MakerBot has made a landmark decision to outsource the manufacture of its hardware to China.

The 3D printing giant has done a deal with Jabil, which will manufacture all the hardware at its facilities in the Far East. A number of staff, including designers, engineers, logistics and repairs, will stay with the company at a slimmed down facility in Brooklyn, New York, but layoffs are inevitable.

We don’t have any news yet on the number of staff that will lose their jobs, but MakerBot has cut its floorspace in its New York facility in half in the last year alone.

“It’s a specific, painful decision in the sense that we’re going to have to let some people go, but it’s captured over a much broader strategic decision, which is a very important one and a very positive one for MakerBot in the long term,” Jonathan Jaglom, MakerBot’s CEO, said in an interview with The Verge.

Mass production the reason?

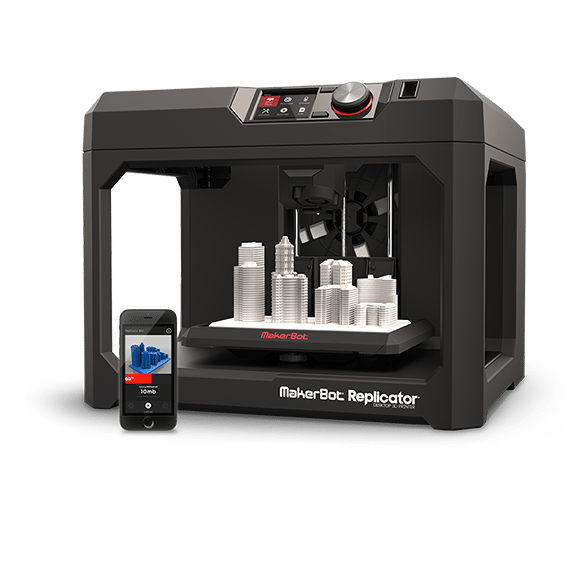

Jaglom claimed that the facility in the US could simply not keep up with the demand for consumer and professional 3D printers that we all know is coming in the years ahead. So for the good of the company he had to plan ahead and do a deal with a company that has the infrastructure in place to handle the volume.

While it anticipates a strong consumer demand, that is one market where MakerBot has conspicuously failed to make an impact. Deals with Home Depot and Micro Center came to nothing and the company even opened its own outlets in another failed experiment. It also laid off 20% of its staff, twice, in 2015.

Lawsuits added to MakerBot’s problems

On top of that there were lawsuits, claiming MakerBot wilfully sold faulty extruders. None of this looks good and it does suggest that Jaglom may be putting a positive spin on the news.

Obviously outsourcing to China will reduce overheads and it means that MakerBot can hold a third party responsible for quality control.

It also marks a mildly embarrassing U-turn for a company that has publicly professed its commitment to the US base. “The thing that we are very proud of is that it’s all happening in Brooklyn,” Jaglom said in 2013. “The launch of factory here today proves the fact that are committed to remaining here.”

After relinquishing half the company’s floorspace in Industry City, he said: “If we play our cards right — and I’m sure we are, we’re doing a lot of great things here — over time, the company will grow further, and through that growth we will bring more talent under our rooftop. Our DNA and our culture very much remains a Brooklyn one, we’re very proud to be here in Brooklyn.”

Was MakerBot ahead of the curve?

Others have now filled the consumer niche, but MakerBot may simply have been ahead of the curve and this deal with China could help it fix any quality control issues, reduce prices and make another assault on the consumer market. This would make it a positive move in the long run.

Of course the company can build on its success with industrial and educational partners. It’s hard to see how outsourcing manufacturing to China and gearing up for mass production, though, can mean anything but a renewed focus on the home user.

It is set to become a potent market in the years ahead and soon every home could have a 3D printer. If MakerBot can overcome the challenges of the last year and produce top quality printers with the right ticket price, then the consumer will not care where they are put together.

For the industry though, and for those that made their living at MakerBot, this is not good news.

Leave A Comment