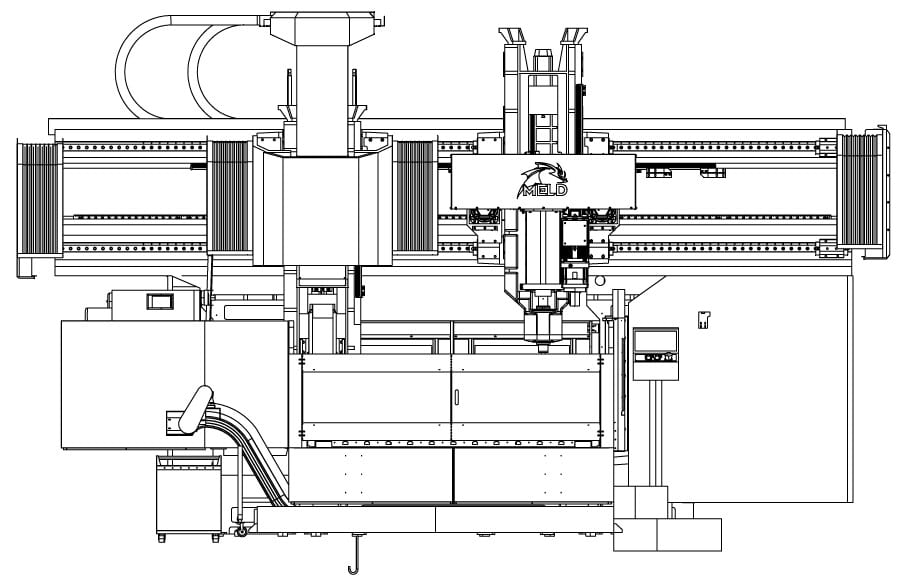

MELD announced their newest machine, 3PO, at Formnext 2022 in Frankfurt am Main, Germany. It features a MELD additive system with an integrated subtractive head that is independent of the additive portion. It boasts an immense cubic build space while eliminating the need for a separate subtractive machine.

3PO, named after Star Wars droids like the other MELD printers, has a print capacity of 157.5” x 106.0” x 39.4” (4,000mm x 2,700mm x 1.000mm) with a print volume of 380 ft3 (10.8m3). It offers continuous printing capability for large scale parts.

The subtractive capabilities include a standard 3-axis head, with an optional 5-axis head. With a maximum travel speed of 475 inches per minute (12m/minute) parts can be in service quickly and efficiently.

The MELD process is a no-melt, open atmosphere technology capable of printing large metal parts at a scale not yet seen in the AM market. It yields isotropic, fully dense parts with low residual stresses. Because it is a no-melt process even un-weldable metals can be printed. MELD parts can be printed in hours or days as opposed to months or years for forged parts.

Manufacturing on Demand

The MELD technology is well suited to address several challenges facing the defense sector along with other industries:

- Supply chain disruptions caused by scarcity of metal spare parts

- Excessive repair and rework backlog caused by long lead times for backordered parts

- Lost operational availability caused by stress fractures and metal fatigue to equipment

“In response to customer demand, we’ve increased the size of parts possible with MELD, and added subtractive functionally to machine in features throughout the build,” stated CEO Nanci Hardwick.

While 3PO is the first MELD commercial off the shelf hybrid machine, it’s not the first machine that MELD has been involved in that includes subtractive capabilities. The MELD technology is being deployed in a machine for the U.S. Army’s Jointless Hull Program. This “World’s Largest Metal Printer” incorporates additive and subtractive capabilities with a print volume of 20’ x 30’ x 12’ (6.1m x 9.1m x 3.7m).

You might also like:

SLM Solutions presents concept for metal PBF parts up to 3 meters long: So SLM Solutions decided to go further beyond the extremes of manufacturing with its next trailblazing and record-breaking solution, which again changes the scale of what can be manufactured. The breakthrough solution will shake up the industry by enabling the production of high-quality metal parts up to a size of 3.0 x 1.2 x 1.2 meters (LxWxH). The large part machine concept contains a core unit and a build envelope flexible in size that allows the manufacture of components in individual dimensions. Coupled with the advantages of SLM technology, the game-changer offers its users the possibility of a perfectly tailored production with individual requirements – without the familiar limits.

* This article is reprinted from 3D Printing Media Network. If you are involved in infringement, please contact us to delete it.

Author: Tess Boissonneault

Leave A Comment