Materialise, and FacFox, the largest online 3D printing service provider in China, recently announced cooperation to pave the way towards industrial-scale 3D printing. They are working together on plenty of innovative projects to accelerate the digital transformation of manufacturing.

The cooperation between Materialise and FacFox is a win-win business model combining software and hardware in the 3D printing field. Materialise’s 3D printing software, Magics 3D Print Suite, has been applied for 30 years. The smart, convenient, and feature-rich software applications cover the entire 3D printing design and production process. It has made Materialise a leading position in the industry and brings an outstanding reputation.

Since FacFox entered the 3D printing industry in 2014, it has accumulated rich printing experience in the fields of automobiles, architecture, art, aerospace, medical, fashion, jewelry, furniture, etc. With over 600+ 3D printers, 100+ CNC milling and turning machines, 100+ materials, and 20+ post-processing options, FacFox has built a mature business pattern in model making, fast prototyping, customization, and low-volume production.

“With the integration of Materialise’s industry-leading software, FacFox can now handle all the steps of the AM workflow,” said Edi Weigh, the President and CEO of FacFox. “We have served large and startup companies as well as studios and individuals with one-stop solutions, and find there is a great potential in the global markets. Glad to have a collaboration with Materialise. We believe that we can provide customers with the best 3D printing solutions, create more value for our partners, and improve the competitiveness in the world.”

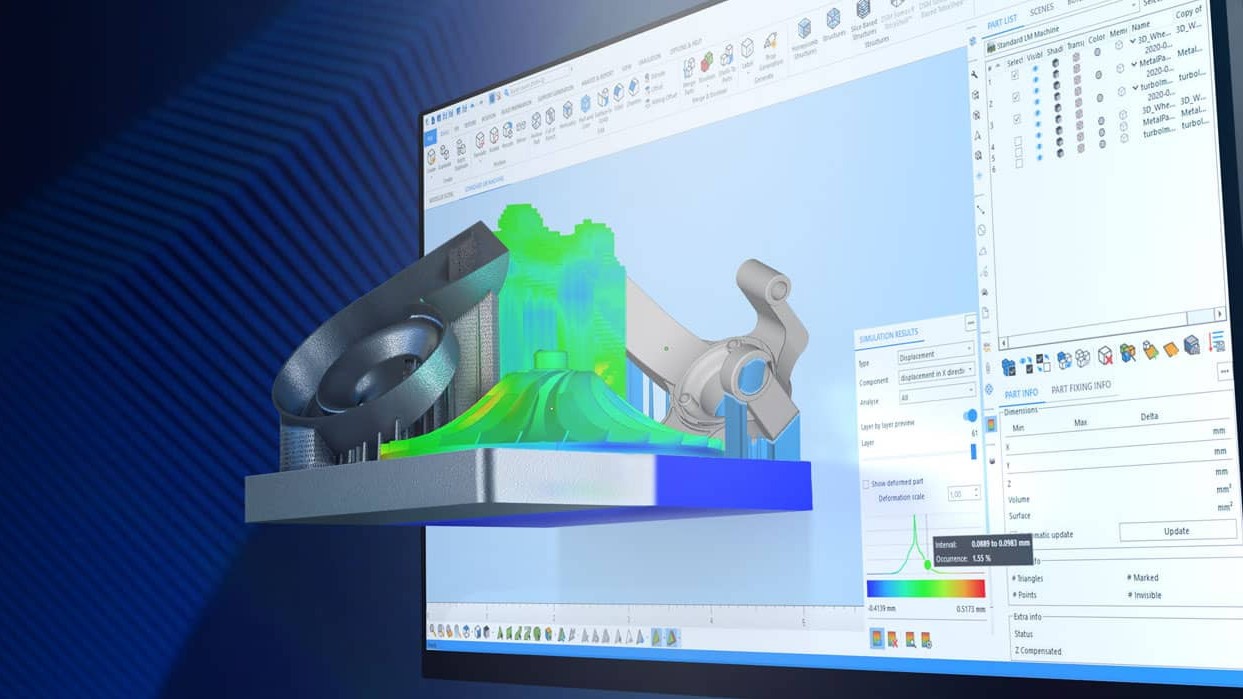

According to FacFox, Magics 3D Print Suite enables stability and fast responding speed and increases the convenience when importing nearly all file formats, repairing the STL files, editing and optimizing clients’ designs, applying textures and colors on marked areas, preparing the build platform, etc. It also provides advanced data preparation and traceability to relevant build-data, improves operation management, and production monitoring.

This partnership approach benefits both companies, and will also help advance the implementation of the technology throughout the entire market.

Leave A Comment