Netherlands-based independent 3D printing resin manufacturer Liqcreate has unveiled its latest resin, Liqcreate Rigid Pro. The new material targets specific use cases where solutions were previously sparse.

Liqcreate Rigid Pro is a black photopolymer resin purpose-made for engineering applications. This resin is formulated to provide chemical resistance, high-temperature tolerance, and significant strength and rigidity. These characteristics make Liqcreate Rigid Pro a versatile material suitable for use in various industries, such as engineering, automotive, electronics, and oil & gas.

A chemical-resistant and heat-defiant resin for versatile applications

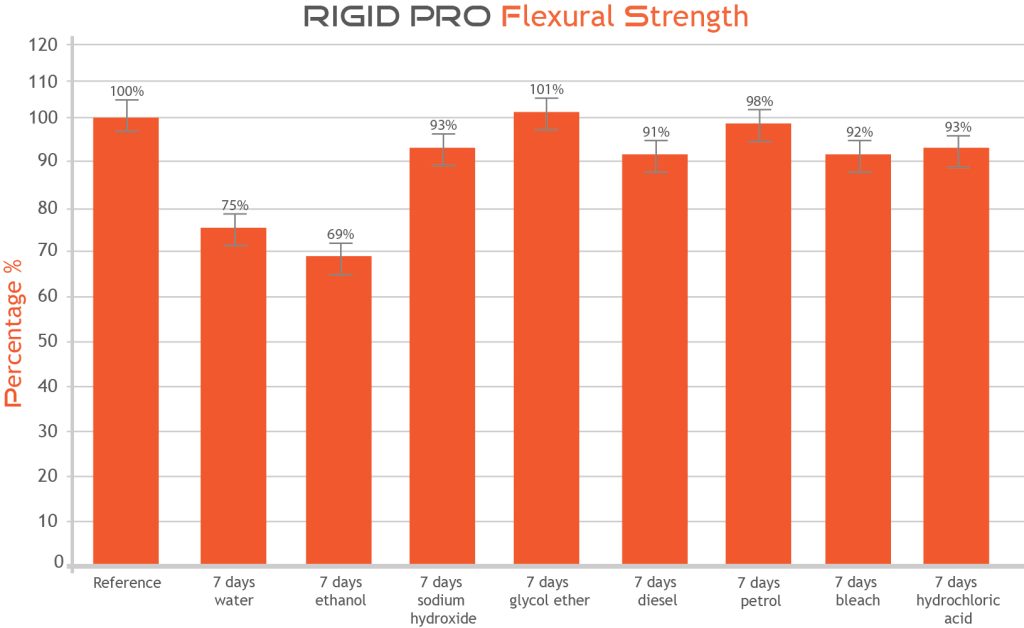

One of the key features of Liqcreate Rigid Pro is its resistance to a variety of chemicals, including mild acids and bases, as well as petrol and diesel. This property positions it as an ideal material for applications in the oil and gas industry, as well as the chemical sector. The ability to design and produce custom chemical-resistant parts within days offers a cost-effective solution that was previously unavailable, says the company.

Liqcreate chemical vs flexural strength test table. Image via Liqcreate.

Liqcreate chemical vs flexural strength test table. Image via Liqcreate.

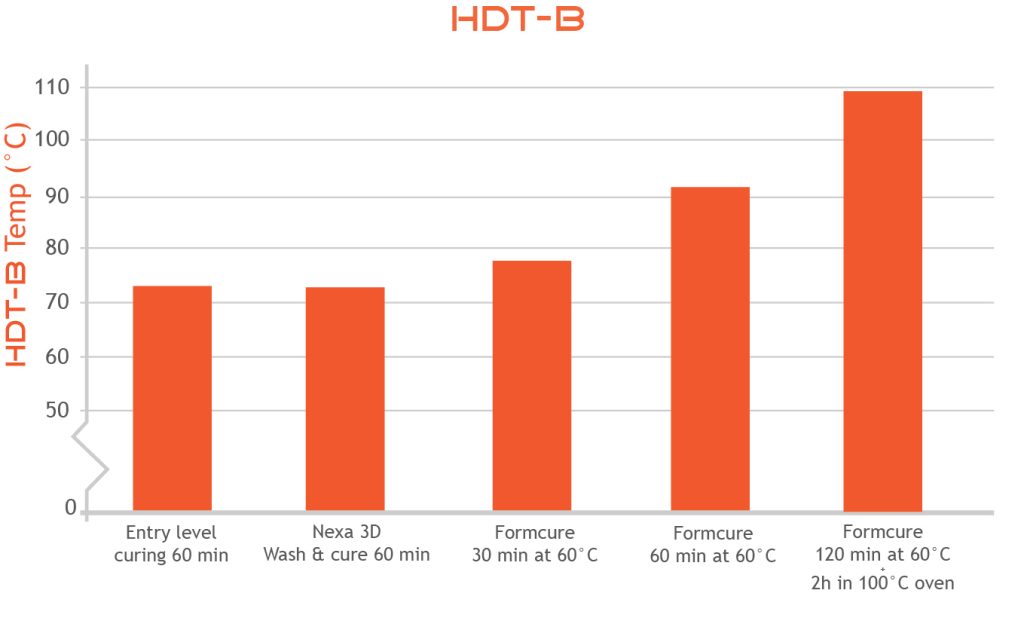

Moreover, the heat deflection temperature (HDT-B) of Liqcreate Rigid Pro is 77°C after post-curing with UV light using an entry-level curing unit. This value can be significantly enhanced to 91°C using a Formlabs Form Cure or equivalent unit, which UV cures and heats at the same time. An optional thermal curing step can further elevate the HDT-B to 109°C. These properties make the resin suitable for applications requiring good thermal resistance, such as automotive under-the-hood components and medium-temperature casting and molding.

Due to its combined chemical resistance, high-temperature tolerance, and superior 110 MPa flexural strength, Liqcreate Rigid Pro finds applications in custom machining and factory equipment parts. Machining industry parts subjected to static loads can be designed, 3D printed, and post-processed in a single day, thereby eliminating the need for a substantial inventory of spare parts.

For users seeking resin compatibility within a 385-420nm wavelength range, Liqcreate Rigid Pro presents a viable option. This includes Digital Light Processing (DLP), Liquid Crystal Display (LCD), and laser-based systems, functioning within a wavelength range of 385-420nm. The resin’s versatility extends to working with entry-level machines from brands like Anycubic, Elegoo, and Creality, as well as professional systems from Asiga, Nexa3D, and UnionTech Martrix. Details on specific printing parameters can be found on the Liqcreate website.

Liqcreate’s customization and collaboration drive

Manufacturing on Demand

Customization options are available for Liqcreate Rigid Pro, allowing OEM partners to rebrand and optimize the resin for various use cases and 3D printer compatibility. Liqcreate additionally offers custom development services. These services cater to the creation of non-standard formulas tailored to specific applications. Customers can request polymers with specific characteristics, influencing both printing speed and the final product’s properties.

By operating independently and possessing in-house research and development capabilities, Liqcreate fosters smooth collaboration with 3D printer hardware manufacturers. This eliminates potential competition or conflicts, allowing Liqcreate to quickly scale the production of custom resins and deliver large quantities in a timely manner.

You might also like:

CTIBiotech’s project paves the way for sustainable vaccine development: French biotechnology company CTIBiotech has announced the launch of its SAFESKIN3D project.

* This article is reprinted from 3D Printing Industry. If you are involved in infringement, please contact us to delete it.

Author: Ada Shaikhnag

Leave A Comment