The Polish 3D Printer manufacturer, OMNI3D, has launched their latest model, the Factory 2.0 Production System. It is said that its operating costs will be up to “5 times lower” than other industrial solutions, and is currently being used by customers in three continents across the world. These customers are part of various different industries, such as electronics, engineering, automotive, aviation, as well as companies who are designing their own production lines and offering 3D printing services on demand.

The printer itself was first announced around this time last year, but OMNI3D has finally been able to announce the Factory 2.0’s immediate commercial availability. The price is available on request. The printer was showcased at the Innovations Technologies Machines Fair in Poznan last month.

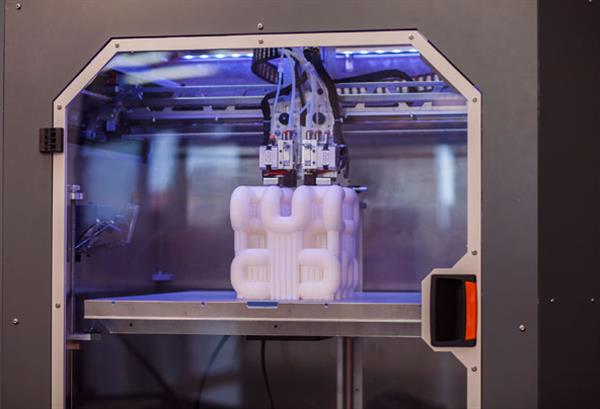

The Factory 2,0 printer is a Fused Filament Fabrication (FFF) printer, which has print space of 500mm x 500mm x 500mm, as well as two print heads, and a closed and heated chamber. This machine has also been optimized for industrial use, and also works well with Simplyfy3D, a popular form of 3D printing software.

SD card connectivity and a 7-inch touchscreen allows the printer to work as a machine by itself, without the use of a PC, so connecting a computer to the machine isn’t a necessity.

“The device is of great interest, primarily because of its technical parameters, attractive price, and low operating costs,” said Sławomir Mirkowski, responsible for operations and finance at OMNI3D. “We estimate that, compared to other industrial solutions on the market, the cost of buying our 3D printer is 4 times lower, and operating costs can be up to 5 times lower—depending on the application. This means the devices can be used by small and medium-sized companies that have not yet been able to afford them.”

The Factory 2.0 production system is a suitable means to producing spare parts for not only machinery and production lines, but also for the production of jigs and fixtures and prototyping. OMNI3D believes this new product will offer a comprehensive solution for a wide range of 3D printing applications in the industrial field. The company also offers consultations, installation, maintenance and training.

“The use of 3D printing globally is constantly increasing,” said Konrad Sierzputowski, responsible for technology development at OMNI3D. “It is mainly used for the production of spare parts for production lines and equipment (33%), prototyping (16%), in R&D departments and education (10%), production of models (9%), and patterns for metal castings (8%). The technical parameters of Factory 2.0 mean that it can be used in all these fields.”

Factory 2.0 3D printer technical specifications:

- Print technology: Fused Filament Fabrication (FFF/FDM)

- Compatible materials: ABS-42, ASA-39, HIPS-20

- Print area: 500 x 500 x 500 mm

- Layer height: 140 micrometers – 300 micrometers

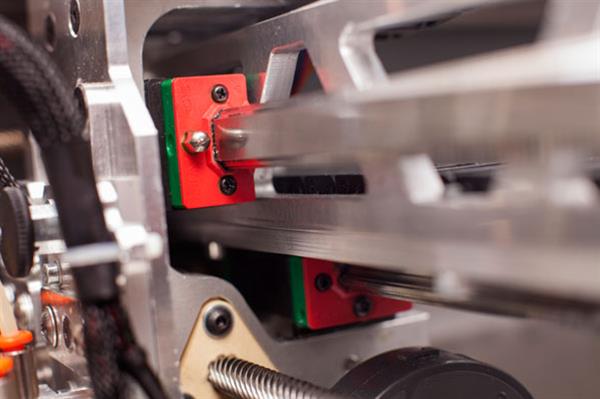

- Positioning precision: XY: 7.8 micrometres Z: 0.6 micrometres

- Heads: 2 replaceable extruder modules, liquid-cooled

- Chamber: aluminium, closed, thermally insulated

- Working platform: heated glass surface

- Maximum head temperature: 360 °C

- Operating temperature: 20-35 °C

- Filament diameter: 1.75 mm

- Head diameter : 0.4 mm

- Software: Simplify3D

- Connection: SD card

- Display: 7-inches LCD touch screen

Leave A Comment