The US Department of Energy’s Oak Ridge National Laboratory (ORNL) has significantly demonstrated what large-scale, ultra-fast 3D printing is capable of, aiding in the construction of the Local Motors 3D printed car, producing a 3D printed Shelby Cobra for President Barack Obama to feast his eyes on, and, most recently 3D printing Printed Utility Vehicle and an accompanying house. ORNL has already licensed their technology to Cincinnati, Inc., which produces their Big Area Additive Manufacturing (BAAM) machines using ORNL’s 3D printing and materials technology. Now, ORNL has signed a non-exclusive licensing agreement with Youngstown, Ohio’s Strangpresse LLC to use the lab’s large-scale 3D printing patents.

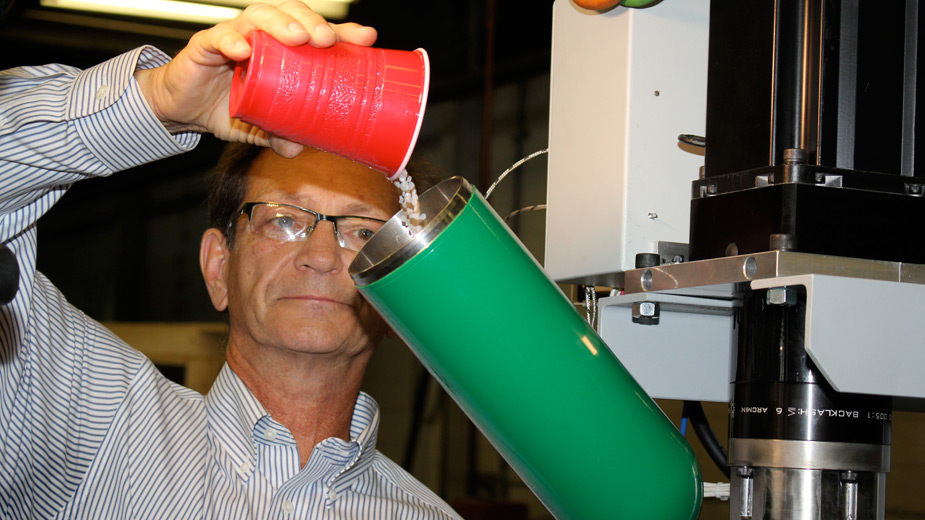

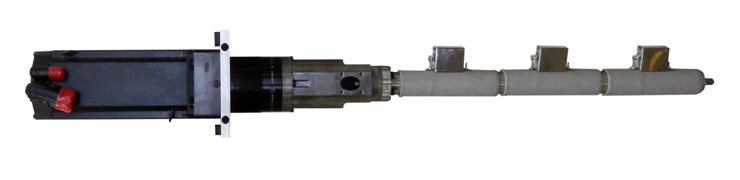

The agreement will see Strangpresse able to use any of ORNL’s patents related to materials, processes, and controls for large-scale manufacturing. As a Hapco Inc. affiliate, which manufactures industrial extruders for 3D printing among other things, Strangpresse was previously working to produce 3D printing feedstock from resin pellets using its own industrial extruder.

Strangpresse President Chuck George said of the agreement, “We’re very pleased to be joining with ORNL to carry large-scale additive manufacturing technology to the marketplace. Our leadership team has over 70 years of experience in the thermoplastics extrusion industry, and we see this partnership as a great opportunity to expand this technology.”

Eugene Cochran, ORNL senior commercialization manager, contributed, “The additive manufacturing industry is starting to take notice of some of the ORNL intellectual property. ORNL is interested in identifying and working with other companies interested in engaging in this space.” Lonnie Love, leader of ORNL’s Manufacturing Systems Research group, added, “Our goal is to demonstrate the potential of large-scale additive manufacturing as an innovative and viable manufacturing technology. We want to improve digital manufacturing solutions for the automotive industry.”

As ORNL has demonstrated technology capable of extruding composite materials at high speeds, with the additional ability to refine printed parts with an industrial CNC router, it’s possible that the licensing agreement will see Strangpresse develop equipment with these capabilities, but it is difficult to determine if that is the case at the current moment.

Leave A Comment