International 3D printing service Sculpteo has made batch 3D printing productivity one of its main features for professional customers. To understand where 3D printing adoption is heading, the company commissioned an impressively in-depth international study titled The State of to outline the habits and the intentions of the growing community of professional 3D printing users and the scene looks bright.

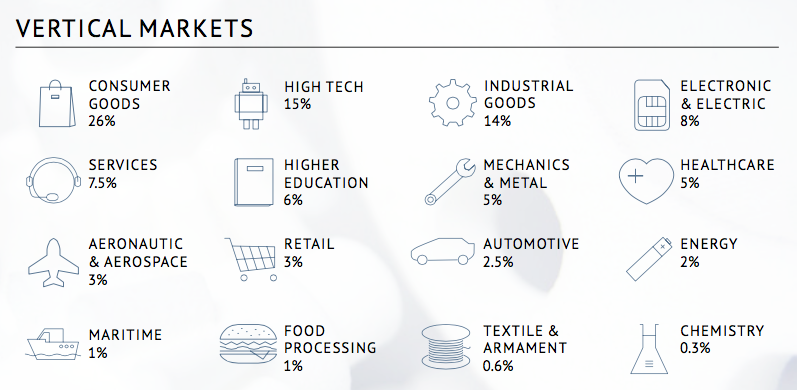

According to the study, which involved interviews with over 1,000 professionals operating in fields ranging from food processing to aeronautics, about half (44%) of respondents plan to increase spending on 3D prints by at least 50%, while as many as two-thirds (68%) expect an overall increase in the upcoming year. The expected increase is noted across several industries, reinforcing the impression that additive manufacturing is present and growing annually, and in all sectors.

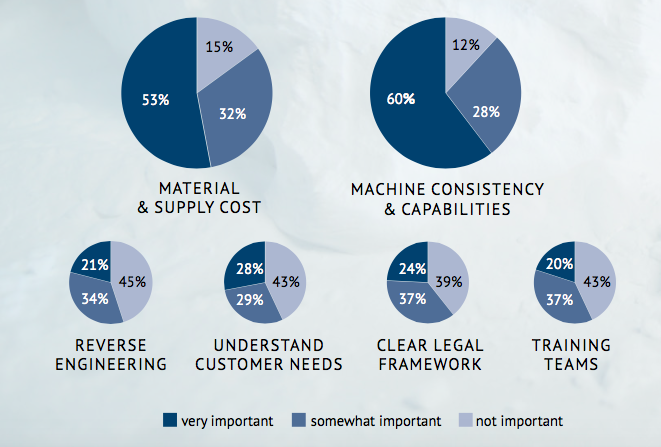

So, what is currently seen as the biggest limit for greater 3D printing implementation? According to Sculpteo’s study, over 50% of professionals consider very practical aspects of the technology – such as the price of supplies and machine capacity – to be the most important factors that need to be improved. Other, more theoretical aspects, such as training requirements, consumer needs, legal framework, and reverse engineering, were determining factors for only less than 30% of respondents.

The main drivers for 3D printing adoption were identified as “accelerating the development of new products and the ability to offer customized or limited-run products.” In this sense, users once again showed less concern for less concrete possibilities, such as enabling co-creation, increasing production flexibility, and improving spare parts management. These, which are probably seen as opportunities to capitalize on further down the road, were marked as determining factors by less than 20% of respondents.

One other factor that gives us a clearer understanding of this analysis on the “state of the 3D industry” is the different approaches between US and European-based professionals, which make up 91% of the study’s respondents. Sculpteo, which divides itself between Paris and San Francisco is naturally interested in finding out about both. The perception is that Americans see 3D printing technologies as a way to allow anyone to produce better products, while Europeans see it as a way for high-end professionals to make even better products than before.

Leave A Comment