Mantle is officially launching its metal 3D printing technology for toolmaking, with the P-200 3D printer and F-200 furnace. The system was developed to simplify the way mold tool components are made and accelerate how manufacturers making molded parts – a $265 billion market – go from product idea to launch. Deliveries of the first production systems are planned for the first half of 2023.

Mantle’s technology reduces the time to create tooling components by eliminating or reducing many operations traditionally required to make precise, durable steel tool components.

Mantle’s solution is designed for ease of installation and use. “There is a massive skills gap in the injection moldmaking industry,” commented Hillary Thomas, Westminster Tool Vice President. “Mantle’s technology is so intuitive that, with minimal training, we can have someone quickly operating and running this machine. Mantle will help Westminster Tool change how we do business.”

Mantle’s system and patented TrueShape technology start with the P-200 printer, a hybrid system built on a CNC platform that integrates printing and machining to produce parts with the accuracy and surface finish required for tooling. The P-200 printer has a build volume of 200mm x 200mm x 150mm. The F-200 furnace, which sinters parts from the printer, produces tooling components that are durable and accurate. One F-200 furnace can sinter multiple parts and can support multiple printers.

Manufacturing on Demand

Two tool steel materials, H13 and P2X (steel comparable to P20), are durable, stable, and perform like traditional tool steels with secondary operations like machining, polishing, coating, and laser welding. Mantle’s easy-to-use software automates the printing process, including the generation of all toolpaths and machine instructions.

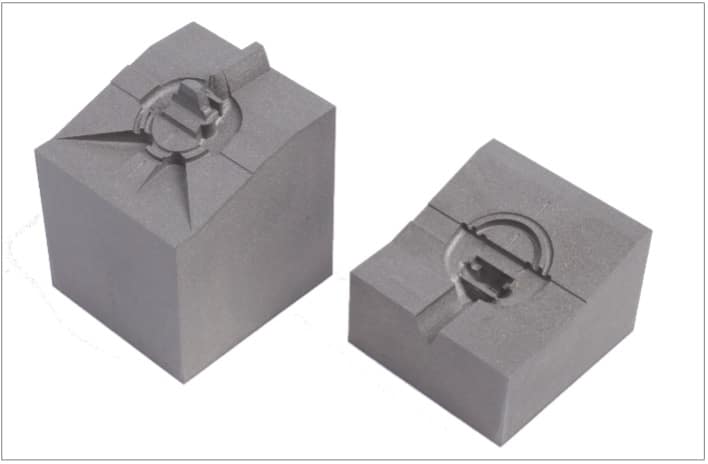

Recent customer success stories include Fathom Manufacturing, one of North America’s largest on-demand digital manufacturing platforms. The service provider reduced its toolmaking time by 45% with components made by Mantle’s technology. Fathom reduced its toolmaking operations from 200 hours to 110 hours by eliminating or reducing multiple operations, including CNC milling, EDM, and polishing. Fathom Manufacturing cavity and core inserts as printed with Mantle’s TrueShape metal 3D printing technology (left). Cavity and core inserts after Fathom finished the printed inserts and assembled them in their modular mold system (right).

Tessy Plastics, a global contract manufacturer specializing in injection molding and custom automated assembly solutions, surpassed 1.25 million cycles on a production mold built with Mantle components. The mold, which makes deodorant packaging, contains both Mantle H13 and P2X tool steel components and demonstrates the durability of Mantle’s steels in a demanding production environment. Tessy Plastics also realized a time savings of 60%, from 150 hours to 60 hours.

Nicolet Plastics, a full-service custom plastic injection molding company with three facilities in Wisconsin, will be installing one of Mantle’s first production systems. “As an injection molder, adding Mantle technology allows us to bring additional tool production in-house and increase the complexity of the tools and inserts we manufacture. We will significantly reduce the time it takes to produce production-quality tools and be able to start production in weeks versus months,” stated Tony Cavalco, Nicolet Plastics CEO. “Our tool designers and project managers will utilize the Mantle system for projects involving high-volume part manufacturing. Mantle technology will allow us to design conformal cooling channels to reduce molding cycle time and ensure the highest quality products for our customers.”

You might also like:

DBZ launches AION NX large format hybrid 3D printer: Resulting in cost savings of 80% for polymer 3D printing (as the machine uses direct pallet extrusion 3D printing) and delivering CNC machined parts with 70% reduced cycle time.

* This article is reprinted from 3D Printing Media Network. If you are involved in infringement, please contact us to delete it.

Author: 3D Printing Media Network

Leave A Comment