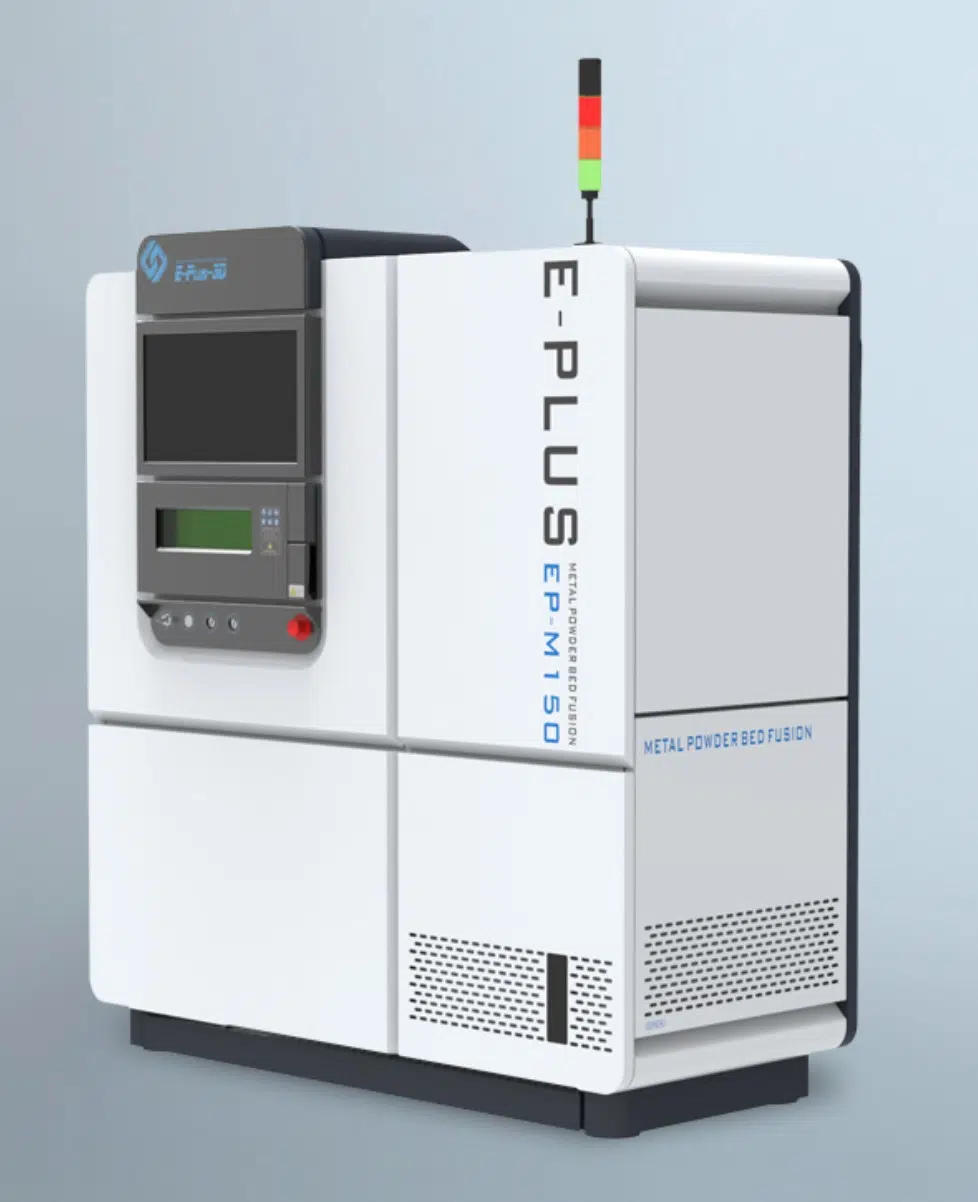

Oqton, a software provider, acquired by 3D Systems last year, that helps manufacturers increase innovation and efficiency by intelligently automating production, and Eplus3D, a leading global supplier of metal 3D printing solutions, have entered a strategic dental 3D printing partnership. Through this collaboration, both companies intend to enable dental laboratory professionals to increase productivity and provide a better service to their customers. This will be made possible by making Oqton’s AI-powered Manufacturing OS platform available to users of Eplus3D’s metal 3D printers. The combination of Oqton’s Manufacturing OS, and Eplus3D’s printing technology, as well as both organizations’ deep dental expertise, is intended to result in dental solutions that include full traceability and automation.

As we know, the patient-specific nature of dental restorations makes it an optimal application for additive manufacturing. Yet, for dental laboratories that are trying to integrate AM into their production workflows, they are often challenged by a lack of qualified personnel and the need for time-consuming, repetitive workflows, as well as regulations and certifications such as the EU Medical Device Regulation and ISO-13485 that require end-to-end traceability of machines, people, and material, at every step of the dental workflow.

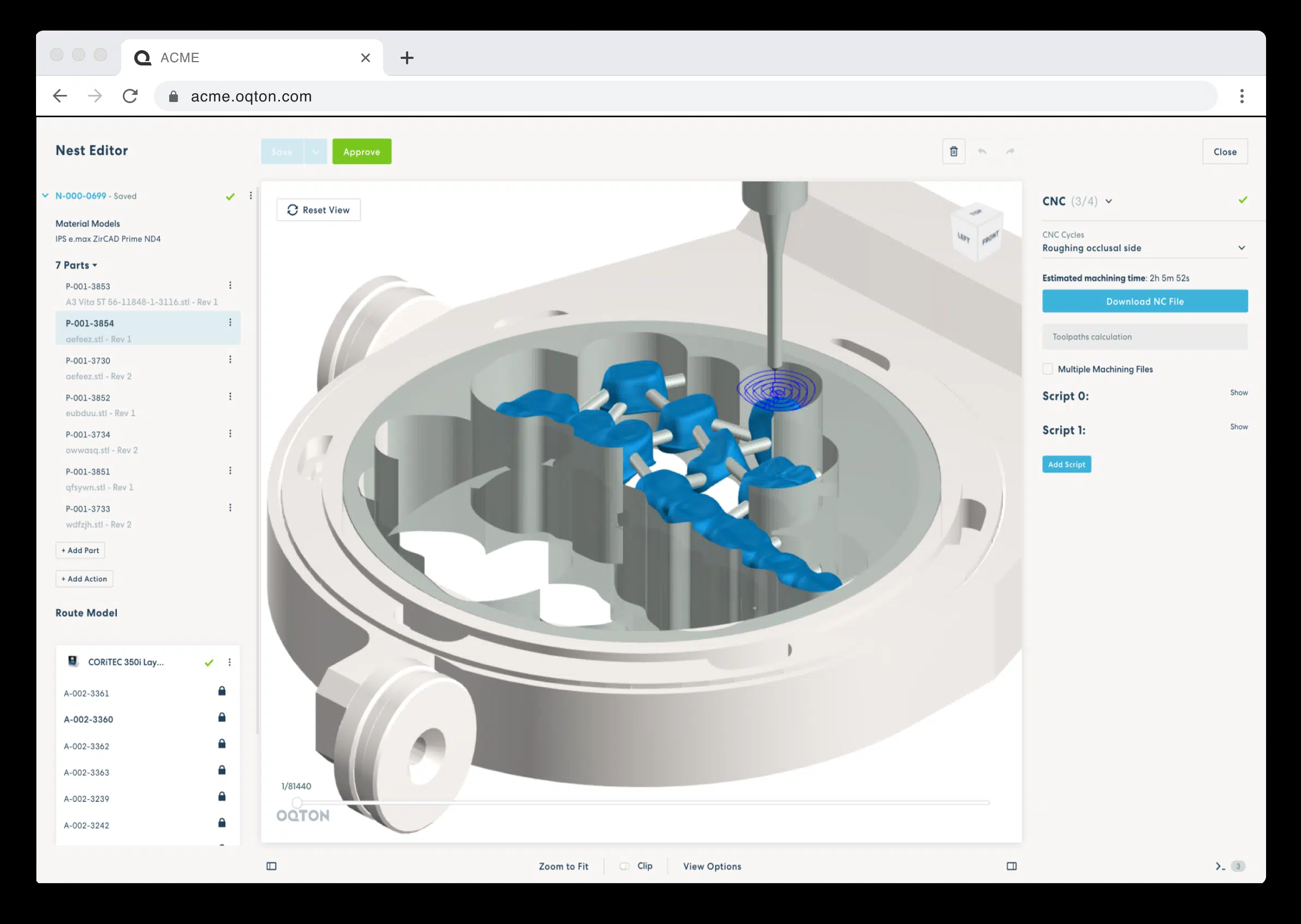

With Oqton’s Manufacturing OS, Eplus3D’s customers will have full transparency and traceability across the production workflow through manufacturing execution system (MES) and machine monitoring (IoT) capabilities – increasing efficiencies and providing greater peace of mind.

Manufacturing on Demand

By leveraging AI, Oqton’s Manufacturing OS automates the end-to-end workflow, from initial design to preparing files for production which can help significantly reduce person-power requirements. Oqton’s software also includes high-density layered nesting and interlocking 3D nesting of removable partial denture (RPD) frames allowing the fit of significantly more parts in the printer, as well as optimized support strategies that require less post-processing time. The Manufacturing OS also enables scheduling and planning for a customer’s workforce, machines, and material, across multiple production sites with full version history to facilitate regulatory compliance.

“We’re excited to officially recognize Eplus3D as a trusted partner amongst a host of forward-thinking industry leaders,” said Kris Wouters, General Manager of Healthcare at Oqton. “We are impressed with their commercial success based on the metal 3D printing technology they’ve developed, and its ability to help dental labs produce patient-specific devices such as crowns, bridges, and RPD frames. As we move forward, we will continue to deepen our technical collaboration, further helping customers achieve desired results with improved productivity while maintaining regulatory compliance.”

“Our collaboration with Oqton first began in 2018, as we set out to fully integrate their innovative Manufacturing OS into our Eplus3D printers,” said Mary Li, Head of the Overseas Division at Eplus3D. “Since that time, we’ve become increasingly acquainted with their expertise and technology, and are impressed by the easy-to-use, smart algorithms they’ve created. We’re looking forward to our continued collaboration to simplify production workflows for our customers – helping them unlock the full potential of AM to accelerate industrialization.”

Oqton and Eplus3D’s customers are already realizing the benefits of this partnership. “Oqton allows us to get the most out of our EPlus3D printer. It significantly simplifies and improves our workflows compared to our previous software solution, and more importantly, for dental parts, it almost completely automates the data preparation. Oqton saves us invaluable time setting up each build,” said Willem Van Cauwenberge, Head of Engineering at MT3D.

* This article is reprinted from 3D Printing Media Network. If you are involved in infringement, please contact us to delete it.

Author: Edward Wakefield

Leave A Comment