Meltio, an additive manufacturing company that creates affordable, easy-to-use metal 3D printing solutions, using wire LMD technology,

These two new sales partners clearly show the company’s ambitious plans for global expansion. Just last month, Meltio announced its partnership with another two sales partners – Tecmahe in Argentina, and ELH in Singapore.

Manufacturing on Demand

Meltio offers a pioneering metal 3D printing solution that enables industrial applications with a process built around welding wire – one of the safest, cleanest, and most affordable metal feedstock in the market. Meltio’s open material platform enables the ability to achieve exceptional mechanical properties using a single wire, dual wire, or wire and powder materials. Meltio’s process currently supports steel, titanium, and inconel alloys.

Considering that manufacturing clients in Japan are increasingly demanding large metal 3D printing that is

repeatable and cost-effective, 3DPC intends to combine Meltio’s wire LMD technology with its design, simulation, and solutions business to empower these Japanese manufacturers. 3DPC will focus on building a supportive ecosystem for Meltio’s technology in the territory – partnering and driving business opportunities alongside technology centers, tooling machine companies, robotic integrators, academia, and industry.

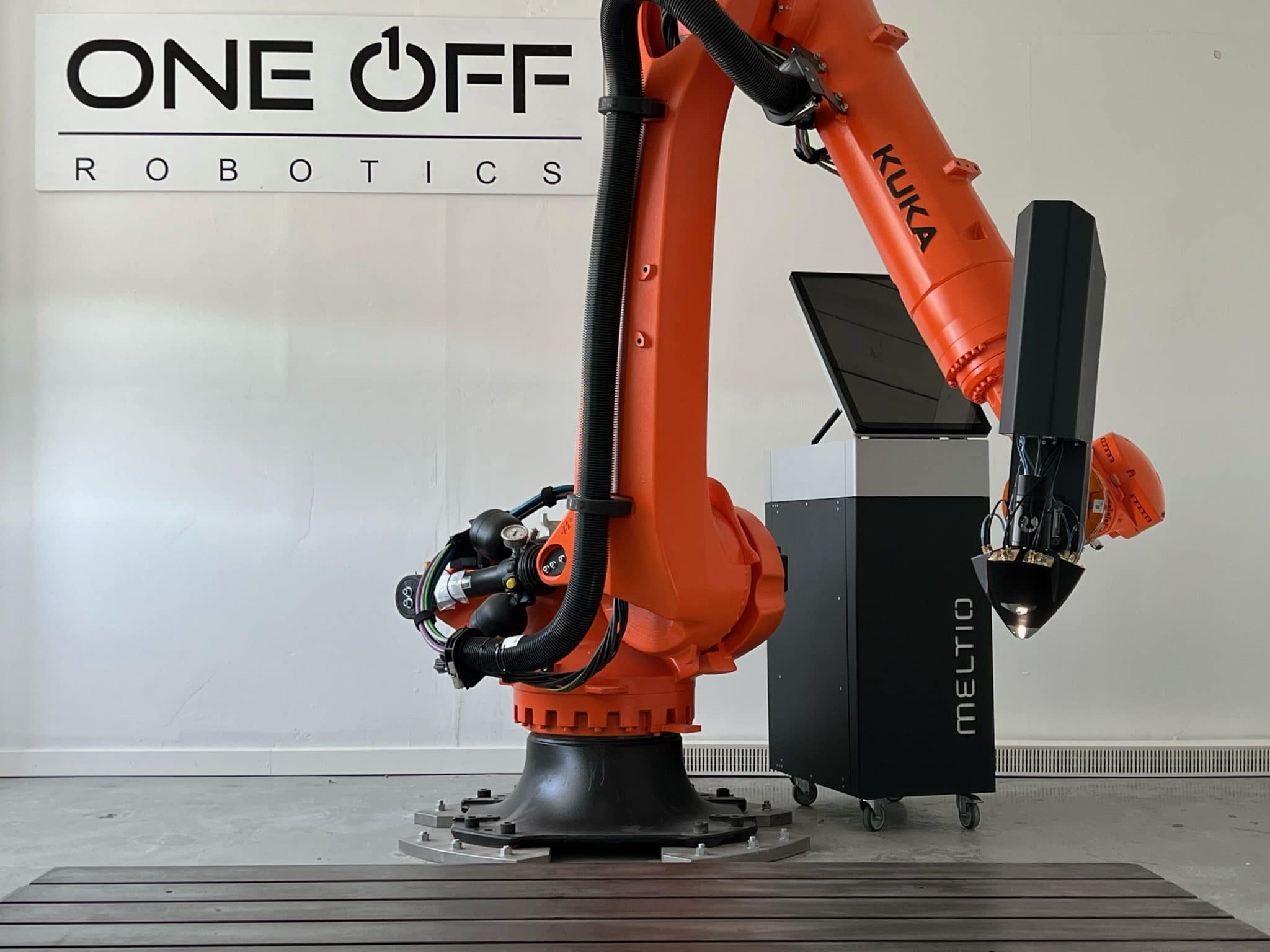

With regards to Meltio’s new North Amercian sales partner – One Off Robotics is a technology company that utilizes industrial robots as fabrication tools. These systems have applications in large-part manufacturing in the aerospace, marine, and composites markets. One Off Robotics specializes in advanced additive and subtractive applications – including thermoplastic and metal 3D printing, robotic machining, and laser cutting. One Off Robotics will focus on the distribution, integration, and support of Meltio’s metal additive manufacturing solution for robotic systems in the US market.

You might also like:

Sintratec expands its distribution network to Oceania: Project 3D’s team guides its customers through the entire 3D process. Fitzgerald is an expert in the field of additive manufacturing – his specialties range from 3D scanning to product design, and reverse engineering.

* This article is reprinted from 3D Printing Media Network. If you are involved in infringement, please contact us to delete it.

Author: Edward Wakefield

Leave A Comment