Back in December last year, Nissan unveiled its Ariya single-seater concept car using the powertrain of the all-electric Ariya SUV. The development of the ground-breaking, bespoke, single-seater car chassis, with its futuristic and sleek appearance, showed what a fully electrified performance motor could look like.

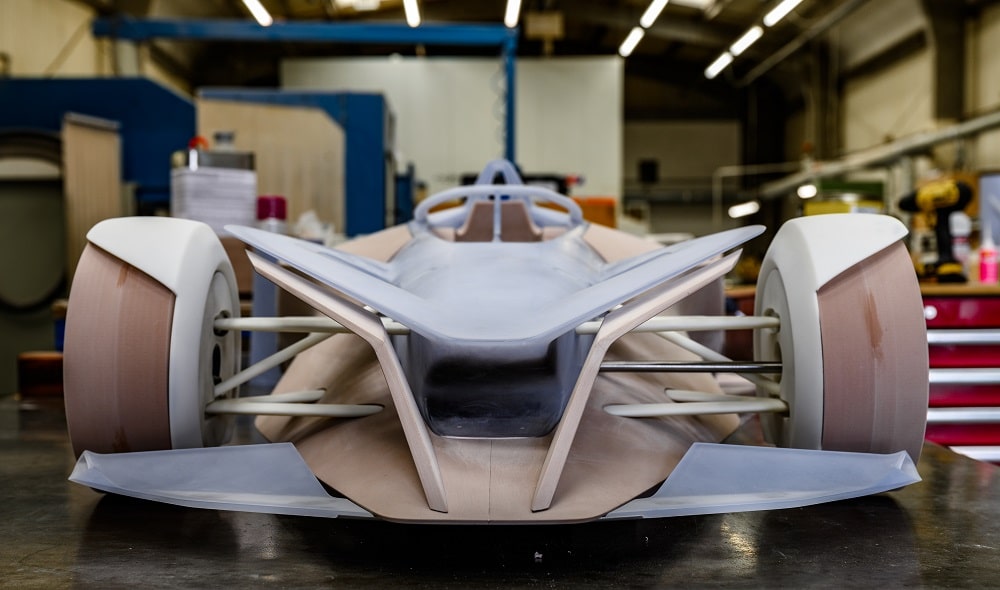

The concept car’s Formula E design, with near 400 bhp and all-wheel drive, turned heads when the public was given its first glimpse – due to its aerodynamic wheel covers and bronze coloring. Nissan was reportedly so happy with the car’s design that the company asked Herts-based Ogle Models to create a one-third scale model to keep in the reception of its UK Design Centre in Paddington, London.

“We have previously built full-size interior mock-ups of the first Qashqai and Juke models, so we were delighted to work with Nissan again on this exciting project,” said Philip Martin, Director at Ogle.

Manufacturing on Demand

The build of the Nissan Ariya model took almost 500 hours, including the CNC machining, 3D printing, and painting. The choice of material was governed by the weight and complexity of the parts, which were created using CNC machining and SLA printing.

After all the parts had been created, they were assembled with allowances made for the paint, using magnets and screws. The model was attached to a plinth before the whole thing was disassembled for the painting and application of graphics. The car was then reassembled and secured to the plinth.

“It was quite a complex project. Because the CAD model had only A surface data, we had to create the B surface which added thickness and features so something physical could be produced, ensuring that no undercuts were created, so the individual parts could all fit together like a jigsaw puzzle,” said Philip Martin. “We were extremely pleased with the finished model, which was made even more satisfying when we received such positive feedback from Nissan’s design center.”

You might also like:

6K Energy and ONE sign joint development agreement: “ONE is recognized in the industry as chartering exciting new milestones with their Gemini and Aries battery technologies,” said Sam Trinch, president of 6K Energy. “This agreement allows us to leverage the power of our UniMelt microwave plasma to extend performance of the chemistries, while keeping production on US soil.”

* This article is reprinted from 3D Printing Media Network. If you are involved in infringement, please contact us to delete it.

Author: 3D Printing Media Network

Leave A Comment