Hepburn and Sons LLC, advisors to the American maritime industry, officially joined forces with MELD Manufacturing Corporation, developer of the patented, solid-state metal additive manufacturing process and provider of MELD 3D printing machines. The companies have been working together since 2021 to introduce the Navy and other military services and DoD agencies to MELD, also known as additive friction stir deposition.

Hepburn and Sons LLC is a small business founded in 2010 whose initial focus was to provide expert consulting, engineering analysis, and advisory and design services in the areas of the naval engineering and naval architecture. The company has grown rapidly over the last few years and is now leading research and development efforts for the U.S. Navy, U.S. Air Force, U.S. Army, U.S. Coast Guard as well as the Defense Threat Reduction Agency. In order to execute their mission, Hepburn scouts for innovative small businesses that have technology that can be utilized to support the U.S. defense sector. MELD is one of those unique and innovative companies that have developed and introduced disruptive technology to the U.S. defense sector.

The CEO of Hepburn and Sons LLC, Scott Hepburn noted “Together, Hepburn and MELD will quickly transition advanced, large-scale metal additive manufacturing capability to our nation’s defense manufacturing and repair organizations to rapidly improve our warfighting capabilities at a reduced cost and schedule.”

Manufacturing on Demand

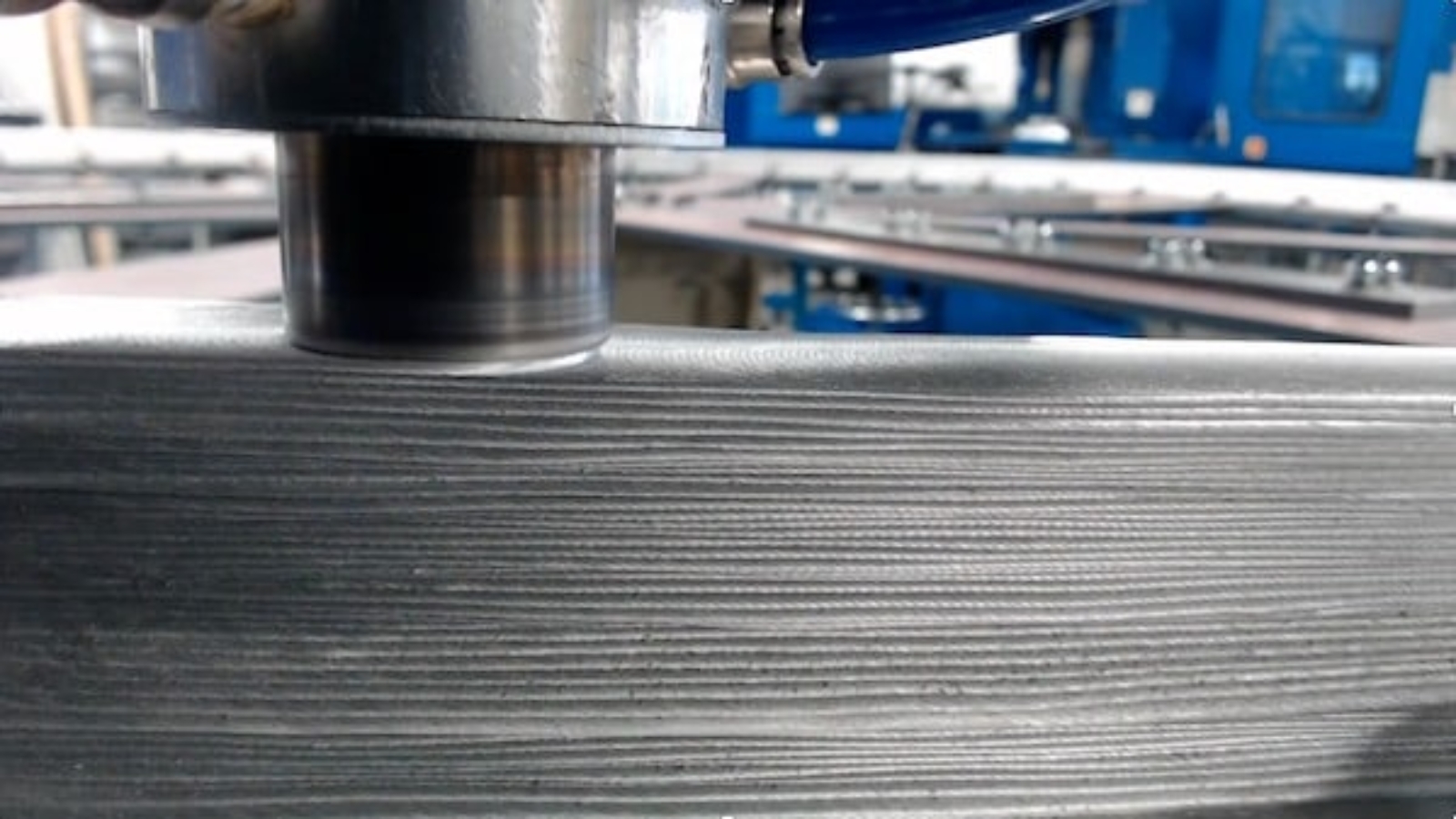

MELD Manufacturing Corporation was founded in 2018 and has developed a no-melt additive manufacturing process for metal, offering stronger, better parts. No melting also offers the potential to work with un-weldable materials. This freedom offers the ability to rethink how particular materials are used for various applications and in what combinations. MELD is situated to address several challenges within the defense industry including lessening supply chain disruptions caused by scarcity of metal spare parts and reducing repair and rework backlog caused by long lead times for back-ordered parts. MELD ensures rapid repair capability to quickly return material to service. On-site use of a MELD machine will ensure a more streamlined production control process saving time, money, and effort. The implications of introducing it into defense component manufacturing is a game changer.

The Hepburn and MELD team recently won two research projects supporting both the U.S. Air Force and the U.S. Navy. For the Air Force, the Hepburn MELD team was selected for phase two of a small business innovative research program (SBIR) project. The overall objective of this project is to prove how MELD can improve productivity and reduce the cost of components used in low-cost, attributable unmanned aerial vehicles (UAV) as well as to address the sustainment of existing critical UAV inventory.

For the Navy, the team was selected for a National Shipbuilding Research Program (NSRP) research & development project, as part of the program’s continuing mission to reduce costs associated with U. S. shipbuilding and ship repair. Through this project, the team will use MELD to additively manufacture flight deck tie-downs. Though seemingly benign, the cost of manufacturing and long lead times for flight deck tie-downs, particularly those installed in ships with aluminum flight decks, is significant. Coupled with the fact that thousands of these tie-downs are installed or replaced by the Navy every year, the team believes they can maintain the geometry and function of the standard item while using MELD to rapidly print these tie-downs, significantly reducing cost and schedule by implementing a print-on-demand approach to manufacture low-cost, high-volume parts, such as the flight deck tie down.

Based on these two recent wins and having a number of opportunities in the works, Hepburn and MELD committed to formally taking their relationship to a new level. The CEO of MELD, Nanci Hardwick, said, “What makes this team so valuable is the combination of technology and the expertise needed to field that technology. MELD offers the ability to reshore production of critical components and Hepburn offers the experience and know-how to transition technology quickly and effectively.”

Through their new relationship, the Hepburn MELD team believes they can utilize MELD technology to help resolve challenges in the Navy and in the U.S. defense sector generally including supply chain disruptions caused by scarcity of metal spare parts along with long lead times on parts that result in the excessive backlog. With MELD, parts can be printed in hours or days as opposed to months or even years. The uniquely open-air process can not only be used to print critical metal components but MELD can be used to repair damaged parts in the workshop or in the field, even with non-fusion weldable alloys.

You might also like:

Vast and Launcher join forces to conquer space: Launcher founder Max Haot will join as the President of Vast to help execute the company’s vision. In this new role, Max Haot will oversee the Orbiter, E-2 and space station programs as well as engineering, manufacturing, marketing, finance, and facilities teams. Tim Berry is also joining Vast as Vice President of Manufacturing and will continue to lead the Manufacturing, Supply Chain, and Quality organizations.

* This article is reprinted from 3D Printing Media Network. If you are involved in infringement, please contact us to delete it.

Author: VoxelMatters

Leave A Comment