-Woo Cho who led the study. “If this esophageal stent implantation is applied clinically, we expect that the patients will have better prognosis and higher quality of life.”

Treating the side effects of chemotherapy

Although radiation therapy can often be a lifesaving treatment for cancer sufferers, it frequently causes them to experience other unpleasant symptoms as well. Radiation esophagitis is a particularly nasty after-effect of the therapy, that leads to throat pain and inflammation in patients, and in the most acute cases, even death.

According to the Radiation Therapy Oncology Group (RTOG), the condition also causes 25 percent of patients to suffer from eating disorders, prolonging their recovery. Despite this, no cure currently exists for radiation esophagitis, and therapies such as antibiotic and nutritional support often require oral dosage, which has limited their success.

While stents are sometimes used to treat esophageal diseases, they can cause recurrent dysphagia, and don’t directly treat inflammation. To combat these adverse effects, the scientists theorized that a hydrogel could be loaded into a biodegradable stent, serving to treat patients without causing further discomfort.

3D printing a radiation-fighting stent

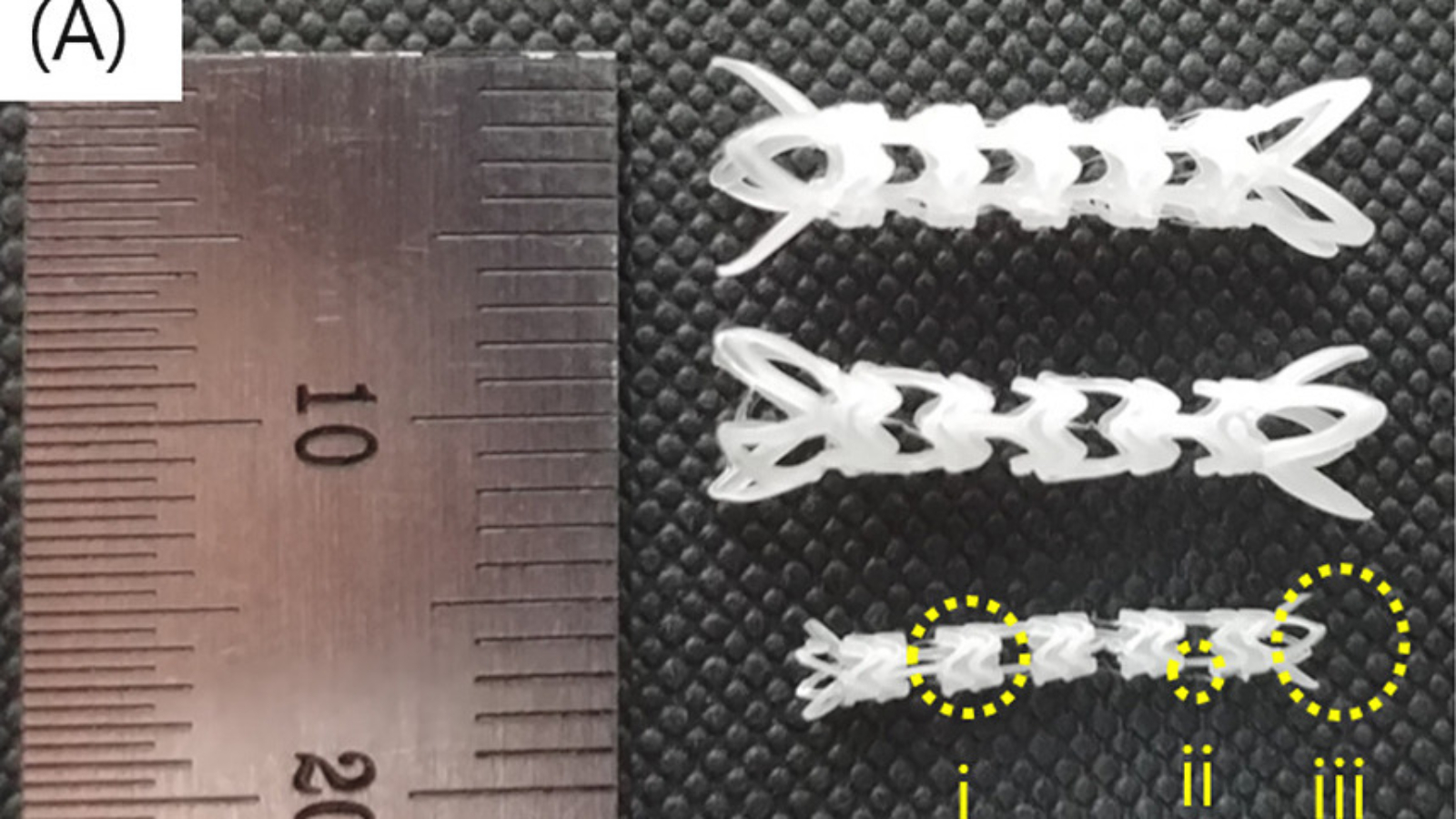

In order to fabricate their additive stents quickly and easily, the researchers deployed a ‘rotating rod’ system armed with multiple extrusion heads. During the process, the print heads were loaded with both a biocompatible PCL polymer and a cell-laden ECL matrix, and extruded onto a frame that would form the device’s reservoir.

The stent’s outer structure also featured an opened groove surface, that served both as an unidirectional drug releasing pathway, and a ‘bridge’ that reinforced its integrity. Once the team had loaded their devices with 10–20μl of hydrogel, they cross-linked the cells, and conducted a series of in-vitro viability tests.

SEM micrograph analyses showed that the team’s ECM matrix featured the dense, interconnected morphology necessary for supporting cell proliferation. Moreover, when the scientists deployed their stent within an immortalized human model, the esophageal cells exhibited a cell viability of more than 90 percent over 14 days.

Manufacturing on Demand

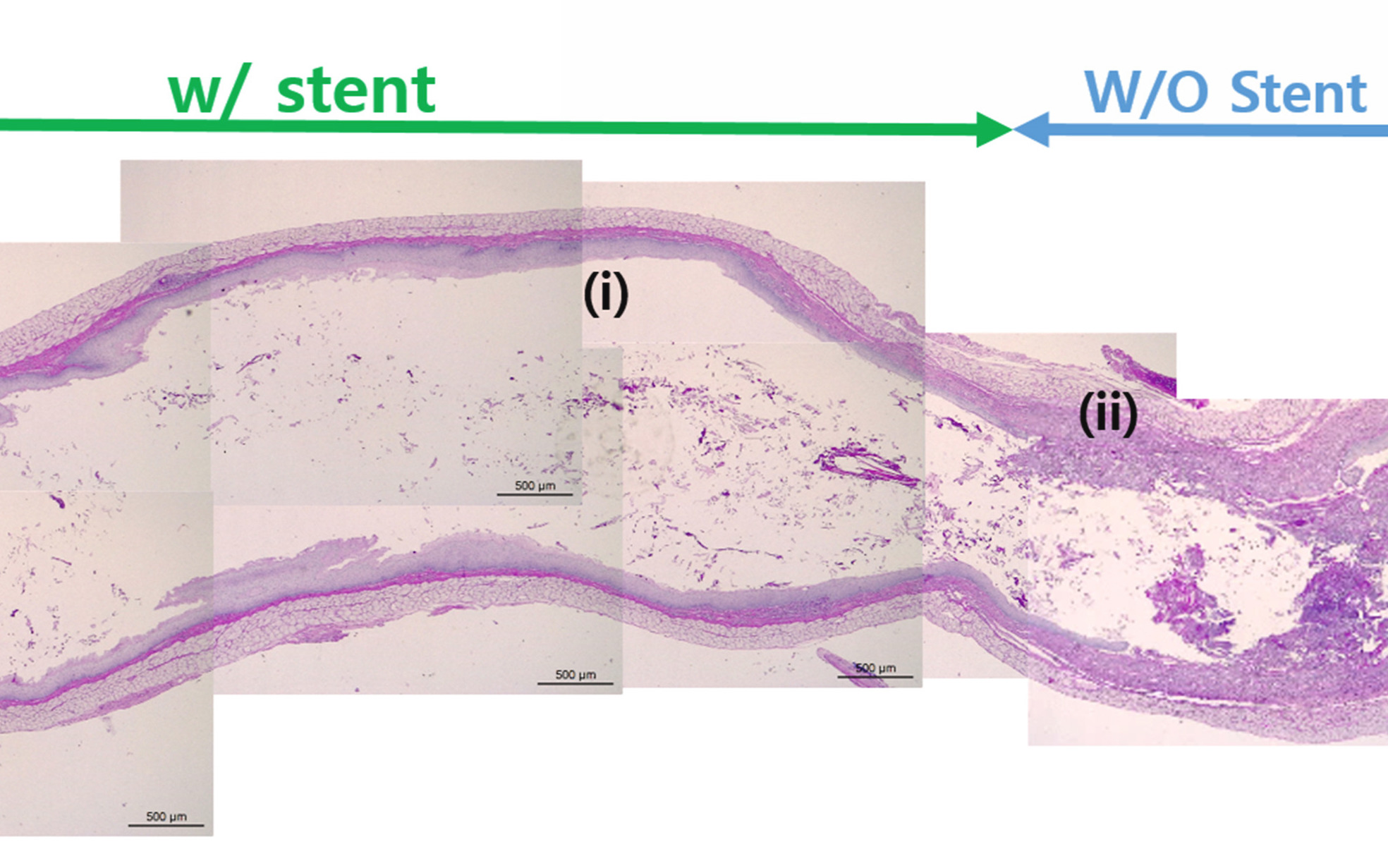

Further tests were then carried out on esophagitis-induced lab rats, in which some were fitted with the team’s additive device, and others weren’t. Results showed that the untreated animals reduced their meal consumption, while those with the stent showed decreased inflammation, and increased their food intake after 23 days.

Although the scientists conceded that there may be “radiobiological differences” between rats and humans, they added that they had ultimately induced the desired therapeutic effects. As a result, the team consider their stent to be both a direct treatment for esophagitis, and when loaded with other types of cell, other inflammation-based injuries too.

Combatting dysphagia using 3D printing

3D printing has been adopted by several researchers in recent years, as a means of addressing the dysphagia-related discomfort caused to the sufferers of various diseases.

Scientists from the University of Technology Sydney (UTS) and Deakin University, have 3D printed meals that are both tastier and safer to eat for dysphagia patients. By using pureed food as ‘ink,’ the team were able to fabricate foods that appeared more like their conventional counterparts.

Elsewhere, researchers from the Irish Athlone Institute of Technology, have designed 3D printed pills that are much easier to swallow. The team used a combined FFF 3D printing and micro injection molding process to develop custom bilayer tablets capable of releasing drugs in specific quantities.

Similarly, British pharmaceutical firm FabRx, has developed 3D printed personalized medicine for children with the rare MSUD metabolic disorder. The life-long condition requires patients to take daily supplements, and the team’s tailored pills can be produced more rapidly and effectively than conventional alternatives.

The researchers’ findings are detailed in their paper titled “.” The study was co-authored by Dong-Heon Ha, Suhun Chae, Jae Yeon Lee, Jae Yun Kim, Jungbin Yoon, Tugce Sen, Sung-Woo Lee, Hak Jae Kim, Jae Ho Cho and Dong-Woo Cho.

* This article is reprinted from 3D Printing Industry. If you are involved in infringement, please contact us to delete it.

Author: Paul Hanaphy

Leave A Comment