North American Lighting (NAL), a Koito Group Company and an automotive lighting systems manufacturer for vehicle manufacturers, has started using MakerBot’s METHOD X AM capabilities to increase the company’s assembly production efficiency.

With eight facilities across the US, NAL provides advanced lighting technology, engineering design expertise, and state-of-the-art production capabilities. For a manufacturer like NAL, which works with some of the largest automotive OEMs in America like Ford and GMC, speed and precision are critical. To that end, assembly production tools are essential to ensure that production continues smoothly. If a part breaks – it could mean extended lead times and added costs.

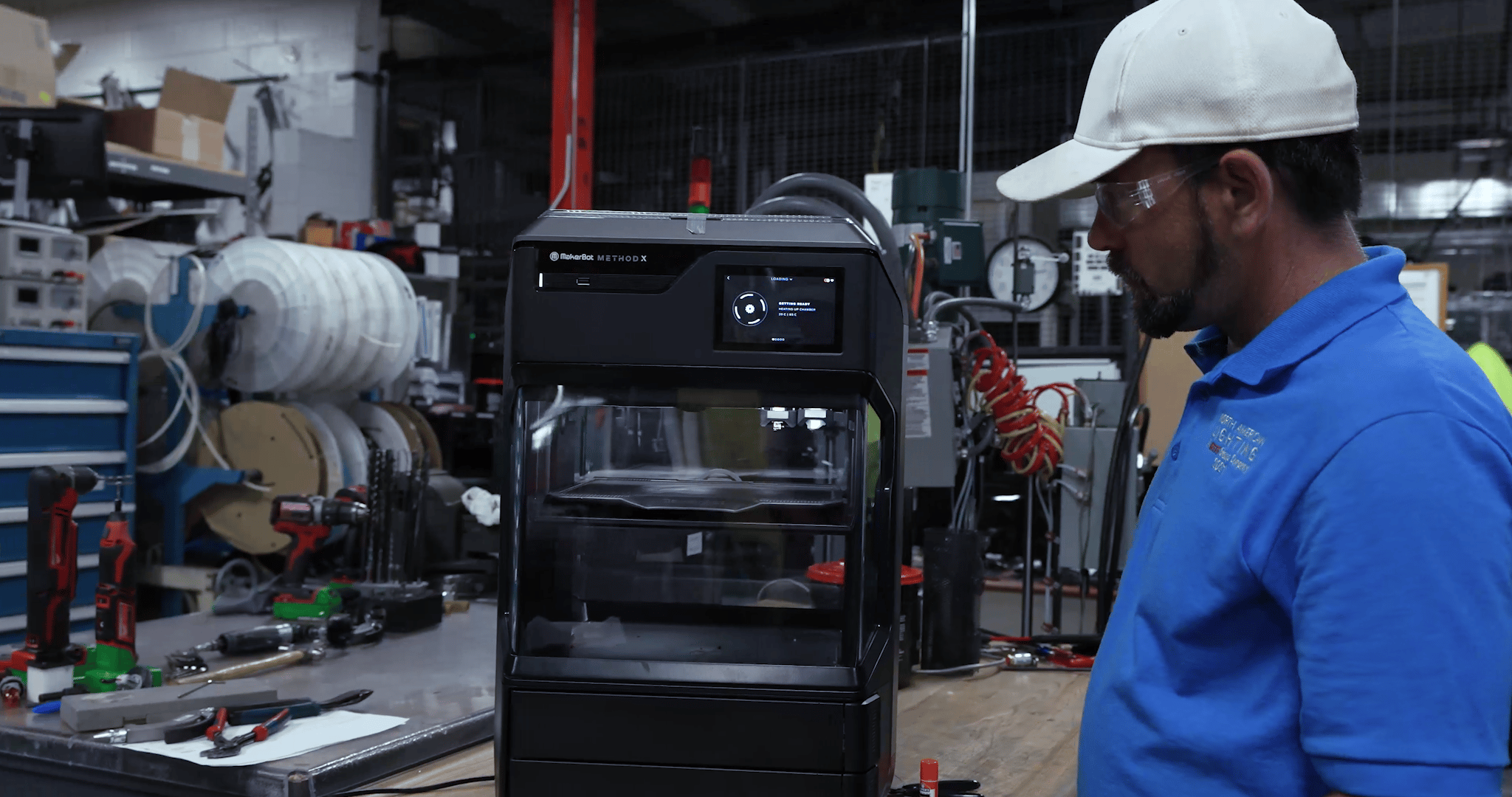

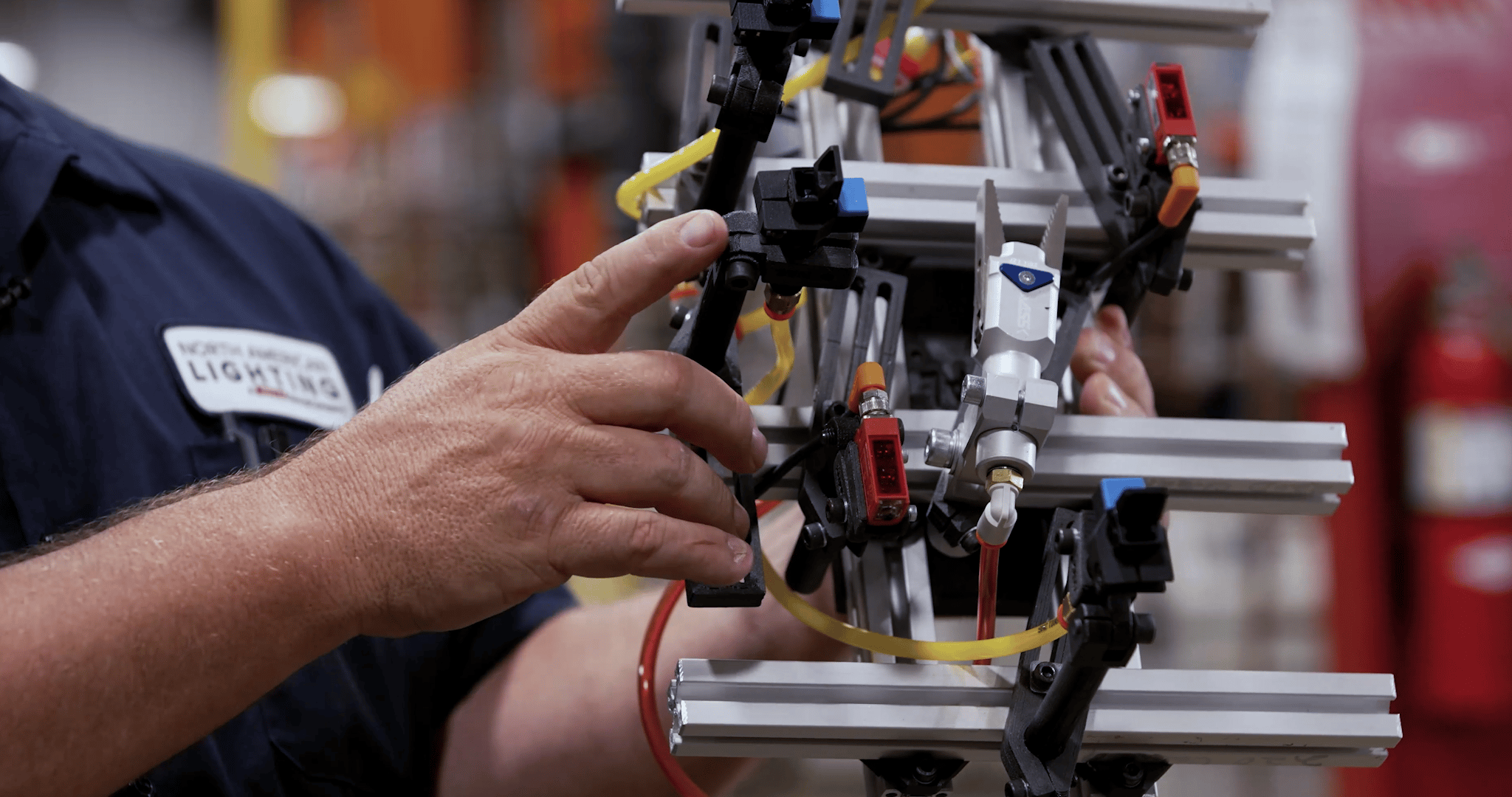

Joey Carpenter, production engineering technician, began using 3D printing to bring tooling production in-house and reduce potential disruptions. Carpenter was new to 3D printing when he was introduced to the MakerBot METHOD X series in early 2022. Since then, Carpenter, who handles robotic builds and cycles in new end of arm tools for production runs on new launches, has become the resident expert.

Before 3D printing, Carpenter and his team relied on external vendors to design, produce, and send back parts that they would need. Receiving a new part could take several weeks. This was less than ideal since orders were frequently late, forcing them to readjust their timelines.

“Now with a METHOD X in-house, there is minimal wait time,” said Carpenter. “In 12 hours, we have what we need to build an end-of-arm tool. Not only does this drastically reduce our wait times, but we are also seeing a massive cost reduction. The cost to 3D print a part in nylon carbon fiber is one-third the price of what we were paying for outsourced aluminum parts.”

“In addition, since we started 3D printing, our overhead costs decreased by half because we don’t have to stock up on excess parts,” he continued. “We have reduced part inventory by 50%. Now all of our tool designs are digital so they’re easier and quicker for us to access, iterate, and print as we need. Instead of waiting weeks, we can turn parts around in five days, from design to assembly.”

In the Flora factory, the robots use around 200 end-of-arm tools a year, which are built in-house. Bringing tooling production in-house has allowed the team to significantly reduce costs while also saving significant amounts of time.

While Carpenter mainly prints end-of-arm tool parts, he has also found new applications where he can utilize the versatility of METHOD X. “We’ve also used in-house mockups and prototypes for water fittings and parts like that for future use. We prototyped with carbon fiber in house within a matter of three days, rather than outsourcing it which could take a month to get back,” he said.

Manufacturing on Demand

“We’re finding that it’s very easy to replace aluminum with carbon fiber parts. With weight reduction and durability, carbon fiber is comparable to aluminum,” noted Carpenter. “With the LABS extruder, MakerBot and Jabil materials offered on the METHOD X, the tolerances and the consistency of your prints are far better than you can imagine.”

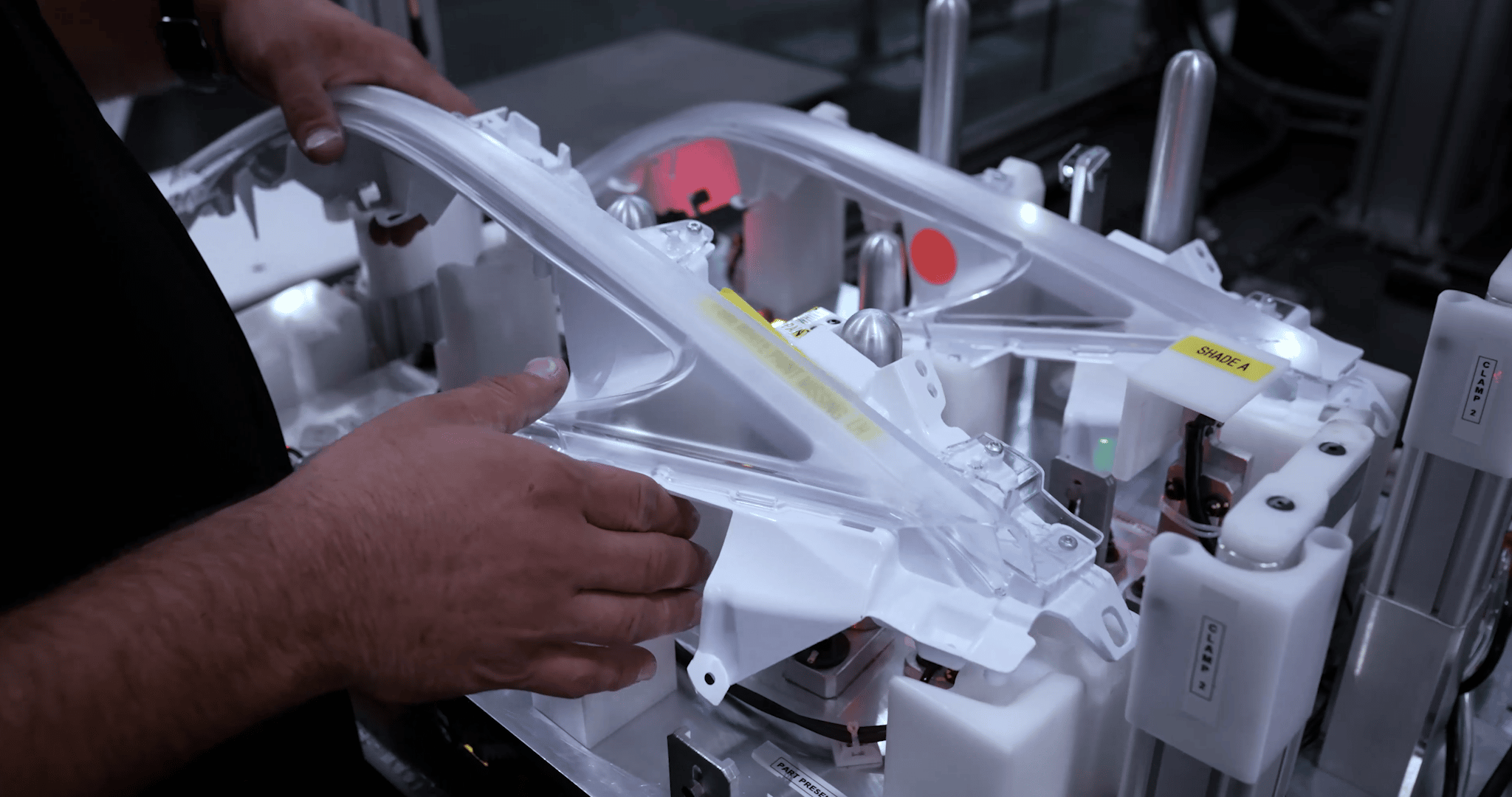

Carpenter’s team isn’t the only one using METHOD X at the Flora facility. The Assembly and Lighting team at NAL also began using the printer to produce nest blocks for the assembly line. The nest blocks go into the tooling on the assembly line and are used to keep parts in place while the machine is working on them. Before METHOD X, the team would have to bring in one of their tool shop vendors to access their needs. They would have to then wait for the vendor to design the part and build it as well as wait for a quote for the part to be approved, before receiving the final product.

“There would be a four-to-six-week lead time before getting a part back,” said Dee Jay Griffith, manufacturing engineering technician. “And the cost would be pretty high – With METHOD X, we’re able to print a full nest for less than 10% of the cost and we’re able to do that faster.”

“The METHOD X and 3D printing helped my workflow by enabling faster lead times and cost savings that comes with being able to print my own things,” Griffith noted. “We’re now able to accomplish what we need to on these assembly lines faster and without having to rely on vendors’ timelines.”

Primarily printed in carbon fiber and PolyMax PC – the nest blocks are lightweight and durable. Since printing them months ago, Griffith has not yet seen any wear on them. He is also experimenting with different materials, constantly finding things they would like to print. For example – camera mounts, grease tips, leak test seals, and more.

While the teams at NAL are experiencing a significant savings in cost and time when using 3D printing, those are not the only factors for their use of METHOD X. Its ease of use and seamless ability to print carbon fiber as well as other industrial-grade materials with the MakerBot LABS Experimental Extruder have made METHOD X a must-have in their facility.

“We’ve already ROI’d this machine and we’ve only had it for a few months. Just in the savings of what we’ve already printed, not to mention the time we’ve saved doing it ourselves as opposed to waiting for a shop to come in to get it done,” said Griffith.

“I work for a multi-billion dollar company and can afford any 3D printer out there but yet we have five MakerBots in house right now and there’s a reason for that,” concluded Carpenter.

You might also like:

Scaling composites 3D printing into a new dimension: Martin Eichenhofer (CEO), Giovanni Cavolina (CCO) and Chester Houwink (COO) founded 9T in 2018 with the goal of delivering the next generation of high-performance manufacturing and aspiring to mass-produce high-performance composites as easily as metals by automating and digitizing the production workflow of composite production. The only way to do this, they realized, was to address the complexities of anisotropic materials and the manual-labor-intensive continuous fiber reinforced thermoplastic polymers (CFRTP) manufacturing.

* This article is reprinted from 3D Printing Media Network. If you are involved in infringement, please contact us to delete it.

Author: Edward Wakefield

Leave A Comment