Megnajet, a UK-based fluid management specialist, has launched the JetSource HFR Core, a new fluid management system designed to meet the challenges of high-volume, inkjet printing and additive manufacturing applications.

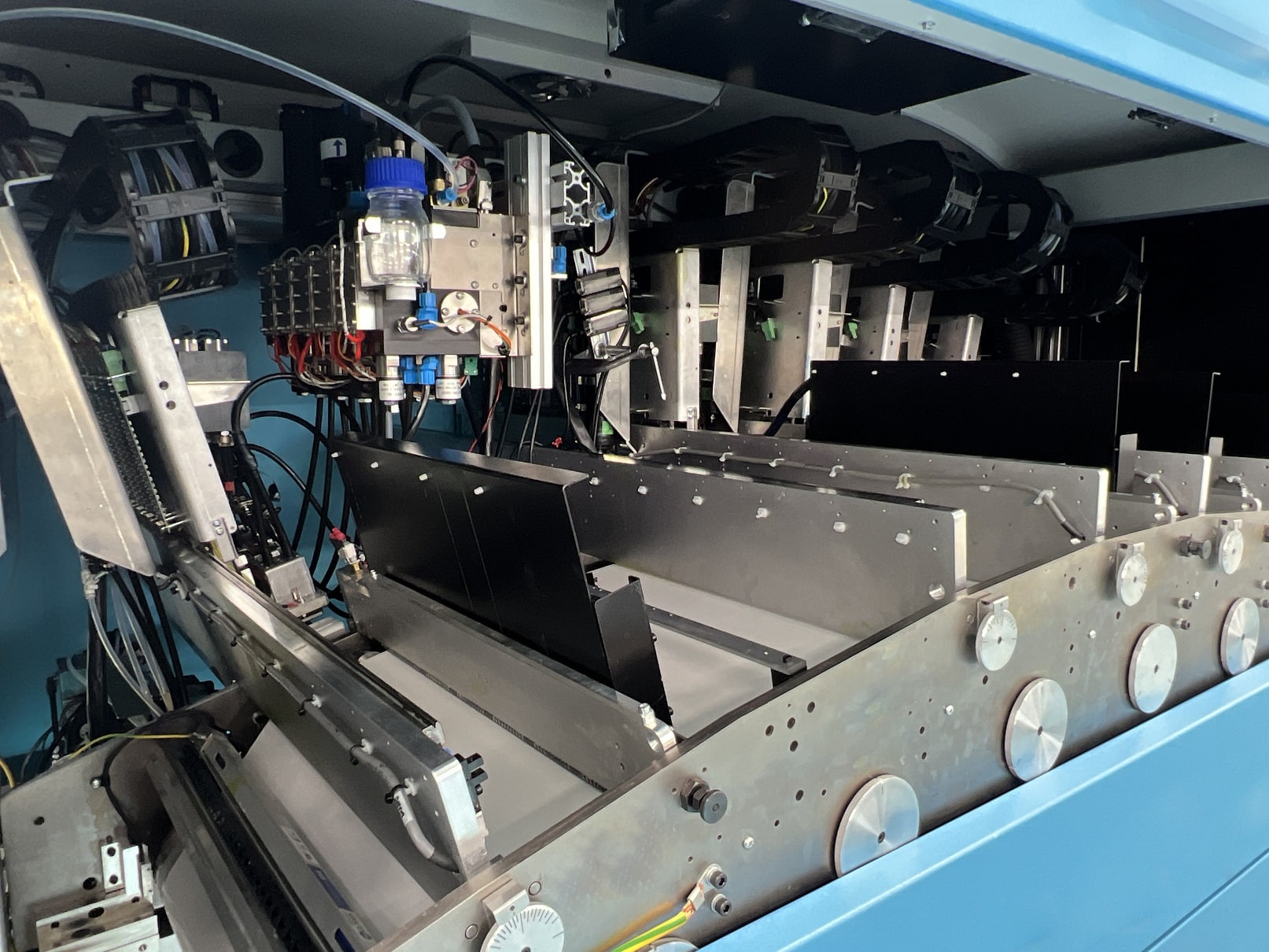

Developed in response to the increasing industry demand for jetting large volumes of fluid, Megnajet’s latest fluid management system recirculates fluid at up to four liters per minute across up to five independent ports for printheads.

Mike Seal, General Manager at Megnajet said, “We’re delighted to launch the JetSource HFR Core as it meets the growing demand to precisely and accurately control large volumes of fluid across high productivity printheads.

“JetSource will help our customers to access the many opportunities of high-volume inkjet applications, delivering print quality that is essential to their success, while saving them time, effort and resources in having to develop their own standalone solution.”

In addition, the JetSource incorporates a system architecture that minimizes any restrictions and enables peak flow rates to be achieved, thereby maintaining print system productivity.

Manufacturing on Demand

This innovation in inkjet fluid management systems helps OEMs and integrators to overcome the common challenges in jetting large volumes of fluids. The system provides accurate, high-quality results across a range of applications including labelling and packaging embellishments, special varnish effects, braille and high-build 3D printing.

Optimized tank volumes ensure continuous availability of conditioned fluids with the advanced dual heating and sensing system providing precise temperature regulation for jetting.

Pressure stabilization is also guaranteed with the JetSource HFR Core, providing a fast response to changes in print duty and maintaining control when ejecting large volumes of fluid. Thanks to a compressed air venturi system, it can react quickly and accurately to deliver high-quality print regardless of the duty cycle.

Easily integrated to customers’ inkjet systems, its compact nature and ease of use make the JetSource HFR Core the ideal fluid management solution in high-volume applications. Units can also be customized to suit specific fluid types, including the use of alternate body materials such as FDA-approved food grade acetal or a choice of gasket materials and customizations to user software.

The launch of the JetSource HFR Core opens up the opportunity for OEMs to take advantage of the benefits of high-productivity printheads and printbar-based architecture, without having to invest in developing their own solution.

You might also like:

Lithoz and Himed to develop 3D-printable medical-grade bioceramics: This joint effort, including Himed’s acquisition of a CeraFab S65 Medical printer, follows last year’s successful Formnext, where Lithoz received tremendous feedback on the launch of its significantly improved LithaBone HA 480 material. After searching for a strategic partner in the United States to better access the enormous potential of top-level surgery specialists there, this partnership forms the next logical step in the large-scale commercialization of this highly specific 3D printing product but also will form a powerful intercontinental pool of top researchers driving 3D-printable bioceramics to the next level. Partnering with Himed allows Lithoz to explore the potentials of other CaP phases within the highly sophisticated biomimetic forms their printers can make.

* This article is reprinted from 3D Printing Media Network. If you are involved in infringement, please contact us to delete it.

Author: Davide Sher

Leave A Comment