Headquarted in Belgium, Luxexcel has announced it has received $10 million in investment funding for its 3D printed lenses.

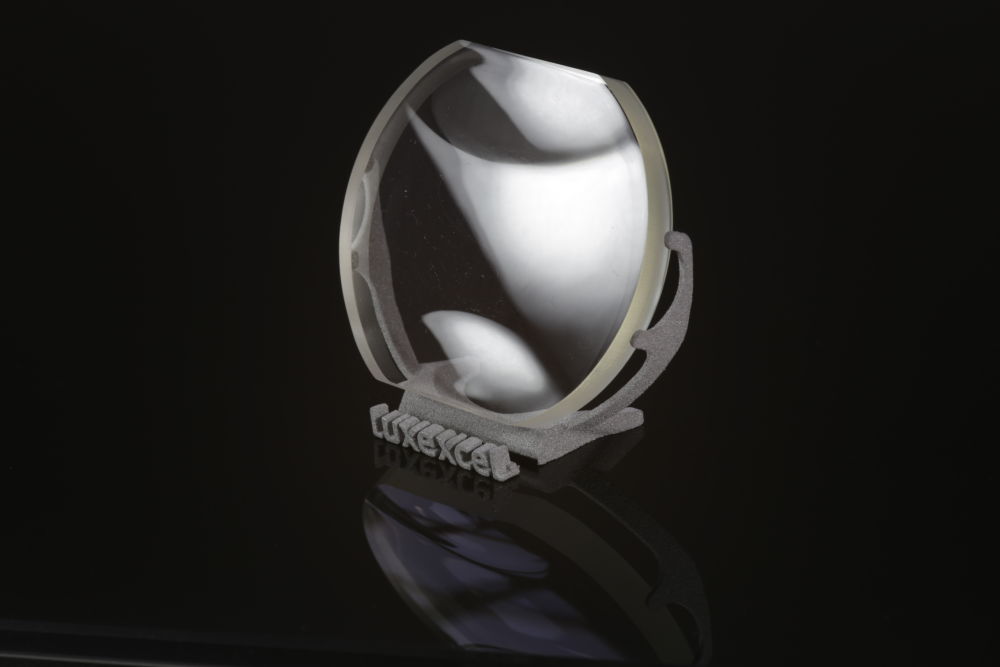

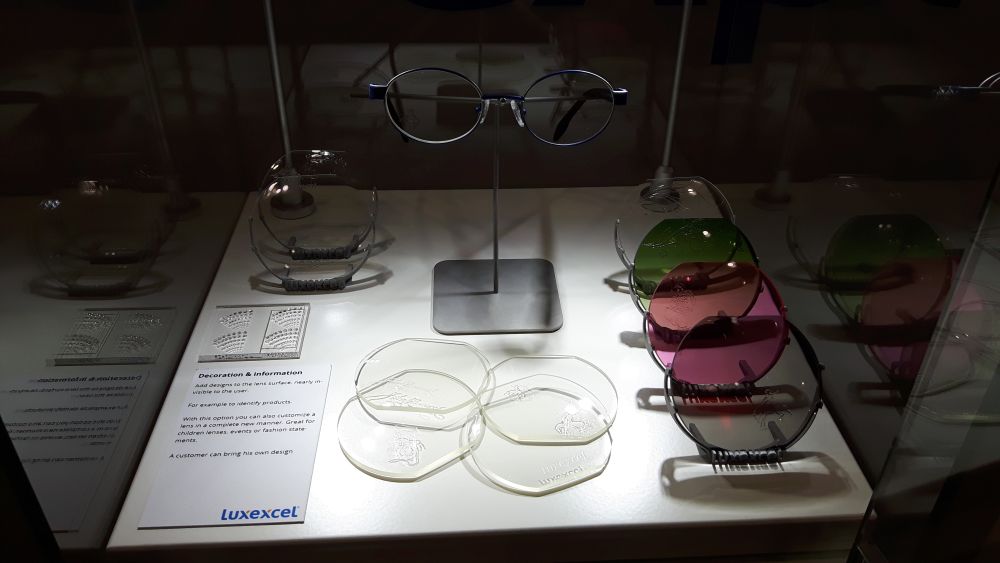

The company has recently received certification from the International Organization for Standardization (ISO) for their 3D printed ophthalmic lenses and expect this funding to support shipment of their 3D printing platform to ophthalmic labs. Luxexcel’s technology uses 3D printers and acrylic material to create transparent lenses with “quality, straight out of the printer, is at industry required ISO quality level.”

Equity funding

Luxexcel received investment from KLA-Tencor Corporation in California, as well as continued investment from SET Ventures in the Netherlands, German based Munich Venture Partners and the Flemish regional investment fund PMV.

CEO of Luxexcel, Hans Streng, spoke regarding the investment,

This investment by a group of renowned investors combined with the strategic cooperation with KLA-Tencor is of key importance to our business development. It enables us to bring high quality industrial 3D printers to the ophthalmic market and it shows great confidence in our business strategy.

3D printing platform

Receiving approval from the ISO was an important milestone from Luxexcel and now with this investment the company can begin shipping the 3D printing platform later in 2017. Luxexcel’s 3D printing platform includes industrial grade 3D printers, the lens design software and workflow integration tools. The company introduced the platform at Vision Expo East 2017 in New York, along with the first showcase of the lenses.

Future of lenses

CEO Hans Streng explains the importance of the funding to move the company forward, “we have experienced an exponentially increasing interest and market pull both from the ophthalmic market as well as related industries such as Virtual and Augmented Reality.” Streng also stating that,

The cooperation with KLA-Tencor and its global track record in the semiconductor-tooling industry gives a major boost to our smart-glasses roadmap. We are now ready to scale up, deliver and disrupt…exciting times.

As mentioned by Streng, the ability to 3D print transparent lenses opens up new applications with the creation of different lens shapes. This is something Industry has seen recently with research from Germany into the 3D printing of glass.

Also, US research facility Lawrence Livermore National Laboratory has developed a new method for creating 3D printed glass structures. However, LLNL do not intend to create ophthalmic lenses but instead harness the increased design freedom to expand the shape of optical lenses for lasers and other similar devices.

The Industry Awards is now just weeks away, so make sure you place your votes to decide this year’s winners.

To receive the latest 3D printing news, sign up to our newsletter and follow us on twitter and Facebook.

Featured image showcases the 3D printed ophthalmic lenses. Photo via Luxexcel.

Leave A Comment