The Center for Innovative Technology’s (CIT) CIT GAP Funds early-stage investment firm headquartered in Virginia, has invested in Metallum3D, a local 3D printing materials manufacturer and service provider.

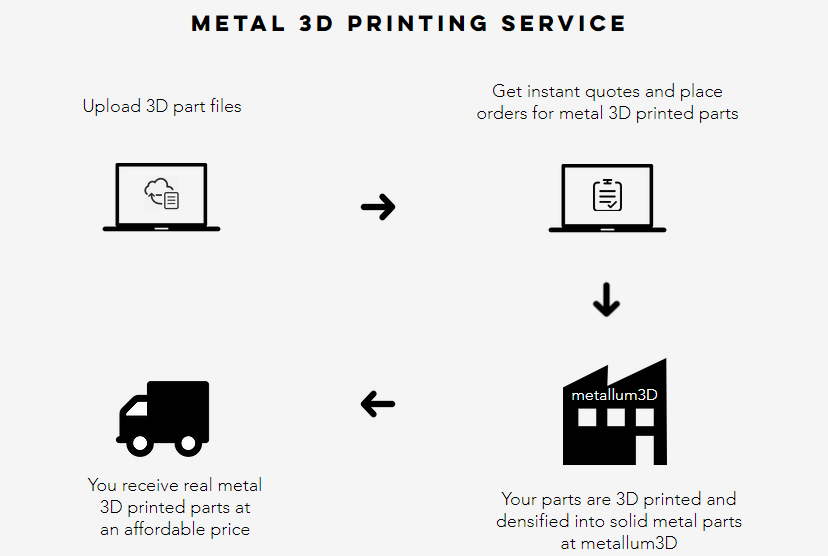

With this new capital investment, Metallum3D will be able to carry out plans to grow its team; move to a larger office; expand its product development capabilities; and attract partners to its platform. In addition, the company is now in a position to undergo the beta launch of its metal 3D printing service, expected Q2 2019.

Nelson Zambrana, CEO of Metallum3D, comments:

“We are grateful for the support of CIT GAP Funds, whose investment will play an important role in our growth and disruption of the metal 3D printing industry.”

Bringing metal to the masses

The primary objective of Metallum3D, according to Zambrana, is to provide, “more access to affordable metal 3D printing materials and services.” With its metal 3D printing service, the company hopes to enable businesses and individuals to sidestep the capital investment of new hardware for metal additive. On the materials front, this is fulfilled by Metallum3D though a patent pending FFF filament, which Zambrana has confirmed takes advantage of readily available, and low-cost MIM grade metal powders in a polymer matrix. The idea with this material is that, after 3D printing on a typical desktop 3D printer, the object is placed in a furnace to debind its plastic content and sinter metal particulates together.

Other companies making use of such a concept include The Virtual Foundry, material sponsor for the first annual Industry Awards trophy, Markforged, in the Metal X machine, and Desktop Metal, in its Studio System.

Supporting the MIM-powder-fused filament, Metallum3D has also developed a patent pending Microwave Densification process, used for debinding and sintering 3D printed objects. According to the company, its process “reduces part debinding and sintering time by over 80%.”

Furthermore, “Parts can be processed to full density with ~20% shrinkage or infiltrated with a secondary metal resulting in full density and shrinkage of less than 3%.”

Metallum3D currently offers filaments fused with Stainless Steel 316L, and Tool Steel H-13.

CIT GAP Funds

A service line of non-profit innovation accelerator CIT, CIT GAP Funds is actually a family of seed and early stage investment funds sprawling a range of different specialist technology areas. At present, five funds in total comprise the CIT GAP Funds family: GAP Fund I; GAP BioLife Fund; GAP Tech Fund; Commonwealth Energy Fund (CEF); and Virginia Founders Fund.

Typically, CIT GAP Funds initial investment is made up to the value of $100,000. In larger syndication rounds, this can extend up to around $500,000. Full terms of the Metallum3D investment however, including the amount granted, remain undisclosed. Thomas Weithman, Managing Director of CIT GAP Funds, comments, “A lot of businesses do not have the funds to utilize current methods of metal 3D printing technology. Metallum3D is changing that narrative for businesses, big and small, by providing an affordable, accessible solution.”

“CIT is excited to be a part of this mission, and we are certain that Metallum3D’s technology will meet many needs in the market.”

Speaking with Alex Euler, Investment Director at CIT, Industry learned the value this firm sees in the technology. “There is a significant and underserved market for full-product cycle metal 3D printing,” Euler comments, “Current metal technologies are cost prohibitive and desktop 3D printers are often underutilized. Metallum3D’s technology addresses both of these issues. CIT’s investment in Metallum3D enables firms operating in industries with exacting, industrial grade materials and fabrication – such as aerospace – to finally overcome prohibitively expensive barriers to market access.”

“Advanced manufacturing is on the Commonwealth’s Technology “Roadmap,” and as such, is considered a vitally important area for economic and technological growth across Virginia. This technology, in particular, seeks to streamline both manufacturing and innovation processes – and that potentially benefits many startups in Virginia and beyond.”

Voting is now open for the 2019 Industry Awards. For all of the latest additive manufacturing business news subscribe to the Industry newsletter, follow us on Twitter and like us on Facebook.

Looking to hire additive manufacturing experts? Advertise through Jobs to reach our highly specialized talent pool.

Featured image shows a spool of Metallum3D filament. Photo via Metallum3D

Leave A Comment