Nano Dimension Ltd., a leader in the field of 3D printed electronics (NASDAQ, TASE: NNDM), announced today the opening of its first Customer Experience Center (CEC). The Israel location is the first of several Nano Dimension Customer Experience Centers planned worldwide to accelerate the adoption of additive manufacturing for electronics development. Nano Dimension’s CECs will also serve as customer and reseller training facility and sales support centers.

The CEC is an integral part of Nano Dimensions’ go-to-market and business development strategy, and signals the company’s shift from its initial R&D stage to full product commercialization. At the CEC, customers, distributors and strategic partners will see first-hand the company’s ground-breaking 3D-printing technology, and will learn about designing and producing electronic components and circuits using additive manufacturing.

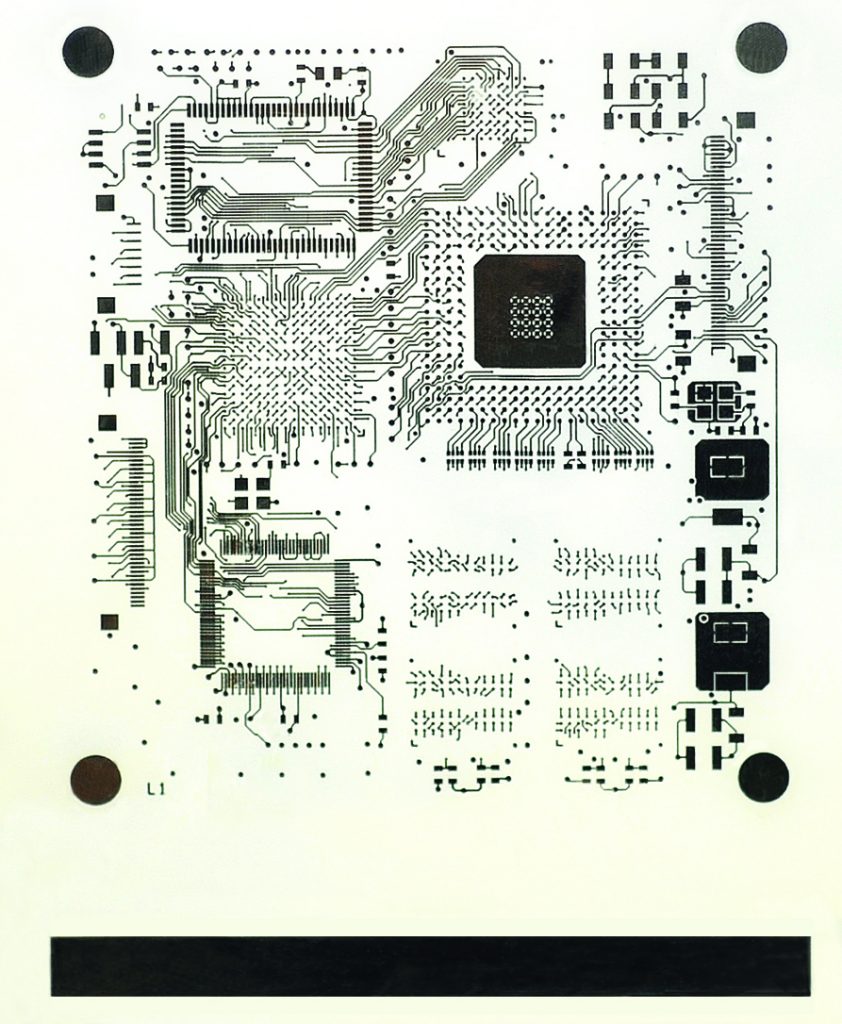

Located at the company’s headquarters in Ness Ziona, the CEC will feature Nano Dimension’s commercially-available DragonFly™ 2020 Pro 3D Printer, specifically designed for professional electronics development. Printing will be demonstrated on-site, and samples produced by the DragonFly will be on-hand for viewing.

Some of Nano Dimension’s top talent will operate the CEC, including technicians and engineers specializing in additive design and production. Nano Dimension specialists will also provide tailored advice to the specific needs of each company about the best way to implement 3D-printed electronics for specific applications.

“Companies that are engaged in computing and actuating hardware products are under pressure to speed up their concepts into market-ready products quickly, while meeting the need for small, faster and more functional electronics,” said Amit Dror, CEO of Nano Dimension. “We are making agile hardware development immediately accessible through our Customer Experience Center, which will serve as a one-stop shop for advanced additive manufacturing technology. For the first time, customers can leverage Nano Dimension’s expertise and experience the benefits of electrified additive manufacturing applications on site.”

The company sees great value in demonstrating the unique capabilities of its new professional 3D printer, the DragonFly 2020 Pro, for Industry 4.0 preparedness. This is thanks to the printer’s ability to quickly and easily produce proofs of concept, design validations and professional multilayer prototypes and functional parts in-house. The revolutionary printer allows for 3D-printing of a multilayer circuit boards overnight, allowing users to rapidly test and iterate resulting in better workflow efficiencies. This process can radically reduce development risks and shorten time to market.

Leave A Comment