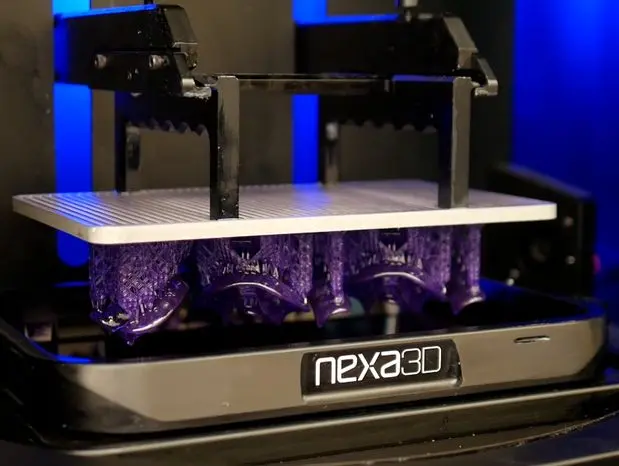

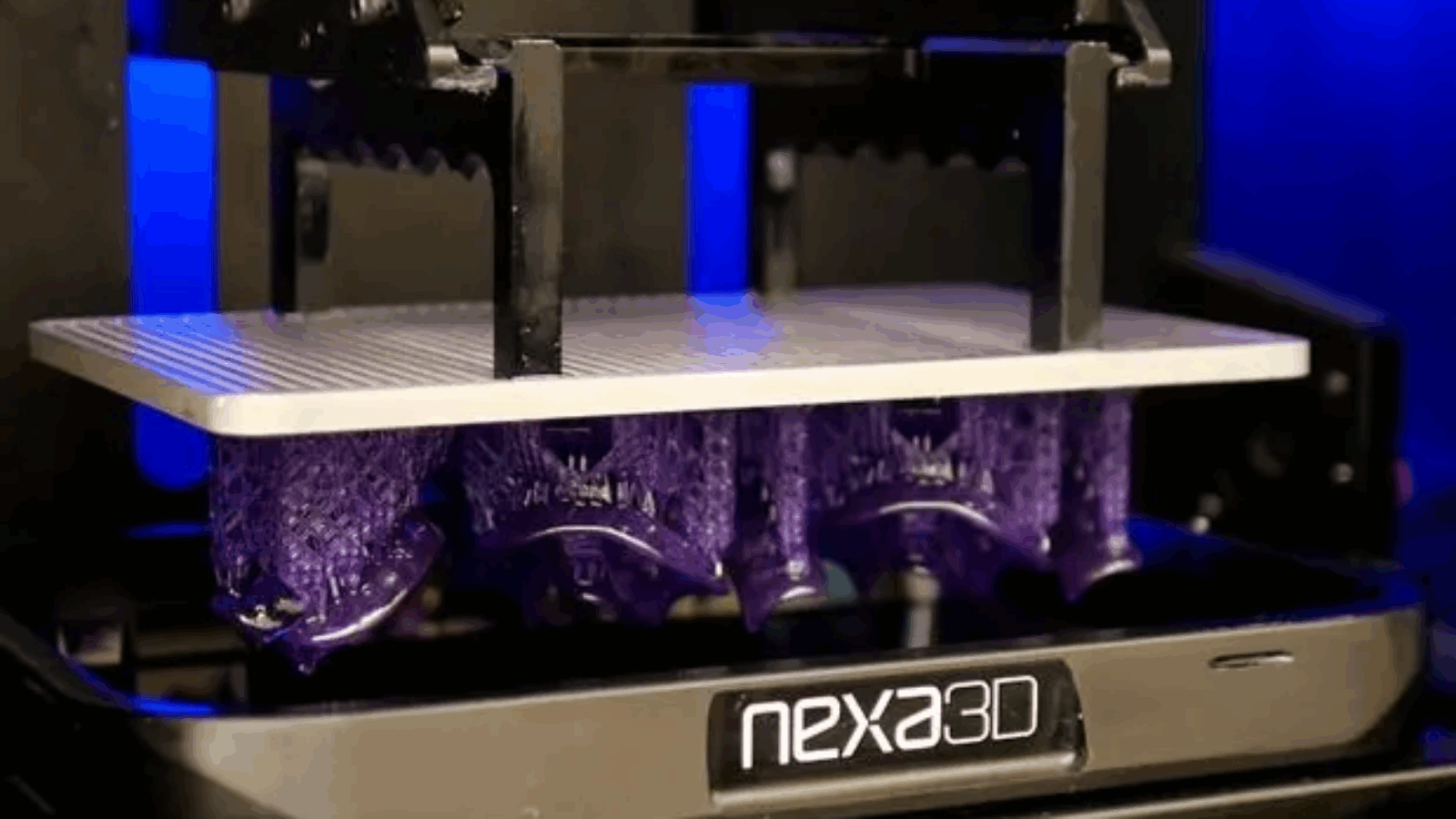

Nexa3D‘s ultra-fast NXE 400 3D printers will make all Keystone KeyPrint 3D printing resins for the global dental industry. This powerful new combination comes with Keystone’s best-in-class, FDA-cleared night guard resin, KeySplint Soft and KeyModel Ultra. All Keystone precision dental resins are manufactured in the USA, and available immediately through Nexa3D’s expanding global channels.

The companies’ partnership also applies circular economy principles to every phase of their material formulation and printing processes. Through the implementation of end-to-end validated workflows, both companies are rigorously minimizing process waste, reducing energy consumption per part and working with customers around the world to reduce their overall carbon footprint.

Nexa3D’s high-resolution NXE 400 printer combines a 16-litre build volume, extreme print uniformity, advanced process algorithms, modular design for onsite automation and intelligent optimization. These advantages are said to offer twenty-fold gains in productivity

“We are thrilled to tailor our entire portfolio of KeyPrint resins for Nexa3D, a company that is fast emerging as an additive polymer market leader,” said Keystone Dental President Ira Rosenau. “During our extensive internal optimization and validation testing, we confirmed that the NXE 400 produces outstanding quality prints at high volumes, making it an ideal additive manufacturing partner for the dental industry. We expect Nexa3D users to have an outstanding experience with our growing line of KeyPrint resins.”

Manufacturing on Demand

The printer yields impressive part-throughput gains while offering the lowest cost of ownership in its class on the market. These gains are compounded further by Keystone’s resins, including KeySplint Soft. This material delivers a unique combination of strength needed to protect teeth while retaining flexibility. It is designed to improve patient comfort.

“We are excited to partner with a company of the calibre and reputation of Keystone to jointly advance the range of available functional and affordable dental solutions for labs and practitioners,” said Avi Reichental, co-founder, Chairman and CEO, Nexa3D. “At Nexa3D, we are committed to advancing 3D printing performance and productivity through internal innovations and external collaborations. We are particularly pleased to partner with Keystone to bring our combined portfolio of 3D printing dental solutions to market, delivering new levels of speed, productivity and efficiency to the dental industry.”

Every NXE400 3D printer comes with accelerated part-to-print capabilities, including fully integrated build set up and print management software that can prepare part files for printing in half the time of other solutions. The printer is also fully interoperable with all leading digital dental workflows and providers.

Both the NXE400 3D printer and KeyPrint resins are available for purchase now.

* This article is reprinted from 3D Printing Media Network. If you are involved in infringement, please contact us to delete it.

Author: Adam Strömbergsson

Leave A Comment